Who has started shipment of its products? Who is working on the development of a new material? And who will distribute what? This edition of “news roundup” covers multiple milestones and 3D printing partnerships across the world.

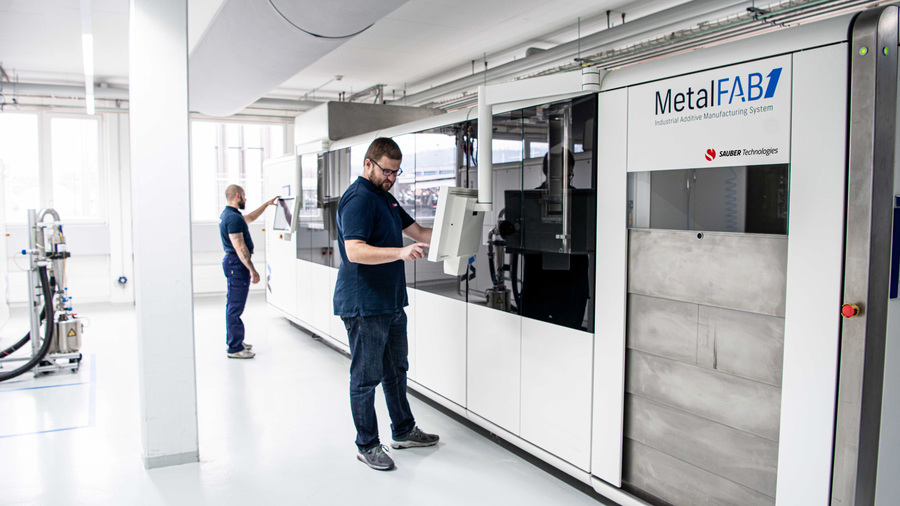

Sauber Technologies renews its partnership with Additive Industries

If you speak AM with any spokesperson at Sauber Technologies, you will know that Additive Industries’ MetalFAB platform has always been instrumental to the company’s technological developments in F1 and beyond. Both organizations have just renewed their partnership for three more years.

As you may have read in our March/April edition of 3D ADEPT Mag (pp 14-17), Sauber Group recently underwent a structural organization and created Sauber Technologies, a subsidiary that will leverage its F1 expertise and advanced technologies to deliver manufacturing services to other industries.

This summer, Sauber Technologies and Additive Industries will celebrate the fifth anniversary of their long-term strategic partnership: with the focus of both parties on productivity, part reproducibility and industrial series production, they are eager to keep pushing boundaries in metal AM to manufacture light-weight components for the automotive, industrial and tooling industries. From the start of the collaboration, Additive Industries has enabled the professionals of Sauber Technologies to accelerate in the metal additive manufacturing domain. The investment in the MetalFAB systems – with its unique open parameters – allowed Sauber to reduce cycle times in the manufacturing of innovative parts for its own wind tunnel models, Formula One race cars as well as third-party businesses, a press release reads.

SOLIDPRINT3D to distribute AM Solutions’ post-processing equipment in the UK

Machine manufacturer AM Solutions has announced SOLIDPRINT3D as the distributor of its M1 Basic machine in the United Kingdom.

As a reminder, the M1 basic is the versatile and compact machine that has recently been used by heliguyTM to optimize its 3D printed drone parts. The machine allows the simultaneous processing of multiple parts in separate chambers through the installation of divider plates, and the system features — among other things — Its comprehensive, easy to operate software package enables the storage of post-treatment processing programs that reduce the risk of operator errors. The machine promotes superior surface finish of work pieces in a cost-effective and repeatable fashion.

“We are proud to be able to add the AM Solutions M1 Basic machine to our portfolio, and truly recognise its ability to not only enhance the surface of metal and plastic 3D printed parts, but in many instances to improve part performance. It perfectly complements our existing range of post-processing equipment, and allows us to cater for the diverse set of requirements that users of AM have”, Neil Sewell, CEO at Solid Print3D notes.

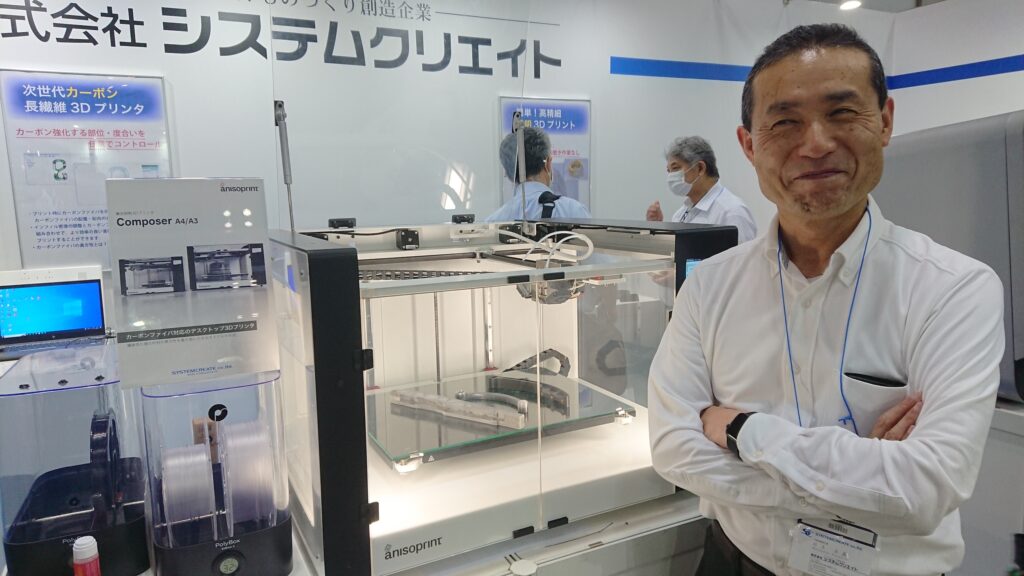

Anisoprint’s latest partnership marks first step in its expansion to Japan

In Japan, we witnessed another distribution agreement that will enable industrials to leverage 3D printed continuous fiber-reinforced composites. The exclusive partnership is signed between manufacturer of continuous fiber 3D printing systems Anisoprint and Systemcreate.

With recent deals signed in China and India, the Luxembourg-based deep-tech startup confirms the need for having reliable business partners across the world who understand the culture and speak the local language to ensure viable growth.

Systemcreate plans to invest more resources in marketing to promote the Composer systems and establish a team of engineers with in-depth understanding of the CFC 3D printing technology and provide outstanding customer support service, a press release reads.

“It is also my great pleasure that we can contribute and help Japanese engineers develop innovative products by using continuous carbon fiber 3D printers. We will now start collaborating closely with Anisoprint to accelerate cultivating the Japanese market”, Masayoshi Kawakami, President at Systemcreate notes.

Graphmatech and Wematter to develop electrically and thermally conductive powder for SLS 3D printing

3D printer manufacturer Wematter and graphene manufacturer Graphmatech are working together on the development of polymers that can be electrically and thermally conductive. The new material would decrease gas permeability, improve flame retardancy, and will be processed on the Gravity SLS 3D printer.

According to Wematter, aerospace and automotive manufacturers could use the material to print parts with lower weight and improved or maintained strength. The partners said this development will mark the first time that a powder based technology like SLS process graphene-embedded polyamide 11.

Shipment has started for Nexa3D’s XiP 3D desktop printer

Nexa3D, the developer of Lubricant Sublayer Photo-curing (LSPc®) technology, has started shipping its desktop XiP™ 3D printers to the US and Canada – with global availability opening soon through direct channels, as well as select reselling partners.

Since the launch of the 3D printer at Formnext 2021, the manufacturer said the product’s waitlist has extended to hundreds of product designers and creators looking to increase the throughput and efficiency of desktop 3D printing.

As a reminder, the machine features a large build volume (X: 195 mm, Y: 115 mm, Z: 210 mm), a 4.8 liter print volume and a 4K monochrome 9.3” LCD screen; it can deliver high-resolution and enable 50 µm / 100 µm / 200 µm layer thickness.

“The XiP desktop 3D printer is a truly exciting machine, and I’ve been excited to incorporate it into my company’s prototyping and rapid product manufacturing workflow,” said Rob Wiggins, Owner, Get It Done Dudes LLC. “The effort and attention to detail that the team at Nexa 3D have incorporated into the production of the XIP, along with its software and key features – speed, quality, and ease of use – are thrilling. I’ve used a lot of desktop 3D printers in my work before but there’s always been some piece missing, whether it be quality and materials to match speed or some kind of limitation in workflow. The XiP helped me gain ground in creating Hollywood-quality designs like nothing else. This system is something special, and I can’t wait to make more magic with it.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com