As part of its series of tests, the engineering department of 3D Adept carried out the test of the Stratomaker 3D printer of the French manufacturer Obro.

It is a 3D printer that integrates the Fused Deposition Modeling (FDM) additive manufacturing technology and offers advanced features for both professionals and 3D printing amateurs. Its printing dimensions are 225x205x220 mm.

Without further ado, 3D Adept’s opinion …

Unpacking

It must be said that this 3D printer associated with its packaging and its accessories has a total weight of 18Kg. Furthermore, the layout of the different components in the box enables the user to bring out the machine without the need for assistance.

Content of the packaging

The packaging included a range of tools required for operations before and after printing: a cleaning brush, two PLA bobbins, a power cable, adjusting wrenches and a user guide.

The packaging included a range of tools required for operations before and after printing: a cleaning brush, two PLA bobbins, a power cable, adjusting wrenches and a user guide.

The 3D printer itself consists of a removable tray, an intuitive touch screen of 5 inches with color display that enables to easily manage the settings and the printing on the one hand; on the other hand, a Wi-fi connection and an SD card reader for file transfer as well as an Ethernet port for a possible networking. The 3D printer also integrates a camera for real-time monitoring of the printing process from an Android or iOS computer or smartphone and an extruder with a 0.4mm nozzle.

Installation

Fifteen minutes after unpacking, we started the first 3D printing. It should be noted that the printer was completely assembled when we received it. In addition, the user guide provides further details about the settings and images describing the functioning of the machine. Furthermore, features such as automatic calibration enable the user to save time and to have a rapid control of the machine.

Software

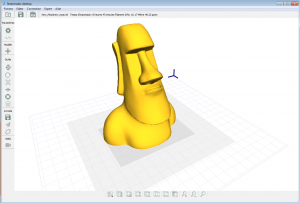

The Stratomaker printer works with StratoSoftware, an easy-to-use and intuitive software. It can be downloaded for free from the manufacturer’s website. The software allows the user to edit the 3D models and transfer the print file from the computer to the 3D printer using a Wi-Fi connection. The file transfer can be also done using the SD card provided with the accessories. However, once the 3D model is edited, it is converted to the “g.code“ file format (it is the file format recognized by this printer).Apart from the StratoSoftware, the user can make use of the mobile application Stratomobile (Android or iOS). Just as software, it enables the user to remotely control the printing.

The Stratomaker printer works with StratoSoftware, an easy-to-use and intuitive software. It can be downloaded for free from the manufacturer’s website. The software allows the user to edit the 3D models and transfer the print file from the computer to the 3D printer using a Wi-Fi connection. The file transfer can be also done using the SD card provided with the accessories. However, once the 3D model is edited, it is converted to the “g.code“ file format (it is the file format recognized by this printer).Apart from the StratoSoftware, the user can make use of the mobile application Stratomobile (Android or iOS). Just as software, it enables the user to remotely control the printing.

Printing

Printing

The touch screen of 5 inches facilitates navigation through the menus of the interface. It is therefore possible to adjust settings and presettings before printing (preheating, calibration, verification, etc.).

Once the machine was ready and calibrated, we introduced our 3D model in the software in order to edit it and convert it to the print format compatible with the printer.

In order to facilitate the removal of objects after printing, the manufacturer recommends the use of a glue on the tray.

The automated 3D printer manages the upgrade of the removable tray at each launch, ensuring accurate and consistent work. The print file being selected, the expected printing time is displayed on the touch screen of the machine.

Once the printing process has started, a LED light whose color changes according to the steps of the printing is activated, giving by this way an animation to the printing process.

Once the printing process has started, a LED light whose color changes according to the steps of the printing is activated, giving by this way an animation to the printing process.

As far as the sound is concerned, the Stratomaker 3D printer is less noisy than other printers of the same category and fits well in a workspace. As for the vast majority of printers using this manufacturing system, we recommend its use in a space dedicated to manufacturing, in order to keep people away from odours resulting from filament fusion.

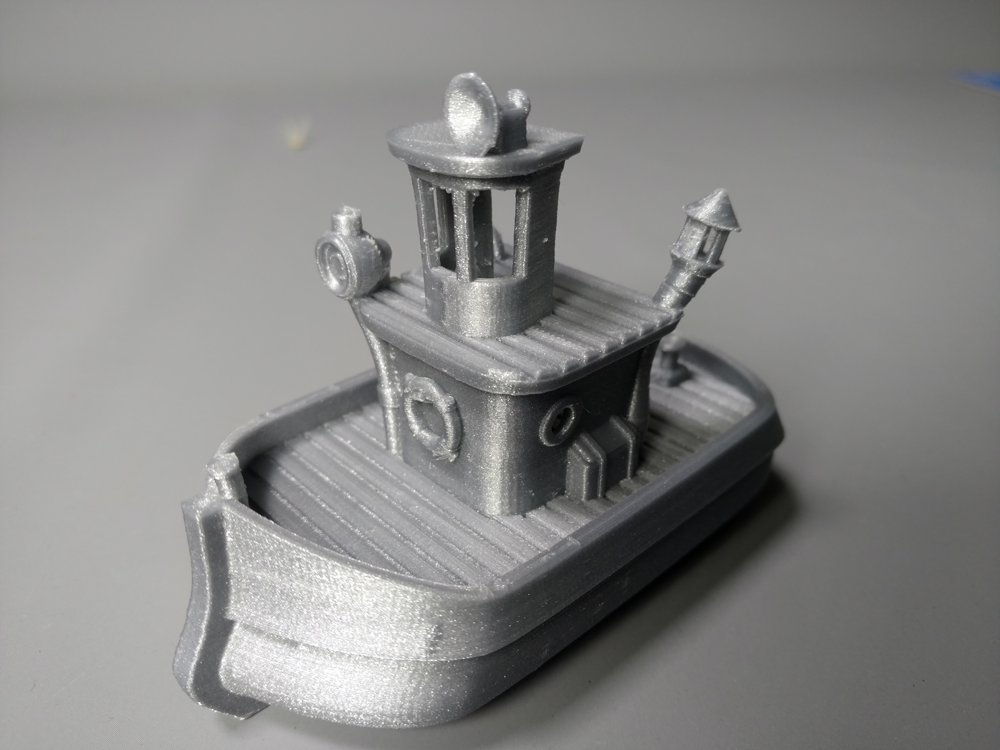

Printed objects

A review of the first printed objects gives an overview of the print quality of this machine. The following images illustrate the print quality of the printer:

Using the kit supplied in the accessories, we cleaned both the external and internal parts of the nozzle after printing.

As far as compatibility is concerned, this printer is compatible with PLA filaments (1.75 mm of diameter). An automatic charging and discharging device is integrated in the printer. The use of filaments from third-party companies also offers a range of possibilities for the printing.

The last word

In the end, we believe that the Stratomaker machine is a quality 3D printer, based on a simple, automated and intuitive use. Its design, its robust and rigid construction are its first main highlights.

We highly appreciated the ease of use of the machine due to the automation of certain operations. Thanks to the touch screen of the machine, it is possible to easily manage settings and presettings.

However, some points still need to be improved. Despite the automatic charging and discharging device, it is not very easy to insert the filament in its tube. Since we encountered some difficulties regarding these operations, we believe some improvements still need to be made in this regard.

Despite these difficulties, the test of this printer remains positive. The quality of the printed objects speaks for itself. In our opinion, the beginner who is looking for a 3D printer to begin his 3D printing journey or the expert who is looking for a machine to quickly prototype his technical parts (PLA) will not be disappointed. Thanks to its large print volume, this 3D printer distinguishes itself from other machines in the same range.

| STRENGTHS | AREAS FOR IMPROVEMENT |

|

|

Last, with all factors considered (ease of use, accessories, print quality, speed, software and applications), if we should give an overall rating for this printer, it would be 8/10.

Makers or professionals who are looking for performance could definitely be interested.

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});