If you are a regular attendee of a given event – be it as an exhibitor or as a visitor -, comparison between your previous experience and the new one is somehow inevitable. When I arrived at the 2022 edition of Additive Manufacturing Forum (AMF), I couldn’t help but think that “the last time, I was at this event, Belgium had announced its first confinement the day following the end of the conference”. However, throughout this 2022 edition, the encounters with new and familiar faces – with both attendees and exhibitors, the keynote speeches as well as the evening reception and flying dinner, my first thoughts eventually evolved to provide room for a stronger idea that has become a common thread running through my conversations: AMF now has a clear strategic positioning in the local AM industry.

I remembered my very first conversation with Tobias Schmidt, Partner & Barbara Weingarten, Senior Project Manager at IPM AG – organizer of C-level and B2B conferences such as AMF; a conversation that described AMF as a Germany-focused event with the ability to rapidly raise the interest of international companies that are looking for business opportunities in the DACH region, hence the adaptation of communication supports in both English and German and the integration of simultaneously interpretation during the keynote speeches.

The 2022 edition remained faithful to this hybrid concept. The event remains a local tradeshow, that highlighted the strengths of Berlin as the “capital of Additive Manufacturing”; exhibitors mostly came from the DACH region, and keynote speeches and panel discussions included a good mix of both local and well-established international players.

Overall, rather than focusing on industry topics, this coverage lays emphasis on 4 key facts:

- What made Berlin a solid ecosystem for AM;

- The importance of related services for AM integration;

- Product launches and newcomers in the AM industry;

- And eye-catching applications on the show.

Key facts

1- Berlin has a solid ecosystem that can drive the adoption of AM

In 2020, a report from SmarTech revealed that Germany was the country that invested the most in AM technologies with $ 1.28 billion generated in terms of revenue in 2019. Interestingly, amid the various regions of Germany that have attracted both national and international companies, Berlin remains one of the rare regions that keeps highlighting the benefits of incorporating a business within the capital. These benefits go beyond the international nature of the city which makes it easy for professionals from different backgrounds and languages to work. Furthermore, these benefits encompass the solid ecosystem of entrepreneurs, the various initiatives offered in the region, the economic development clusters, as well as the various research institutes that boost innovation in the region. In a nutshell, the region is home to an interesting value chain covering all aspects of additive manufacturing from R&D and software and printer producers to material suppliers and global networks for professional 3D printing.

This promotion of Berlin as the “capital of AM” is something that is always brought to the fore of AMF through the initiatives of Berlin Partner, a Berlin Business Development Agency that provides specific services tailored to the unique needs of each business looking to settle down in the capital.

At AMF especially, a few companies supported by Berlin Partner were gathered on a noteworthy booth in order to showcase their products and services to visitors. There are:

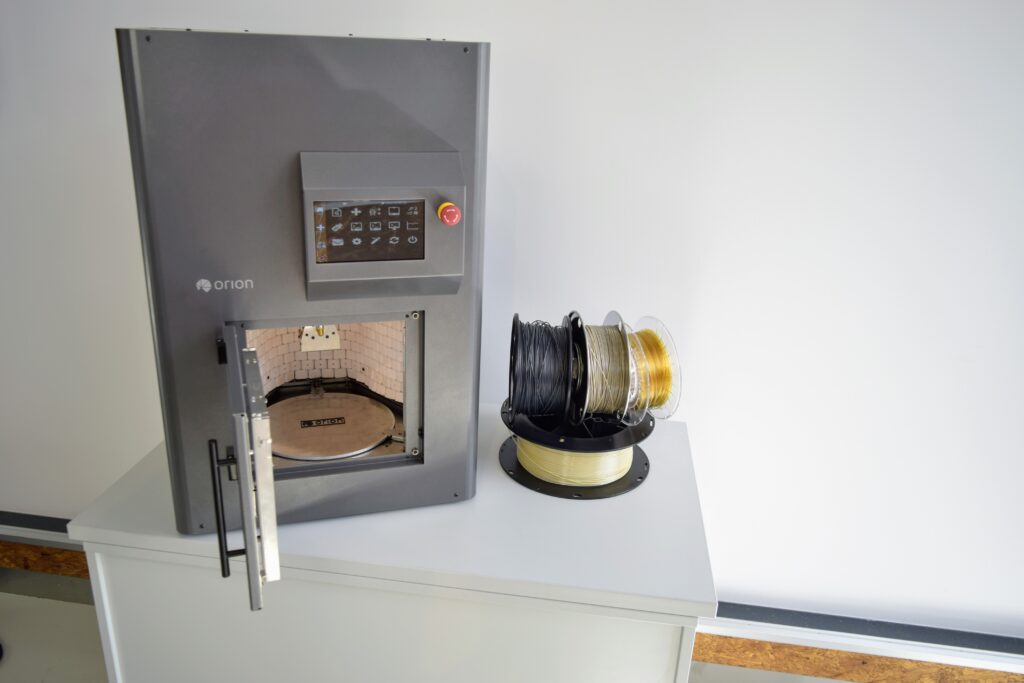

- Orion Additive Manufacturing, a company that develops a technology that combines FFF with thermal radiation heating to produce patient-specific implants, surgical instruments, aerospace parts to name a few. By processing high performance polymers, Orion can achieve parts that are as durable as metals, can be comparable to injection molded parts in strength and which can be used across a wide range of industries. Founded in 2018, the company’s A150 additive manufacturing system was officially launched last year and can achieve a print speed of 10mm/s – 400mm/s, an extruder max temperature of 500℃, reach a bed max temperature of 300°C and a TRH* (Thermal Radiation Heating) temperature of 300°C.

- Xerion Berlin Laboratories,a company that prides itself on developingthe complete ecosystem for metal/ceramic FDM. We first discovered the company when it launched the Fusion Factory, a machine that combines a 3D Filament Printer (FFF principle), a Debinding station (which functions on the principle of solvent removal) as well as a Sinter furnace. During the past years, Xerion has expanded its services to develop high tech thermal systems that can be tailored to organizations’ needs.

- Werner-von-siemens centre for industry and science e.v,a research cooperation that focuses on exploring the developments in new materials, AM and digitalization. A 600 million Memorandum of Understanding (MoU) signed between the Berlin Senate and Siemens in 2018 gave birth to a common cause: the establishment of an industry and science campus that would address requirements of both dedicated core technologies and specific fields of application in the energy sector. In 2019, the name Werner-von-Siemens Centre for Industry and Science was given to this non-profit association which gathers 12 partners involved in this journey.

2- The importance of related services for AM integration.

This importance of related services was a key trend during the 2020 edition of the event and it’s one that usually goes beyond the regular value chain that usually focuses on “Software-3D printers-materials-and post-processing”. During this 2022 edition of AMF, two companies drew my attention as they focus on current challenges and trends faced by AM users. It was also the first time that they exhibited at AMF:

- MakerVerse. Launched at the beginning of the year, the company is a joint venture of Siemens Energy, ZEISS, and financial/venture capital investors, including 9.5 ventures. It positions itself as a one-stop shop that provides fast and reliable access to advanced on-demand manufacturing services. Building a digital platform that can connect players across the globe is a need that has become blatant with the Covid-19 pandemic. A quick conversation with Christian Matzen, CRO, reveals that the team will first focus their activities on Europe. We currently have little information about how the platform stands out from the crowd. However, we do know that it integrates a broad material and technology portfolio (L-PBF, SLS, MJF and FDM), performs automated manufacturing feasibility checks, and matches requests with the right partner in order to deliver production with industrial grade quality standards. Matzen also mentioned the multi-year agreement they just signed with ZEISS to accelerate and promote the widespread adoption of industrial grade additive manufacturing. This means that the platform will rely on a multi-tier quality assurance process that meets the entire spectrum of requirements from prototyping towards end use parts.

DataForce by TRANSPERFECT. At first glance, when walking through the aisles of an event like AMF, Dataforce will likely not be the first company’s booth where you would stop by, especially if you are the kind of visitor who is always attracted by a nice 3D printed part, a beautiful machine or an intriguing material. What they do is not visually tangible, but remains invaluable. What raised my attention to this company is their name “DataForce”, which in my opinion gives a hint about their core business: data. Do I need to remind you that discovering and making the most of data that enable to deliver sustainable AM applications is one of the key challenges that remains to be addressed in this industry? Well, DataForce is a global data collection and labeling platform that combines technology with a diverse network of more than one million data contributors, scientists, and engineers. With secure and reliable AI services for structured data, DataForce debuts on a market where the use of AI has been rife, with organizations looking to leverage the predictive power of machine learning. One of the key areas of applications that is well known by the industry and where the company currently focuses its activities is process control, an area that Director of AI, Alexander Woellwarth-Lauterburg discussed in the panel “AI in Additive Manufacturing: Potentials for Quality Assurance”, by highlighting the necessity of good quality data for production line and QA. (Indeed, amid its various uses, AI and machine learning algorithms are well acknowledged for either defect detection or parameter modulation purposes (or both), all with the intent of reducing print failures and saving on time and material costs.)

3- Product launches & other newcomers in the AM industry

What would be an AM event without any product launch? Despite the participation of a great number of well-established industrial companies, we focused our interest on companies that were relatively new on the market and that were showcasing for the first time at AMF 2022.

AM company Roboze is definitely not a newcomer in the industry, but it’s interesting to note that for its premiere at AMF, it officially launched its Roboze Professional series, a package that integrates its proprietary software, Prometheus, and new materials. The PRO series consists of two solutions: One PRO and Plus PRO. Compared to the previous professional series, these two systems see an integration with Roboze Prometheus slicing software, developed for end-to-end workflow management, from the early design stages to the final production of the printed part. The software has strategic printing profiles that allow prints up to 2 times faster, compared to the industry average, with the UltraFAST profile, to obtain tools to support production lines with the material Carbon PA, PA loaded with carbon fiber, and to shorten the concept validation phase with ULTRA-PLA technical material, Roboze explains.

Moreover, the Prometheus’ UltraQuality profile is added for the production of components in PEEK, Carbon PEEK and ToolingX CF (the latest two being the new materials added to the Roboze family of super polymers and composites). While these materials can be familiar to certain AM users, Roboze precises that what makes their use outstanding with the PRO series is that they can achieve more than just functional prototyping, and enable production of strategic parts through an optimized, cost-effective, and rapid workflow.

Other companies that showcased for the first time and that introduced their latest products and services include AMAZEMET, Sindlhauser Materials GmbH, GROB and Q.big 3D GmbH.

Polish technology company AMAZEMET Sp. z o. o. targets both R&D and institutions by providing dedicated material solutions for LPBF to the AM industry as well as specific atomization solutions. The company showcased a small atomization solution on its stand. While I believe the role and advantages of atomization for AM requires a dedicated article, my conversation with Cofounder and CEO ŁUKASZ ŻRODOWSKI highlights the factthat this process enables to adjust powder characteristics using different ultrasonic frequencies. Moreover, while it greatly depends on particle size between frequencies, one of the long-term benefits of this process certainly remains its ability to deliver on the promise of sustainability – as it can also transform scrap into materials. With four technologies developed to date, AMAZEMET currently focuses on metal powder, vacuum technology, ultrasonics and post-processing.

On another note, Volkan Yavuz and Rodrigue Ngoumeni hosted professionals who were keen to discover Additive Manufacturing with nanoparticles on Sindlhauser Materials GmbH’s booth. Acknowledged for its advanced materials that aim to enhance coating performance, Sindlhauser Materials GmbH delivers its services to a wide range of industries which can both leverage conventional and AM processes. The thing is, nanomaterials designed for AM are usually most discussed in R&D projects. Sindlhauser Materials GmbH’s presence at AMF 2022 made me realize that we might be reaching a turning point that would lead to viable commercial applications in the industry. Nevertheless, attention is to be made on the difference between applying 3D printing to nanotechnology and applying nanotechnology to 3D printing.

The former describes the complexity and design flexibility of nanoscale structures using AM, as partially seen in the dossier of the May/June edition of 3D ADEPT Mag that discussed micro-AM technologies. As Ngoumeni told us, the latter consists in improving characteristics of 3D printed parts using nanomaterials’ advanced and customizable properties. Sindlhauser has built up expertise in this area. This means that they incorporate nanoparticles (NPs) into the traditional 3D printing host material (e.g. polymer or ceramic matrices) to create a nanocomposite which can be used as a feedstock material in 3D printing processes such as FDM and selective laser sintering (SLS). Sindlhauser has developed a patent-pending solution for the industry.

GROB-WERKE GmbH & Co. KG, short for GROB is another newcomer in the AM industry. Acknowledged for its machining centers, assembly systems, electro-mobility and automation solutions, GROB decided to position itself on the very selective and niche market of Liquid Metal Printing. In order to overcome the challenges of Powder bed fusion (PBF), the GMP300 (where GMP stands for GROB Metal Printing, and 300 for the size of the work area) is equipped with 3-axis kinematics and can achieve maximum axis speed of 30 m/min. The inert atmosphere protects the component from oxidation, guaranteeing consistently good material quality. The metal 3D printer processes wire as raw material, which enables to save costs at the material level and at the equipment level. Indeed, the use of wire poses no health or explosion hazard, making personal protective equipment worn simpler, and omitting additional work steps such as component de-powdering and the sifting and processing of the powder.

The LMP process is a micro-casting process and not a welding process, having little to no thermal warping. This allows for processing of non-weldable alloys. The LMP process generates a homogenous microstructure with yield strengths equal to or also sometimes greater than the raw material values. In addition to this, the process provides impressively high flexibility and productivity. Flexibility is achieved by the ability to change materials quickly with no excessive cleaning effort, by the highly variable drop diameter and by the ability to change both printhead and nozzle during the build-up process. The high productivity of the LMP process is won primarily via the achievable high build-up rates, the reduced post-processing work, and the fact that the component costs scale to only slightly above the filling level of the construction base, the company says.

Next in this line is Q.big 3D GmbH, one of the latest newcomers we won’t forget any time soon. Founded in 2018, the 3D printer manufacturer positions itself on the market with Queen 1, its flagship product dedicated large scale 3D printing. At the heart of the company is a VFGF (Variable Fused Granular Fabrication) technology that processes polymer granulates into one single extruder. The company seems to focus on the DACH region, but as any company in the industry, it can easily expand into the international market.

In addition to the aforementioned companies, it is worth mentioning the presence of Kurtz Ersa that recently launched its Alpha 140 industrial 3D printer and Xact Metal that launched its XM200G metal 3D printer at Formnext 2021. My conversation with CEO Juan Mario Gomez took place right after a professional who was visiting AMF told me he specifically came to look for an “affordable LPBF 3D printer”, a conversation that just confirmed it was legitimately right for Xact Metal to be present on this show. With prices that continuously increase, part producers want to rely on affordable processes that can deliver quality parts. The thing is that using an affordable process often means you have to sacrifice another important part of the process: speed –which is one of the key aspects the team at Xact Metal has decided to improve in their new 3D printer.

4- Applications

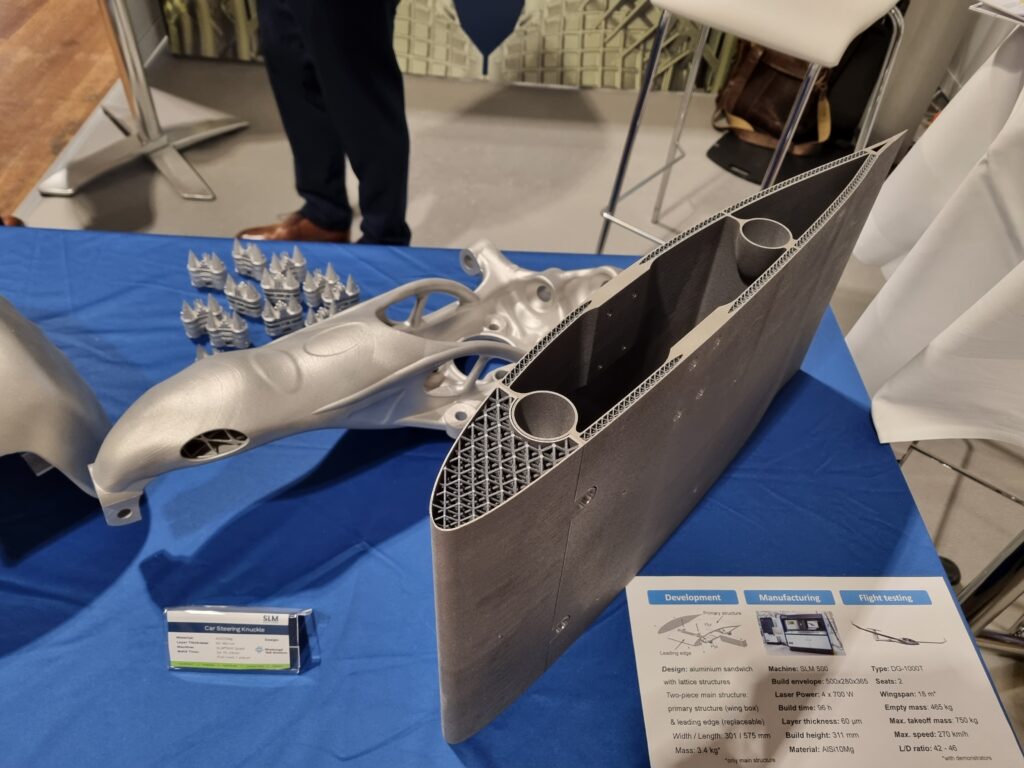

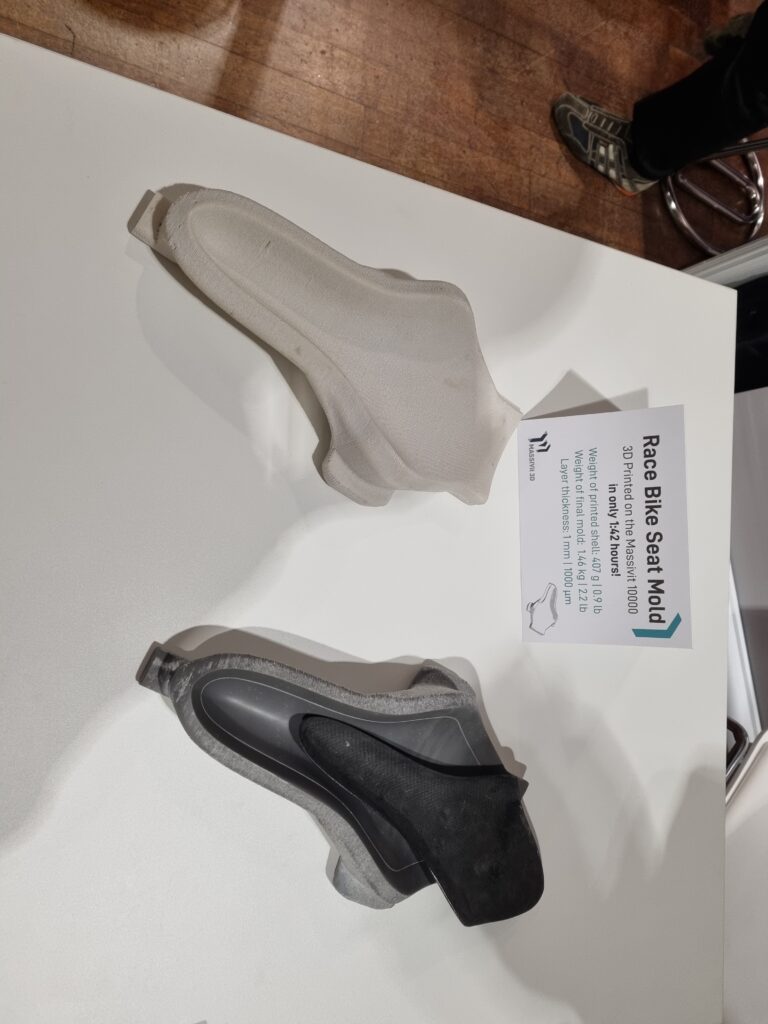

Applications are the best part of every event. Sometimes, they do not need much words as they simply demonstrate the capabilities of a given technology (3D printers, materials or sometimes, even software). Here are a few eye-catching applications we saw at AMF:

A clear strategic positioning in the AM industry: AMF defined as a local event that focuses on conferences and networking.

Industry’s attendance & participation from exhibitors reveal that over 2000 participants (from 41 countries – both exhibitors and visitors combined) partook in the event via the virtual platform and/or an onsite presence.

AMF’s key strength remains its series of conferences and keynote speeches. Most professionals who could be considered as viable potential leads to AM solutions providers told us they attend the event for its conference sessions and presentations, as they are increasingly looking for business cases where AM has proven to be viable. In this vein, one of the conferences that raised interest the most is the one of Anders Such, Head of Additive Manufacturing, MAN Energy Solutions SE who discussed the “challenges in identifying and implementing am business cases” with a focus on the various ways the new generation of printers pushes existing boundaries.

On the whole, it seems that two-thirds of the total number of exhibitors were exhibiting for the first time on the show, after a year gap caused by the pandemic. Some leading companies that were present in 2020 were missing on the exhibition floor. They include for instance Stratasys (that is also founding partner of the event) and BASF. Although they did not have a booth, many big players were represented by their managers and executives. For such players (Evonik represented by Sylvia Monsheimer , AM Ventures’ Arno Held & Adrian Maier-Ring, Sintavia’s Brian Neff) and for certain exhibiting companies like OECHSLER, it is important to be present on this show to network, which is the 2nd most cited argument (after the conference sessions) in the list of reasons why AMF has a strategic place in the industry.

3D ADEPT Media is a media partner of AMF. Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com