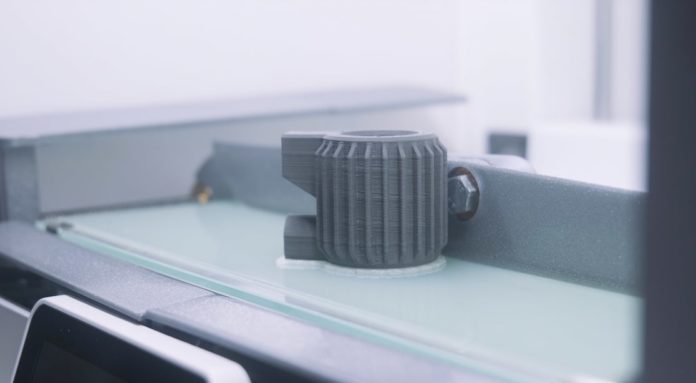

3DQue, an American company that is on a mission to automate 3D printing, has recently performed successful tests of Quinly automation for metal 3D printing.

While we discovered the company through its QPoD unit, it should be noted that they have developed Quinly to help manufacturers achieve mass production of finished goods, clear print backlogs, secure supply chains, or even tackle the issue of emergency parts and jigs and fixtures often required in manufacturing operations. To do so, Quinly, a virtual operator runs your desktop 3D printer 24/7. The company says it is completely hands-free, therefore is an ideal solution for schools and maker labs where printers are used by the public.

3DQue has recently performed some tests on Ultimaker S5. Results indicate automation decreases printer operator time 90%, lowers cost per part 63%, and reduces initial capital investment from $2.2M to $220,000 (90%) when compared to traditional metal 3D printing.

“Lower up-front and per-part costs combined with less operator time and higher throughput without having to incur the high risk of part stacking is a game changer for many manufacturers,” states Mateo, Co-Founder of 3DQue Systems, “Quinly allows companies to easily scale metal part production by automating their Ultimaker S5s they already have and are using for plastic parts.”

Three of the biggest challenges to scaling metal printing are the high labor, equipment, and operating costs. Based on current printing methods, for the metal prints market to reach even 1% market share ($20B) by 2025, companies would have to train more than 4 million skilled operators and spend $2T in equipment for printing. With Quinly automation, $20B in metal prints could be achieved with just 400,000 skilled operators, $300B in automated equipment, and parts would be less than 1⁄2 the cost of metal printed parts today.

“Shifting 3D printing from a batch process to a continuous-flow process, automating existing printers, and connecting production through digital supply chains allows companies to cost-effectively produce large volumes of parts in-house or onsite at customers. By reshoring production, companies have more flexibility, lower inventory, and secure their supply chain.”, said Stephanie Sharp, CEO of 3DQue Systems, “And they eliminate bulk shipping and warehousing, two of the major sources of GHGs, increasing sustainability while reducing costs. It’s a win-win.”

Summary results of automated metal testing

A. Capital Investment Reduced Over 90%

The Ultimaker S5 is a popular industrial 3D printer that uses fused filament fabrication (FFF) which is similar to Desktop Metal’s bound metal deposition system (BMD). Preliminary results from testing shows that Quinly the capital needed to start high volume printing drops 90%, decreasing initial investment from $60,000+ for a BMD printer to the $6,000 required to fully automate an Ultimaker for high volume metal printing.

B. Cost per Part Decreased 63% versus Bound Metal Deposition

3DQue printed a number of test parts using the Quinly automated Ultimaker S5. With Quinly, part costsdropped 63% compared to Desktop Metal’s BMD printing.

C. Costs 10x Less, Less Than Half the Floor Space versus Binder Jetting

Desktop Metal’s binder-jetting production system has a reported capacity of 63,230 parts per year (BMW water wheel). Tests showed that fourteen Quinly-automated Ultimakers would provide similar capacity, cost 10x less, could be housed in 30 square feet of shelving or placed close to end-users.

D. Increase Production Without Increasing Labor

Quinly eliminates manual tasks such as removing parts, applying adhesives, uploading files, and retting the printer. Tests showed that Quinly was able to scale production without adding more operators. In fact, operator time decreased over 90% and skilled technicians were able to spend time on optimizing prints to achieve even greater savings.

E. Competitive Part Strength & Material Properties

Metal FFF is a proven technology. Published results for sintered Ultrafuse 316L indicate tensile strength is roughly equivalent to solid steel in the X/Y direction, and is only 10% weaker in the Z direction. Post- sintering, parts are 98% solid.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com