AM can be used in bioprocessing to enhance efficiency, customization, and performance. Some of the applications include bioreactors and fluidic systems, filtration and separation systems, bioprinted organoids & disease models to name a few.

The Nexus project aims to develop specialized AM-compatible materials optimized for single-use bioprocessing applications.

Photocentric, Sartorius, Metamorphic, CPI, the University of Sheffield and Imperial College London – partners of this project will receive £1.9m of funding via the Innovate UK (IUK) to achieve this purpose. These companies bring together extensive expertise across advanced manufacturing automation, digital design and optimization, as well as material innovation and bioprocessing.

Single-Use Technologies (SUTs)

The project aspires to offer a greener alternative to SU bioreactors with enhanced circularity and end-of-life pathways, all while retaining the flexibility of disposable systems.

Single-Use Technologies (SUTs) offer numerous benefits, including faster setup and flexible process configurations, while significantly contributing to the reduction of resources like water, electricity, and caustic chemical usage. Although their waste contributes only about 0.002% to global plastic waste1, this project aims to further enhance the advantages of SUTs by introducing sustainable material formulations for additive manufacturing.

Paul Holt, Founder and Managing Director of Photocentric commented, “Through harnessing the advanced capabilities of our latest 3D Printing innovation, JENI, we’re really excited to be part of this important partnership and the development of a new generation of cost effective, sustainable solutions for biopharma.”

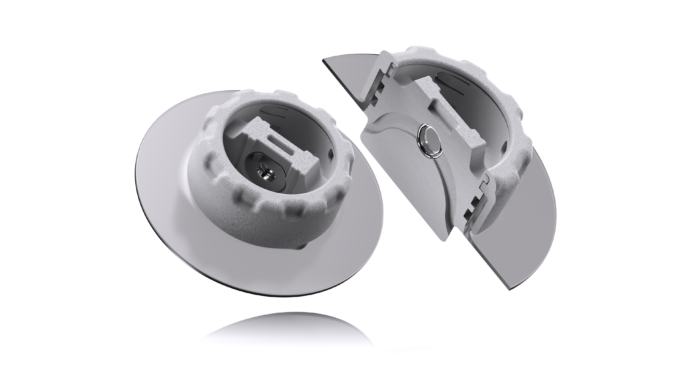

By utilizing advanced 3D printing technology and newly developed eco-friendly, bio-based resins to produce thermosets that can be autoclaved for reuse, Project Nexus aims to tackle current challenges and enhance sustainability through greater circularity – aligning with government targets for reducing waste and promoting sustainable manufacturing.

The bioreactors will be tested for pharmaceutical R&D and point-of-care manufacturing, with potential reuse in industrial biotechnology for green chemical production. In addition to this, the technical, economic, and environmental impact will be assessed, highlighting the benefits of AM technology in reducing waste and enhancing efficiency through material circularity and system flexibility.

Project Nexus is fully established and set to deliver over the next 24 months.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com