Refractory metals are a range of metals that are extraordinarily resistant to heat and wear. This class of materials is considered as one of the most complex to produce given the fact that they require a high melting point as a key requirement for inclusion.

6K Additive, the additive manufacturing brand of 6K, has decrypted the manufacturing secret of these metals as it recently announced the commercial availability of refractory metal powders for additive manufacturing. The materials producer will start providing tungsten, rhenium, tungsten/rhenium and niobium-based powders, ideal for metal AM applications in defense, aerospace and medical industries; in a nutshell, applications that should withstand high-temperature and high-strength.

What I like about 6K Additive, is that they are doing their best to reveal the production process of their materials. A process called UniMelt which uses microwaves to enable a three inch uniform plasma so that each particle that goes through the plasma sees exactly the same temperature, removing the possibilities of satellites and inconsistencies forming during production.

“The uniqueness of 6K’s UniMelt® microwave plasma process, combined with the expertise of our operations team, has allowed us to manufacture production scale volumes for many of the refractory powders like tungsten and tungsten/rhenium. We have spheroidized the full spectrum of refractory powders including tantalum, niobium and molybdenum and we are ready to help organizations advance their applications with these materials”, Frank Roberts, 6K Additive President said.

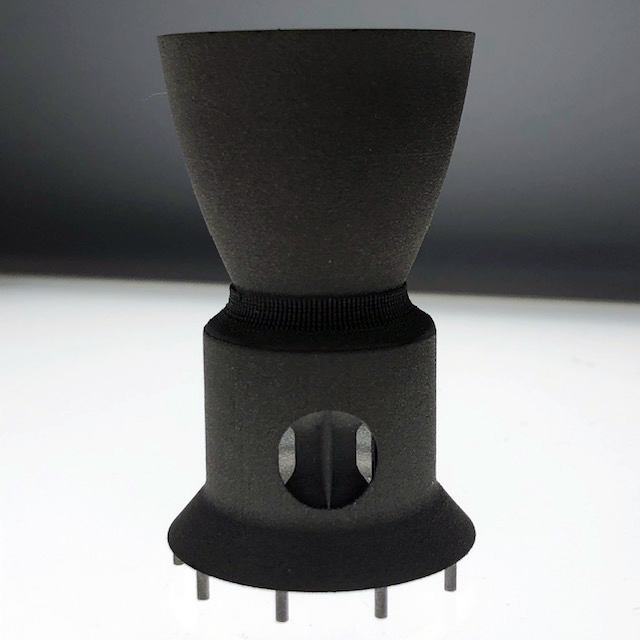

As far as refractory metal powders are concerned, we know from Quadrus Corporation that tungsten/rhenium powder spheroidized by 6K processed exceptionally well in selective laser melting machines. Quadrus Corporation is a US-based company that specializes in commercial software solutions and contract engineering services. The team used spherical tungsten-rhenium to produce a non-eroding throat insert for a solid rocket motor nozzle.

“We have a focus on propulsion applications that require high-temperature, high-strength materials used in modern rocket nozzle applications,” explained Joe Sims, Director of the Quadrus Advanced Manufacturing Division. “Having a reliable, trusted supply chain partner like 6K Additive for refractory materials is critical to our business and to our defense customers. Our powder quality requirements are extremely high and 6K Additive easily cleared that hurdle for us.”

The new refractory materials complete a portfolio that already includes commercially available powders such as Ti6Al4V (Grade 5 and Grade 23), SS316L and nickel superalloys Ni718 and Ni625.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com