Vexma Technologies, an India-based 3D printing service bureau, recently explored HP Multi Jet Fusion (MJF) for the manufacture of a pickleball.

As a reminder, four years ago, Azul3D and Wilson proved it was possible to leverage AM for the manufacture of a pickleball, using a proprietary high area rapid printing (HARPTM) technology, which is another version of stereolithographic printing.

Vexma reminds that traditional pickleballs have been manufactured through injection molding or rotational molding, both of which enable mass production. However, these methods come with significant drawbacks that affect the overall playing experience and longevity of the product.

According to the Vexma team, common issues with regular pickleballs often include noise pollution, breakage and durability issues, lack of spin control, or even material wastage at the manufacturing level.

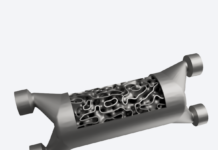

Using HP MJF allows the team to create a product with superior integrity and precision. “This method minimizes waste, enhances material strength, and ensures consistent quality. The result? A pickleball that’s lighter, stronger, and quieter than ever before,” Vexma said.

With a new design that allows players to fine-tune ball speed and apply spin with greater accuracy, Vexma said this 3D printed version of the ball is indestructible and helps to ensure consistent performance. The material used would absorb impact more efficiently, significantly reducing noise levels.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.