A new vague of companies in the AM value chain and the importance of related services

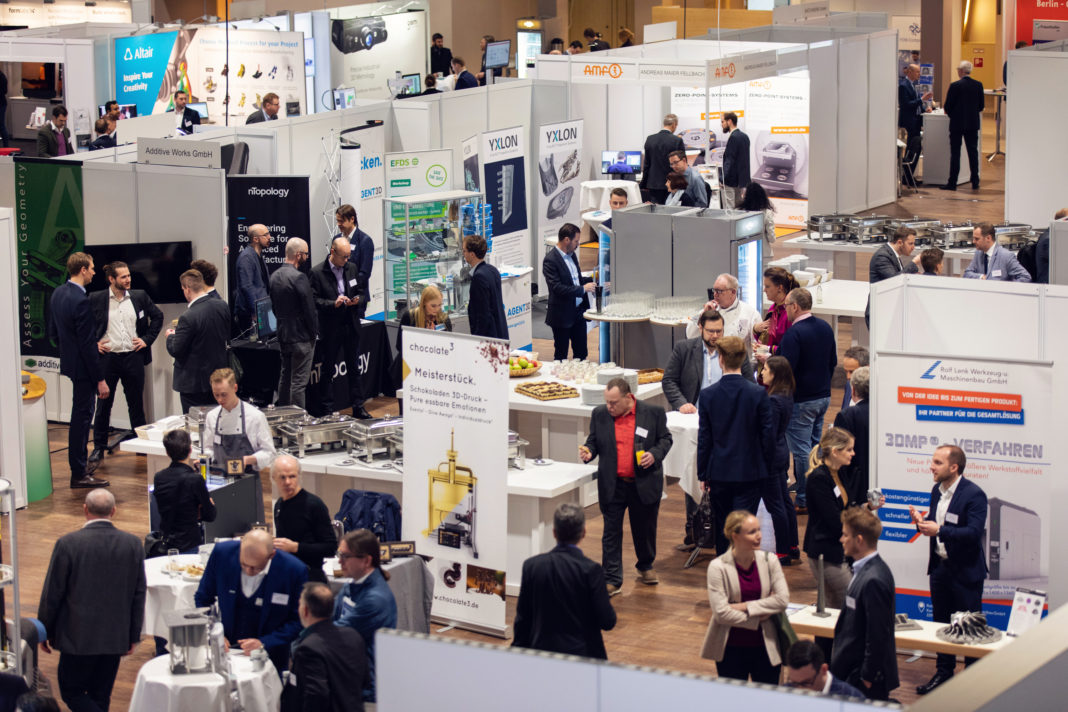

In the midst of several events cancellations/postponements due to the Coronavirus pandemic, IPM AG, with the consent of Neukölln, Berlin-based responsible health authority, held last week the 4Th Additive Manufacturing Forum.

Luckily for all participants, the organizer managed to keep safety as a top priority during the event: hand sanitizers were found at every corner, posters were placed everywhere to remind people to respect the “no-handshake policy” and attendees, consciously or unconsciously, even kept a certain distance between them.

Although booth numbers were not mentioned (making it a little bit hard to find companies), we noticed the absence of a few big names such as Praxair, SLM Solutions, Siemens which had withdrawn their participation to the event in light of recent news regarding the pandemic. On the other hand, it should be noted that this 4th edition attracted several new companies of the industry – mostly Germany-based startups that debut in the additive manufacturing industry as well as British & Australian AM companies, already established in the market (e.g.: AMFG & SPEE3D).

In this vein, the event hosted various interesting profiles in terms of exhibitors:

A new vague of software companies

Choosing its software platform can be as intriguing as choosing the appropriate materials for a printing process. Indeed, companies have to understand the importance of each task in a production workflow and the type of software that can be leveraged at every stage (Design & CAD Software, Simulation Software, Workflow Software or Security/IP software).

Sometimes, they might be lucky enough to find a software company that might provide a combination of various products. This is, in any case, the goal of ELISE GmbH. The open generative engineering platform provides a strong base to operators that would like to leverage modeling and simulation tools.

David Leidenfrost, one of the developers of the company, told us they have been working for several years to respond to a single question: “How to empower engineers so that they develop complex structures in a short time & close the gap between development & production?”

Based on various collaborations with automotive companies and other software publishers, they develop a software platform, whose strength relies on the visual creation of workflows for automated product development.

The start-up secured €3 million in a financing round at the end of 2019 and is getting ready for its formal commercial launch, scheduled for the end of this year.

They are not really new on this market but it is worth to note how much Trinckle has improved its paramate platform. What’s interesting with this design platform is that, the need for CAD expertise is not mandatory, as if in the end, the algorithms were doing the design work for us. This advantage therefore increases the accessibility of the platform to both the final end user and the industrial user.

The integration of new type of companies in the AM value chain and the importance of related services

The AM industry does no longer only include 3D printer manufacturers and their resellers network, material producers, software platforms & 3D Printing service providers.

The 4th Additive Manufacturing platform also highlighted the rise of consultancy firms & engineering offices in this value chain as well as the importance of related services.

AMbitious, for instance, a consultancy firm that mainly operates in the DACH region, is a good example of these new entrants. The consultancy firm is a company of Toolcraft that provides consultancy to companies that would like to leverage metal laser melting technology. The whole team bets on this technology due to its ability to produce complex and efficient lightweight structures, not to mention that the process has been granted Nadcap and TÜV SÜD certifications. A choice they are very proud of as they have recently signed a cooperation agreement with Premium AEROTEC, a company that specializes in the construction of aeroplanes.

Next comes FEM-Composites, a Hamburg-based company that specializes in product development & design with a key focus on fibre-composite materials.

A conversation with Merlin Tamboula, CEO & Founder of the company, laid emphasis on the increasing demand for fibre-composite materials in various industries including aerospace, aviation automotive, railway & maritime. The only thing is that, processing these materials can be quite challenging as they require a specific handling in the manufacturing process to get the desired properties in the manufactured parts. More importantly, these segments increasingly require the production of light-weighted structures that are ideally produced using additive manufacturing technologies.

FEM-Composites’s role therefore consists in, but is not limited to, simulating the use of fibre-composite materials, and predicts any defects that might occur during the manufacturing process, analyzes the properties of these materials, especially their resistance and stiffness in the manufactured component.

As per the words of the CEO, showcasing at the 4th AM Forum enabled the company to officially debuts in the AM industry, to get an overview on what’s really going on in this industry and more importantly, to raise awareness on the real use cases of fibre-composite materials in the field. As fibre-composite 3D printing is currently gaining momentum, we can only predict exciting times ahead for FEM-Composites.

Another company that completes this list is Herding. The German company brings over 35 years in the production of filter media, dust collecting systems and filter systems for industrial use. They debuted in the AM industry 5 years ago, bringing new technological standard to metal AM.

“We have a simple but crucial role: clean the air in the system. We have been providing filter systems to various industries including pharmaceutical, chemical & laser but right now, the focus is on ensuring safety in handling reactive metallic powders and sustainability in peripheral processes; and this is something that Herding majors in”, Jörg-Armin Schulz, CSO/CMO at Herding, told 3D ADEPT Media.

Speaking of a tangible application of their products and services, the CMO mentioned a recent collaboration with Additive Industries. As part of this collaboration, they developed a tailored solution for the filtering process of the MetalFab1 system, the metal AM system of the Dutch manufacturer. Designed to fit into the confined space of the machine, the self-cleaning filter allows for the perfect filtering and safe extraction of process fumes from the building chambers.

What about the conferences?

Apart from exhibitors, keynote speakers also shared the latest technology developments in the industry.

Bioprinting was a key highlight in the conference. This technology is currently boosting R&D in regenerative medicine and will have a huge impact in the future. Of course, we are still very far away from the complete use of a 3D printed heart but researchers and companies like Black Drop Biodrucker GmbH are on the right track.

Furthermore, it felt good to see that speakers did not ignore what’s going on in the society. It was enriching to bring the topic of Coronavirus on the table and to talk about it with the goal of eradicating fear and looking for positive alternatives.

In that sense, Bart Van der Schueren, CTO at Materialise & Stefanie Brickwede, Managing Director at Mobility Goes Additive encouraged companies to take advantage of these tough times.

“You need pain to get things changed”, said Brickwede. Coronavirus deaths pass 6,500 worldwide. That’s why, now, more than ever, the industry must show resilience and to look for new ways to get rid of this situation. “That’s where AM comes into play”, continues Brickwede. “AM in the Dutch navy is born out of frustration and even in this situation, we have to look for new ways of leveraging AM.”

In this vein, one opportunity that arouses, lies in the type of market that AM enables. “AM is a glocalized market”, said Van der Schueren, talking about a market which is both global and local. “I understand the need for getting onsite, trying, seeing before purchasing but right now, this is not a viable alternative. The only viable and positive alternative is the ability to produce locally and on-demand, and that’s something AM is uniquely position to offer”, concludes the CTO of Materialise.

In a nutshell?

If it wasn’t the current pandemic, IPM AG would have gathered 1200 participants. Yet, they managed to gather about 600 participants at the conference, exhibitors, speakers & attendees combined. That’s a number nobody expected. For many companies such as 3D printer manufacturer RPS Ltd & 3D printing service provider 3Faktur that debuted on the show this year, these statistics would be considered as low but reality shows that AM Forum remains a real success as it gathers high quality visitors, which are not always seen in other AM conferences. One thing is certain, AMF Berlin is on the right track to become a European conference in the AM industry.

Image credit: IPM AG – Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com