As part of a partnership with EMS-GRILTECH, a Business Unit of EMS Group that specializes in the manufacturing of polyamides, AM company 3D Systems has developed a nylon copolymer called – DuraForm® PAx Natural.

Unlike other materials that are often designed for its proprietary technologies, 3D Systems gives the possibility for professionals who use third-party SLS 3D printers to process this nylon copolymer.

“We’re very excited to be able to collaborate with EMS-GRILTECH in a way that allows us to not only advance our innovation roadmap but also advance materials performance for the industry,” said Dr. Edwin Hortelano, senior vice president, materials engineering & development, 3D Systems. “With DuraForm PAx Natural, we’re not only bringing a superior product with leading mechanical properties, we’re also delivering a new material for use with any SLS printing technology, which we intend to expand to other powder-bed fusion platforms. This is our first step in opening 3D Systems’ materials portfolio to the entire industry which allows a broader pool of manufacturers to realize the benefits of this unmatched material. We look forward to introducing more PAx-based materials among others in the future.“

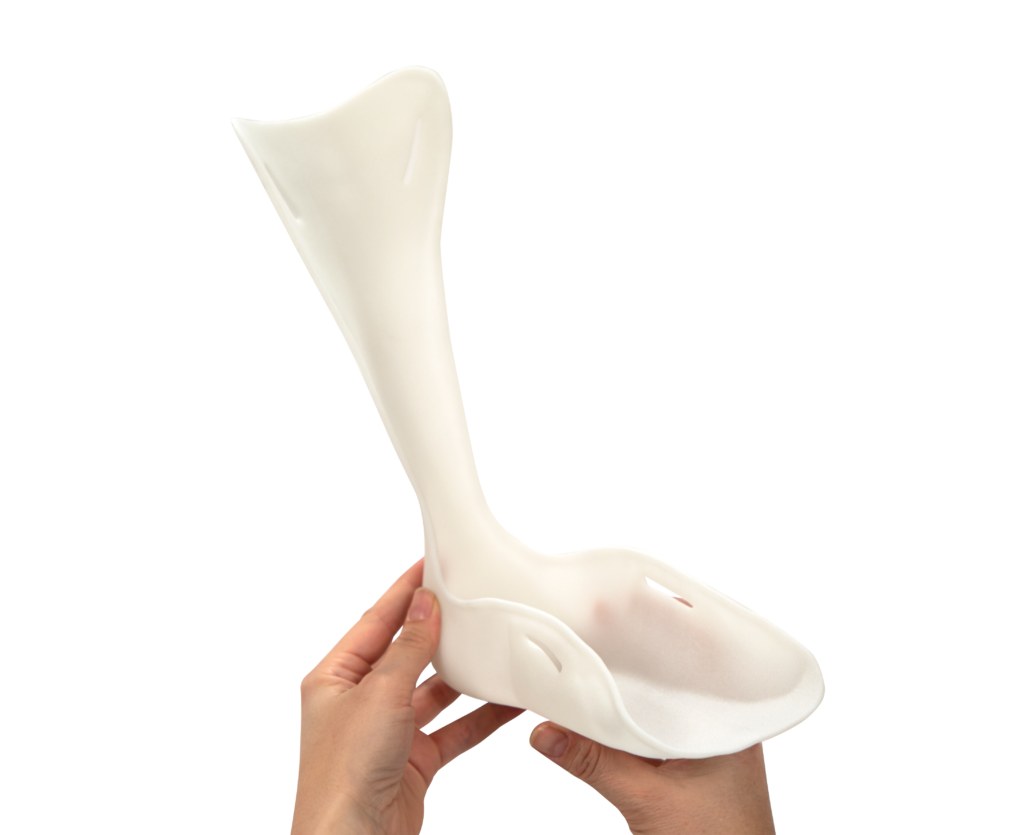

The material would integrate properties similar to injection molded plastics and features high impact resistance with high elongation at break in any direction. It can enable tough, lightweight, production-grade parts for applications such as orthotics, tooling handles, splints, and braces, ducting in rugged environments, living hinges, liquid reservoirs, and enclosures requiring high impact and high toughness.

As far as manufacturing is concerned, the material can be printed at a low temperature (i.e., 120°C) which facilitates efficiencies in both printing and post-processing. When compared to other nylon materials (i.e., PA-11 and PA-12), DuraForm PAx Natural enables significantly reduced time to parts-in-hand which not only helps service bureaus and manufacturers maintain their competitiveness but also helps accelerate supply chains, 3D Systems says.

The low printing temperature of this material enables high throughput, and its designation as a clean running material results in low operator maintenance. With the lower printing temperature, parts can be ready to ship the day after an order is received. Similar PA12-based parts will need another day before a part is ready to be shipped, the company continues.

DuraForm PAx Natural possesses very impressive long-term stability ratings of over five years indoor for mechanical properties and color. When parts are post-processed using vapor-honing, finished parts have excellent translucency and smooth finish which enhances the breadth of applications for which this material can be used. In addition, the vapor-honed DuraForm PAx Natural material moves the elongation at yield capability past that of PA-11 and PA-12 materials. This material also has high reuse rates (a 30% refresh rate is recommended) which helps reduce waste and decrease production costs.

Simon Maier, head of sales and marketing at EMS-GRILTECH, said, “The EMS Group is an established worldwide leader in high-performance polymers for injection molding and powder-based applications. EMS-GRILTECH has observed the powder bed fusion (PBF) additive manufacturing industry with keen interest over the last years, realizing that the technology is limited by the performance of the available materials. Thus, together with 3D Systems, we decided to use our expertise to develop materials that exhibit excellent performance in PBF systems and at the same time show technical properties that match those of injection molding. EMS-GRILTECH is excited about the capabilities of DuraForm PAx Natural and we’re looking forward to creating added value for the additive manufacturing industry with further material novelties in the future.”

3D Systems remains the exclusive distributor of this material.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com