Most experts would tell you that Additive Manufacturing’s ability to deliver lightweight structures can be mainly achieved through lightweight design. Considered one of the most promising methods to achieve this objective, lightweight design is made possible via topology optimization or generated lattice structures. For those who would like to achieve this objective while improving the part’s mechanical properties, a recent conversation at Formnext 2024 sheds light on a solution that could help meet these objectives at the post-processing stage: Continuous Fibre Injection Process (CFIP).

In the list of tasks that fall under the umbrella of post-processing, most solutions we identified aim to improve the part’s mechanical properties only. While Continuous Fibre Injection Process (CFIP)’s first goal is to reinforce the part, I believe this ability to do so while facilitating the use of lightweight materials should not be underrated.

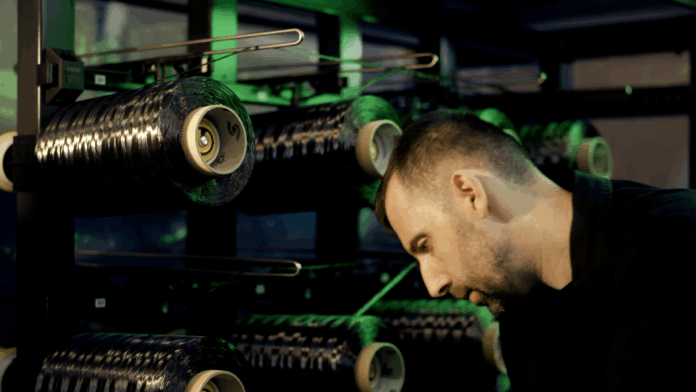

Developed by Reinforce3D, a spin-off of research institute Eurecat, CFIP works by enhancing “the mechanical performance of parts through the strategic placement of continuous fibers, such as carbon or glass fibers, within the structure of a component.”

Blanca Garro, CEO of Reinforce3D explains that “unlike traditional methods, where fibers are embedded during molding or layered during printing, CFIP involves injecting continuous fibers into tubular cavities pre-designed into the part.

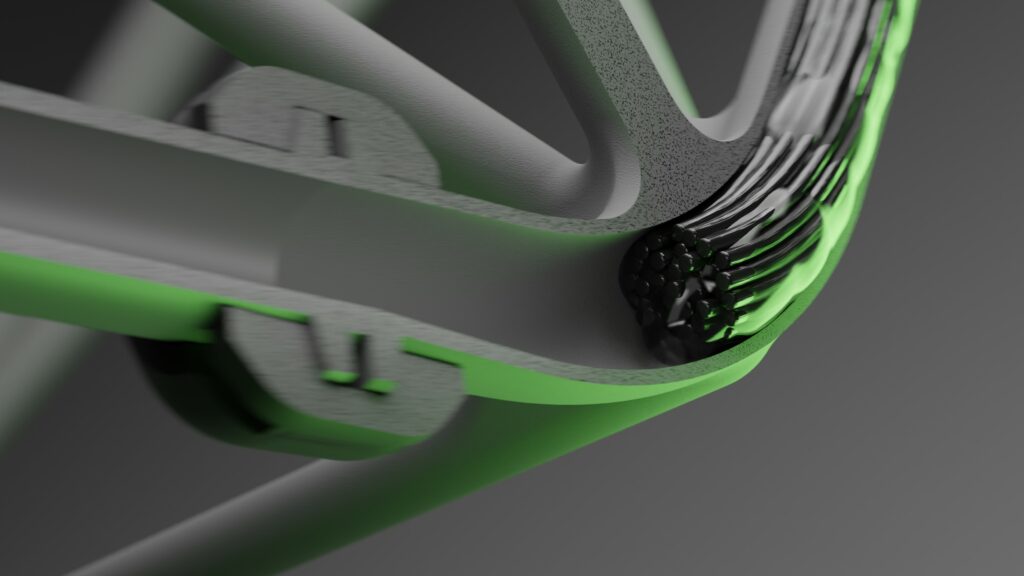

The process begins with a 3D-printed or pre-manufactured component featuring internal channels or cavities. These cavities act as pathways for the fibers. During the CFIP process, continuous fibers are injected into these channels along with liquid resin. The resin flows alongside the fibers, filling the cavity completely. Once cured, the resin solidifies, creating a robust mechanical bond between the fibers and the part material. This bond reinforces the part’s structural integrity, resulting in significantly higher strength, stiffness, and durability compared to standard non-reinforced parts.

CFIP’s moldless nature eliminates the need for additional tooling or complex molds, streamlining the production process. This approach allows greater flexibility in design, making it possible to reinforce components with complex geometries or multi-directional stress requirements.”

The post-processing solution may have first been developed with AM in mind, but it is actually compatible with other manufacturing processes. “CFIP can inject fibers into molded components with pre-designed cavities, significantly improving their strength and reducing their weight,” Garro notes. Given the need for weight reduction and strength across demanding industries, and AM’s ability to deliver complex geometries that other technologies can’t do, I will not be surprised to see CFIP shine when integrated with AM.

On this note, we learned from Reinforce3D that their technology works with parts manufactured with Multi-Jet Fusion, SLS 3D printing, Stereolithography (SLA) as well as Metal and Ceramic Additive Manufacturing. Although the exact metal and ceramic AM processes CFIP can work with have not been mentioned, one should already recognize here the post-processing solution’s potential: unlike other solutions that are compatible with either polymer or metal 3D printing, CFIP seems to be able to address a wide range of manufacturing requirements. This should be a cost advantage for manufacturers who utilize different AM processes.

“CFIP allows fibers to be injected along complex trajectories, even though layers in 3D-printed parts, enable reinforcements in directions that were previously unachievable. This precision and adaptability make it suitable for critical load-bearing applications and components subjected to multi-directional stresses,” the CEO adds.

Applications, Industries

If you’re a regular reader of 3D ADEPT, you probably already know that we start believing in a specific technology once we discover what it can do. Reinforce3D told 3D ADEPT Media they are working on several collaborations spanning product development (where the goal is to create applications with superior strength-to-weight ratios), production of obsolete or replacement parts, and engineering high-performance components.

Speaking of obsolete or replacement parts specifically, Garro said that “these clients typically possess digitized catalogs of parts, but traditional additive manufacturing has not met the technical requirements needed for functionality. CFIP, however, provides the performance enhancements necessary to fill this gap, offering a viable and cost-effective solution.”

While we hope to see these applications soon, we can already share the technology has proven its legitimacy by winning multiple awards including the JEC World Innovation Award in 2020 with a brake pedal made with continuous carbon fiber. This application has demonstrated CFIP can integrally join different parts with fiber continuity between them, thus providing very high-performance joints. This allows for multi-material and multi-process structures by selecting the most efficient material and process based on the requirements in each area of the structure.

“Across all these collaborations, the unifying goal is to harness the unique benefits of composites. Clients are utilizing CFIP technology to add resistance, reduce weight, or achieve precise reinforcement, unlocking a level of design freedom and mechanical performance not previously possible with conventional methods,” Reinforce3D’s spokesperson said.

Given CFIP’s ability to work where lightweight, high-strength parts are required, it makes sense to see Reinforce3D target the aerospace, automotive, defense, medical, robotics, and sports industries.

More specifically, the technology is ideal for post-processing structural components, UAVs, and interior parts. It provides lightweight reinforcement for vehicle parts and medical devices, including bio-compatible implants. It also strengthens robotic arms and frames without compromising precision or agility. Additionally, high-performance sports equipment—such as bicycle frames, tennis rackets, and protective gear—benefits greatly from continuous fiber reinforcement.

“While CFIP represents a breakthrough in composite reinforcement, like any cutting-edge technology, it has some current limitations. These challenges are primarily related to the physical and operational parameters of the process, which are defined in our comprehensive design rules. Some of the key areas include curvature radii of trajectories, injection speeds, reduced diameters and maximum trajectory lengths, scalability for ultra-complex designs.

Despite these limitations, our R&D team is fully committed to addressing and minimizing them. We are constantly refining the technology to broaden its capabilities, improve user experience, and expand the range of applications it can serve. With ongoing advancements, we are confident CFIP will continue to set new standards in composite manufacturing,” Garro concludes.

Editor’s notes

CFIP is already available for commercialization. Reinforce3D has developed a 360º solution ecosystem to support industries that adopt its technology. This includes a Delta Unit, a design checker software, and patented fibers – all of this backed by a team of experts dedicated to helping companies integrate CFIP into their workflows and achieve optimal results.

For the record, the Delta Unit is at the heart of the solution; the design checker software is a proprietary tool that optimizes fiber trajectories and validates designs for CFIP compatibility, and patented fibers are specially engineered fibers and resin systems tailored for maximum mechanical performance.