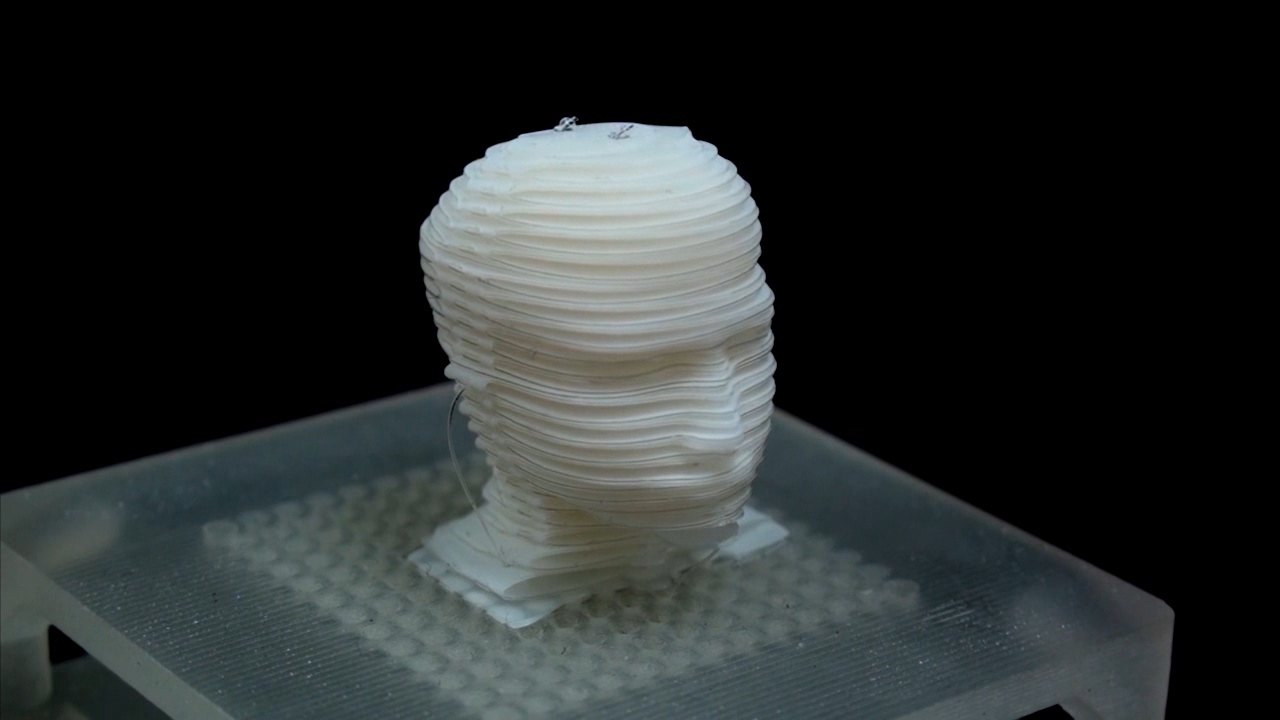

Dr. Sehyuk Yim in Korea Institute of Science and Technology (KIST) developed in collaboration with some researchers in US a technology that can manufacture 3D soft robots from plastic paper. The team designed geometric algorithms and realized the animation of the robots through audio-animatronics which integrate opera songs and movie monologues.

Soft robotics

Soft robotics is a field that increasingly raises the interest of scientists. Materials such as silicone, cloth, balloons, and paper are often exploited to improve the flexibility and adaptability of robots, therefore to enable smooth and natural movements.

An interesting advancement in the field that is currently gaining momentum is the RoboCup soccer world championships that highlighted the football game of autonomous robots with a human-like body.

Anyway, “when developing one robot, even experienced roboticists need at least several weeks for designing required mechanisms and robot structures and configuring a number of mechanical and electrical devices. Even though 3D printing technology has significantly reduced the manufacturing time and cost, all we still have to print dozens of individual parts, and then assemble them one-by-one. Above all, this is very expensive in cost. »

In order to simplify the process, Dr. Yim developed a new 3D fabrication mechanism: ‘additive self-folding’. Furthermore, they design process for the 2D fold pattern to connect all slices of the robot. Finally, smooth, natural and lifelike motion of the soft robots were implemented with the help of embedded tendons.

Dr. Yim stated that “This result is very impactful, because soft robotics now widens its application areas beyond wearable robots and/or medical robots to the art and culture technologies in which the film and entertainment industries are interested. Also, merging the soft animatronics with emerging artificial intelligence will bring forth a wide range of changes on personal robots as well as human-robot interaction field, we think.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});