Zmorph rebrands, launches new Zmorph Fab 3D printer & announces plans to release the Zmorph i500 industrial 3D printer in Q1, 2021

3D printer’s manufacturer Zmorph has undertaken a rebranding strategy to further target the industrial sector. So far, the Polish company has been committed to developing 3D printers for the professional market.

The rebranding strategy follows the financing round of 1.2 million USD secured by the manufacturer. For now, it includes the development of a new website that will reflect the evolution of Zmorph since its foundations in 2012. The company is shifting more towards a professional/industrial market segment, and the new branding reflects Zmorph’s core brand message: “3D printers that deliver”.

In 2020, the company acquired 3D Printers, owners of the HBOT brand. The HBOT team’s experience in the manufacture of industrial-grade 3D printers has been key to Zmorph’s move into the professional market segment, and expanding product portfolio with new 3D printers and solutions for modern manufacturing.

Bartosz Lanc, Zmorph’s CMO explains: “Today is the single most important moment for the Zmorph brand since 2012. We have evolved from a dynamic startup into a reliable brand and partner for professionals in over 120 countries. The rebranding will enable Zmorph to further expand into the global market, accomplish global growth objectives and strengthen our presence in the professional 3D printer market. Today, more than ever, Zmorph is becoming more competitive, and offering more capabilities to our customers and business partners.”

New Zmorph i500 planned for 2021

In Q1 2021, the company plans to launch Zmorph i500. This new workbench 3D printer for the professional and industrial markets includes a huge work area, single & dual extrusion 3D printing and a competitive quality-to-price ratio.

Zmorph believes that its new professional and industrial market offer will be a success, as the company combines the expertise of teams that have developed the HBOT F300, an industrial printer successful in Poland, and its workhorse Zmorph VX, now Zmorph Fab.

Zmorph and HBOT’s joint R&D team is working on the product which addresses professional expectations in terms of reliability, repeatability and reproducibility, as well as serviceability.

Zmorph is promising to deliver a full ecosystem. Alongside the machine, Zmorph has re-developed its slicer software and on-machine firmware. Zmorph is also in the process of acquiring a 3D filament manufacturer, to ensure even more predictable delivery from Zmorph i500.

Maciej Nawrocki, Zmorph’s CEO states: “We have had a very good year despite COVID. Our growth is strong, our strategy is solid, reliable, and backed up by investors who trust in us to make Zmorph a success.The 3D printing market is maturing, moving towards professional and industrial applications. Anticipating this direction, two years ago thanks to our smart marketing guys and customer-sensitive sales, we have created a product roadmap that addresses the trend. Next year, we will be launching new products to address this market.”

Zmorph is also working together with distributors and resellers to bring the new printer to the market in the first half of 2021. This will be a global launch where the new rebranding and marketing campaign will support partners in reaching end customers who are sure to benefit from the value that the new Zmorph i500 brings.

Zmorph has established partnerships with well-known distributors such as RS Components in Europe; Profound3D, Matterhackers in the US; 3D Criar in Brazil; 3D Prima, Hava3D, Maxwell, Beets 3D, Maha Chem in Asia; Torstar in Australia, and more. Altogether, there are 35 resellers worldwide.

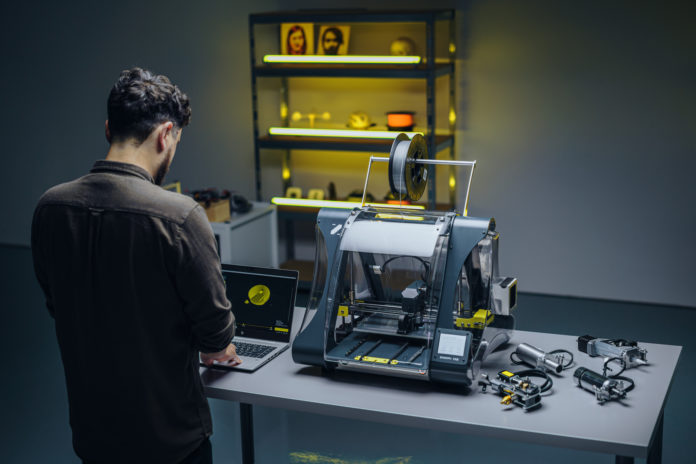

New Zmorph Fab, the Most Advanced and Easiest to Use, All-in-One 3D Printer

Today, the Polish manufacturer unveils the new Zmorph Fab – the most advanced and easy-to-use all-in-one desktop 3D printer, and a successor to the well-known versatile ZMorph VX. Zmorph Fab features an interchangeable toolhead system that allows 3D printing, CNC milling, and laser engraving and cutting with the same device.

Eliza Wróbel, Product Manager at Zmorph explains: “Zmorph Fab is made to be easy-to-use and reliable. The latter is crucial for a product that operates three different workflows and is meant to work 24/7. The new Zmorph Fab’s features are based on customers and business partners’ feedback making it the most advanced yet easy-to-use all-in-one 3D printer on the market. With new features like HEPA/Fumes Filter Zmorph Fab is a great addition to modern classrooms, FabLabs, workshops, and design labs.”

The Brand New 3D Printing Single Extruder Toolhead

The all-new Single Extruder Toolhead delivers faster prints with best quality. The new extruder gains motion sensors for filament detection. It’s now easier to feed the filament, and the machine will stop once it runs out of the material and wait for the user to feed the next spool of filament. The redesigned cooling fan improves the air flow, which allows faster overhangs 3D printing.

The Advanced CNC Environment

Zmorph Fab features an expanded CNC workflow. Starting from the new CNC worktable that was designed to allow easy and very stable material mounting (and is open for custom designs), to refurbished Voxelizer with CAM-standard workflow for CNC procedures with STEP operations, ability to change the tool within one G-code, and path visualisation.

The Safety Measures Air Filtration and Smart Toolheads

Due to the demand for educational standards and user safety, the new Zmorph Fab is equipped with HEPA/Carbon filtration system, which is optional for the users. The air filtration process makes it safer and cleaner to work with materials producing semi-toxic fumes and particles, such as ABS or fumes created during laser engraving.

Zmorph Fab detects which toolhead is installed with a SMART Toolheads System. Toolhead changing is now easier than ever before, which cuts down the time spent on workflow switching.

Last but not least, the new machine is equipped with industrial grade electronics, meaning that it is a desktop 3D printer, but with the heart of a professional industrial machine.

The New Voxelizer

To celebrate the release of Zmorph Fab, the company is also updating the slicing software. The new version of Voxelizer is ready for the refurbished CNC workflow, features more presets for 3D printing, and underwent rebranding to reflect the current brand image.

Technical specifications

Technology: FFF/FDM, CNC mill, laser engraver/cutter, thick paste syringe

Build volume: 250 x 235 x 165 mm (toolhead dependent)

Layer resolution: 0.05-0.4 mm (depending on the nozzle diameter)

Material diameter: 1.75, 3.00 mm

Nozzle diameter: 0.3 – 0.6 mm

Work area leveling method: automatic, manual

Connectivity: USB, Ethernet, SD card

Materials:

Maximum extruder temperature: 250° C

Maximum platform temperature: 115° C

Filter type: HEPA/Carbon

Software bundle: Voxelizer

Supported operating systems: Windows (7/10 64 bit) or macOS 10.13 or later

Full specification available at the manufacturer’s website.

Pricing

Zmorph Fab will be available in two bundles. The All-in-One set includes Single Extruder Toolhead 1.75, CNC Milling Toolhead and Laser Toolhead and costs 3999 USD/3599 Euros. The 3D Printer option is a cheaper variant for people and companies interested in the 3D printing toolhead only, and it costs 2959 USD/2659 Euros. There’s an extra option of making a custom set.

You can order Zmorph Fab via Zmorph online store or via one of the authorized resellers worldwide beginning today.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com