With the goal of simplifying the way engineers use 4D Additive, CoreTechnologie has integrated a new feaure that would enable to repair STL files and scan data in a matter of seconds.

It’s been four years that the German-French software developer has introduced 4D Additive, a 3D printing softare that allows all 3D CAD formats to work together and share information in order to ensure the preparation of models and their production via AM.

Every year since then, each new version of the software ambitions to overcome the weaknesses of the previous one. In this specific case, the newly added feature – “Marching Cube” – will enable any type of triangulated 3D model to be automatically corrected and prepared for 3D printing.

The new feature should not be confused with the use of exact B-REP CAD data which provides the user the ability to generate repaired and optimized STEP models.

In this specific case, CoreTechnologie has taken into account the fact that data generated with a 3D scanner often leads to poor and non-repeatable STL files, which are not ideal for 3D printing, nor other subsquent processes.

To ensure error-free slicing and printing, it is necessary to repair errors on STL models and send closed solid models to the printer. In addition, scanned parts often have file sizes of several gigabytes due to the high number of very small triangles. Especially if several scanned files are to be printed in the same print job, the size of the data that must be sent to the machine can become a real problem, the software developer explains.

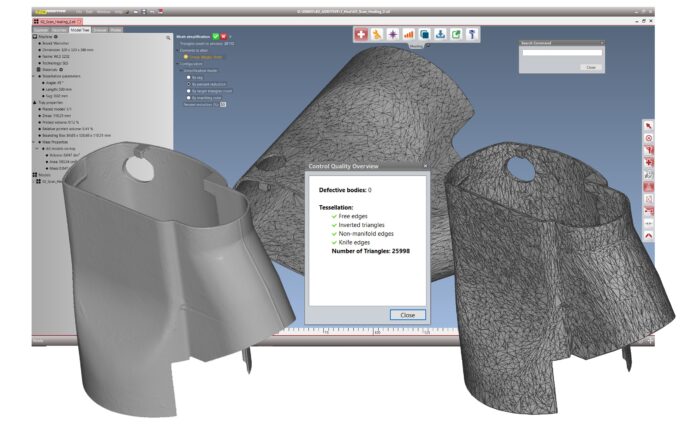

With the Marching Cube function, faulty STL models as well as scan data can be repaired and transformed into closed solids practically at the push of a button. The new function saves the user an extremely time-consuming manual repair. The Marching Cube function combines a “voxelisation” of the parts with their repair, whereby the size of the voxel, i.e. cube, and thus the fineness can be defined by the user. After the adaptive filling of the part volume with voxels, the so-called “voxilisation”, a closed 3D mesh is generated. The 4D_Additive software thus repairs models with hundreds and thousands of triangulation defects fully automatically within a few seconds, one can read.

Futhermore, with the latest version of 4D Additive, engineers also benefit from more possibilities when it comes to the intelligent reduction of triangles. Indeed, by defining a maximum angle between the triangles, the maximum chord deviation, by percentage reduction or by defining the desired number of triangles the file size and complexity of triangulated models can be reduced easily.

The use of the two new innovative functions makes it possible to repair any type of scanned part without manual effort, thus creating printable solids with a reasonable file size and resolution from scans and faulty STL models in a very short time. In the future, this technology will certainly enable a significant simplification of the scanning and printing process in many areas, CoreTechnologie concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com