In order to exhibit the “Grande testone” (The Big Head), a large reproduction of Michelangelo’s David head, the artist Andrea Salvatori called for the help of WASP. The manufacturer made use of 3D Printing in ceramic to achieve the sculpture.

The large ceramic sculpture of David’s head

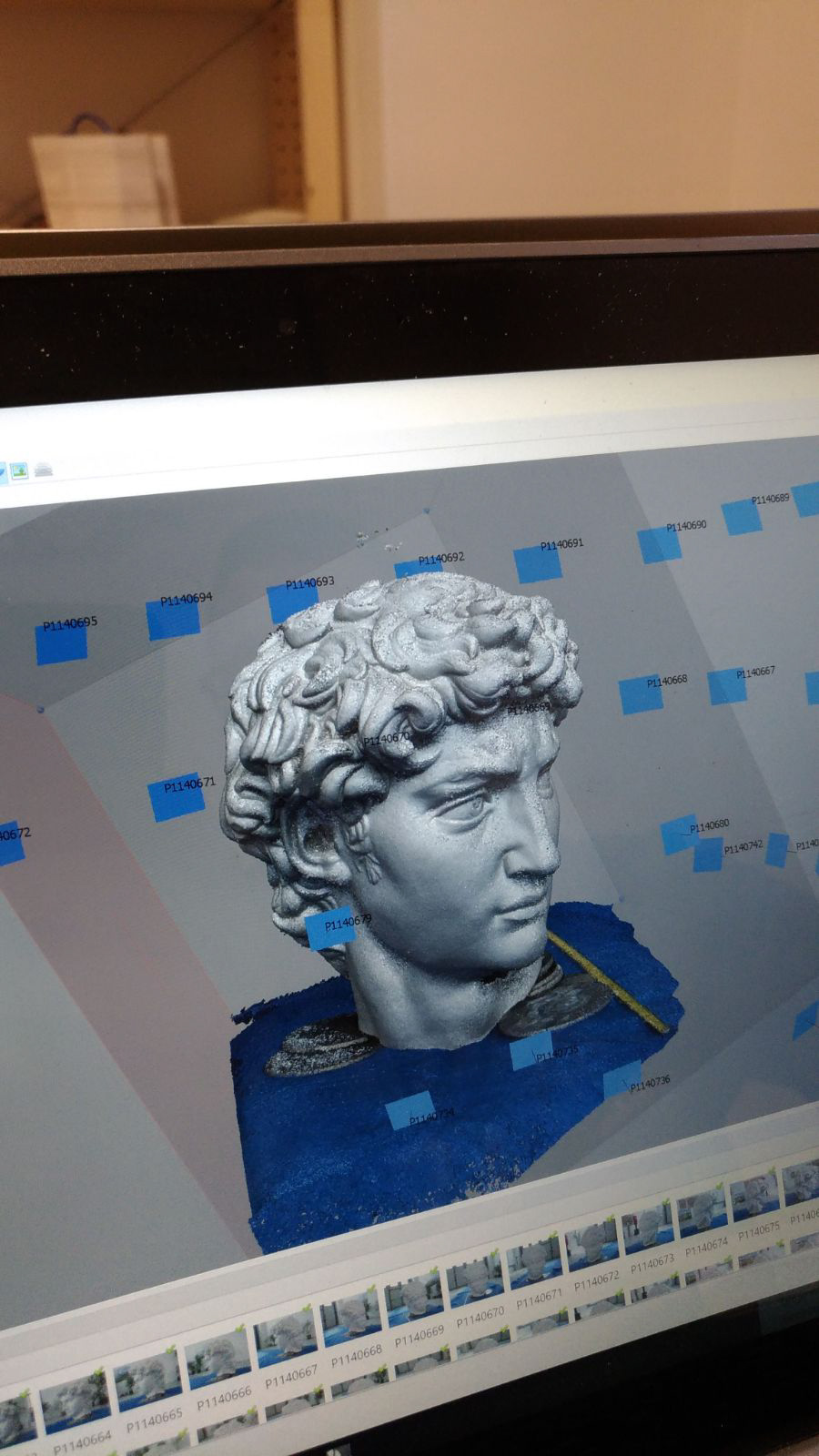

The sculpture was 3D scanned, 3D modeled before being 3D printed. The 3D scanner collected data of complex and detailed structures that enabled to faithfully and quickly reproduce the object. The file was graphically improved with the help of a 3D modeling software.

According to the team who worked on the project, 16 elements were divided and turned into molds for the hand molding of the ceramic sculpture. To these pieces a fixing system, necessary to recompose the figure in its entirety, was addeed.

Thereafter, they used one of the ceramic 3D printers of WASP, the DeltaWASP 3MT Industrial with pellet extruder, to 3D print the 16 elements. Plastic materials in granules were used for the printing. They are cheaper and more versatile for jobs of this size.

Lastly, the artist plastered the molds, obtaining an extremely complex forming process, in a short time and with a totally innovative method. Once obtained the casts for the realization of the sculpture, the artist has passed to the hand molding of the 16 components, immediately ready for the execution of the finished object.

From this type of shape, it was possible to obtain a number of copies, identical to the original model.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});