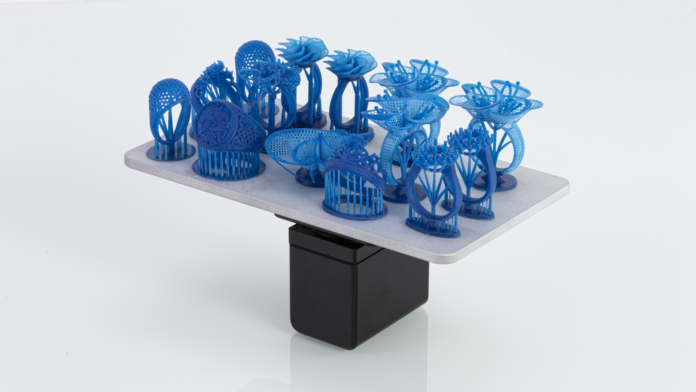

Zortrax has released today three new castable resins for jewelry applications. They are all included in the Z-SUITE slicing software which is now compatible with third-party LCD 3D Printers.

The launch of the new resins follows the launch of biocompatible resins for dentistry and prosthetics industries. Named, BlueCast Original, BlueCast X5, and BlueCast X10, they are equivalent to wax and can be processed the same way.

Just like the other resins, they can be printed on Zortrax Inkspire.

Main differences between the three resins

“BlueCast X5 is a resin designed for European style jewelry like engagement rings and stone settings. The material leaves no ash residue during burnout and contains no toxic compounds that could potentially contaminate the investment. Printed on the Inkspire, it offers smooth surfaces and high level of detail. BlueCast X5 does not require post-curing which speeds up the jewelry casting process even further. Apart from engagement rings, the material is recommended for medals and tools for stones presetting.

BlueCast X10 is intended for the American market where jewelry is usually more bulky and casted with larger amounts of metal. The resin works great in printing relatively large investment patterns used for signet rings and items casted with silver. BlueCast X10 is compatible with all kinds of investments and can be used for fast burnouts at 740 °C.

BlueCast Original is made for highly detailed, filigree designs typically encountered in the Middle-Eastern jewelry. The resin offers exceptional dimensional accuracy and quality of surfaces. After printing, it can be hand-shaped which is necessary for items with micro-pave settings or micro-incisions.”

For the first time, third-party LCD 3D printers could be used with the Z-Suite slicing software

Printing profiles for all three castable resins will be included in the Z-SUITE 2.11.0 release. The Polish manufacturer describes the software as easy to use It integrates all the desired functions expected by designers. Some of them include the “Rotation Optimization Tool”, “Raft-free 3D printing”, the ability to add cavities in the model, “Split functionality”, as well as an “Undo” feature.

Apart from integration and ease of use, it should be noted that Z-SUITE is updated on a regular basis.

A team of engineers is continuously working on how to improve its current functionalities and come up with the new ones.

All this makes Z-SUITE the most comprehensive slicing software on the market. And now everyone with an LCD 3D printer can use it. It is available for download as from today.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram ! Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com