17-4 PH Stainless Steel is a precipitation hardening martensitic stainless steel that is typically seen in applications requiring high strength and a modest level of corrosion resistance. Described as a material with the highest tensile strength, its grades can have strengths which double that of types 304 and 316, the most commonly used stainless steels.

A team of researchers from the National Institute of Standards and Technology (NIST), the University of Wisconsin-Madison and Argonne National Laboratory have identified particular 17-4 steel compositions that, when printed, match the properties of the conventionally manufactured version. The new findings could help producers of 17-4 PH parts use 3D printing to cut costs and increase their manufacturing flexibility.

Despite its advantages over conventional manufacturing, 3D-printing of some materials can produce results that are too inconsistent for certain applications. Printing metal is particularly complex, in part because of how quickly temperatures shift during the process.

“When you think about additive manufacturing of metals, we are essentially welding millions of tiny, powdered particles into one piece with a high-powered source such as a laser, melting them into a liquid and cooling them into a solid,” said NIST physicist Fan Zhang, a study co-author. “But the cooling rate is high, sometimes higher than one million degrees Celsius per second, and this extreme nonequilibrium condition creates a set of extraordinary measurement challenges.”

Because the material heats and cools so hastily, the arrangement, or crystal structure, of the atoms within the material shifts rapidly and is difficult to pin down, Zhang said. Without understanding what is happening to the crystal structure of steel as it is printed, researchers have struggled for years to 3D print 17-4 PH, in which the crystal structure must be just right — a type called martensite — for the material to exhibit its highly sought-after properties.

So, what happens during the fast temperature changes?

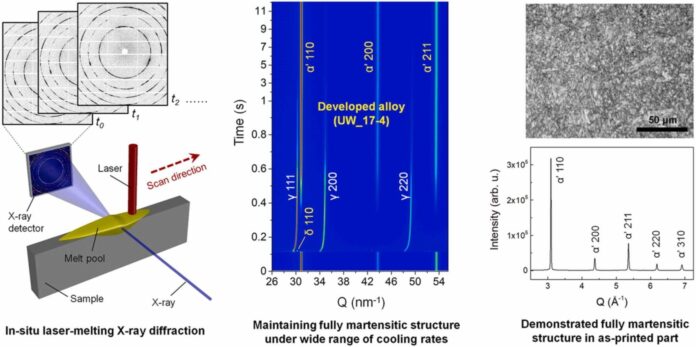

With the goal of finding a way to drive the internal structure toward martensite, the researchers leveraged a synchrotron X-ray diffraction, or XRD to observe rapid shifts in structure that occur in milliseconds.

The X-ray diffraction (XRD) end station measures constructive interference of the x-ray wave with repeating atomic and interfacial structure in materials. It is a foundational technique in materials science and engineering, providing information on regularly occurring and well defined structures such as crystal lattices or interfaces in multilayer materials.

“In XRD, X-rays interact with a material and will form a signal that is like a fingerprint corresponding to the material’s specific crystal structure,” said Lianyi Chen, a professor of mechanical engineering at UW-Madison and study co-author.

The team mapped out how the crystal structure changed over the course of a print, revealing how certain factors they had control over — such as the composition of the powdered metal — influenced the process throughout.

While iron is the primary component of 17-4 PH steel, the composition of the alloy can contain differing amounts of up to a dozen different chemical elements. The researchers, now equipped with a clear picture of the structural dynamics during printing as a guide, were able to fine-tune the makeup of the steel to find a set of compositions including just iron, nickel, copper, niobium and chromium that did the trick.

“Composition control is truly the key to 3D-printing alloys. By controlling the composition, we are able to control how it solidifies. We also showed that, over a wide range of cooling rates, say between 1,000 and 10 million degrees Celsius per second, our compositions consistently result in fully martensitic 17-4 PH steel,” Zhang said.

The new study could make a splash beyond 17-4 PH steel as well. Not only could the XRD-based approach be used to optimize other alloys for 3D printing, but the information it reveals could be useful for building and testing computer models meant to predict the quality of printed parts.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com