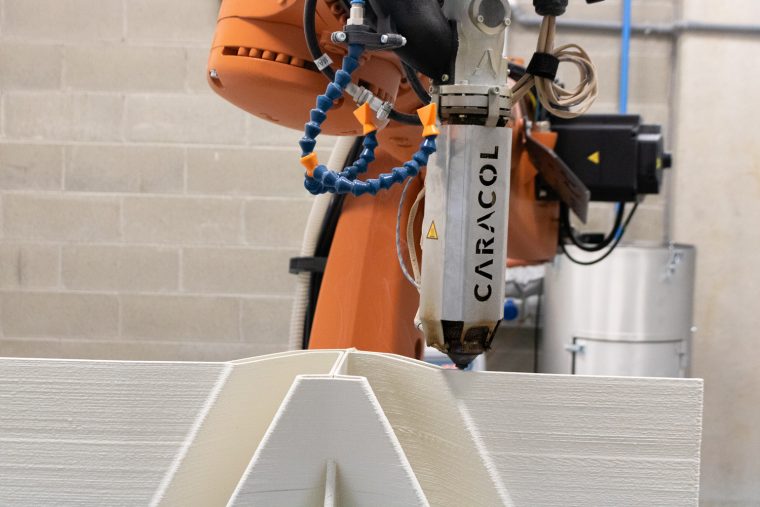

Large Format Additive Manufacturing is an ideal production candidate for marine applications. Very few applications have been shared to illustrate this argument until recently when large-scale machine manufacturer Caracol shared that Pershing, one of the seven brands of Ferretti Group, leveraged its AM technology to manufacture superstructures.

Using Heron AM in particular, the yacht manufacturer has been able to produce air grilles and visors above the windshield. AM helped the team achieve geometries with reduced weight and ensured high performance and reliability.

Designed for the Pershing GTX116, a sport yacht combining elegance, comfort space and the signature Pershing thrill.

Pershing GTX116 is a 35-metre yacht, with a sporty yet elegant style, and an extreme livability to elevate the seagoing experience to a new dimension. This sporty yacht optimizes all onboard weights to achieve high performance.

Yacht air grilles and other superstructures are traditionally produced through manual lamination of fiberglass on molds. This process requires multiple molds depending on the complexity of the geometry and involves intensive manual work by highly skilled labor, impacting both production time and costs.

In contrast, large-format 3D printing eliminates the need for master molds and tools entirely allowing a direct production process. With Heron AM, composite components featuring intricate geometries and highly customized designs can be produced directly from the digital model, bypassing the manual lamination phase. This significantly reduces prototyping and production times, enabling rapid iterations and design optimizations. Moreover, the process only requires finishing operations such as gel coat application, further cutting down on labor-intensive steps, a press release explains.

Caracol’s Heron 300 system is equipped with a High Accuracy (HA) extruder and a 3 mm nozzle. The grilles were printed using ASA reinforced with 20% glass fiber (GF)—a material chosen for its durability and resistance to harsh marine environments.

The 3D printing process took 72 hours to complete, producing an air grille measuring 4200 x 400 x 400 mm and weighing 40 kg. Compared to traditional manufacturing methods, this approach has resulted in substantial reductions in lead time (50%), material waste (60%), and overall weight (15%), making it a more sustainable and cost-effective solution.

The 3D printing process took 72 hours to complete, producing an air grille measuring 4200 x 400 x 400 mm and weighing 40 kg. Compared to traditional manufacturing methods, this approach has resulted in substantial reductions in lead time (50%), material waste (60%), and overall weight (15%), making it a more sustainable and cost-effective solution.

To ensure both weather resistance and a flawless aesthetic, the grille was finished with a gel coat, enhancing its durability against environmental exposure. The implementation of additive manufacturing for such large-scale yacht components showcases the potential of this technology to revolutionize production, offering greater flexibility and performance while significantly cutting down on inefficiencies.

In this specific project, the quality and flexibility of Caracol’s robotic platform have led to shorter lightweight air grilles production time, improved efficiency and reduced material waste, with a positive impact on both costs and the environment. Heron AM technology has proven to be not only a valuable ally in making lighter and stronger structural components, but also a catalyst for innovation, opening up new perspectives in the design and production of unique and highly customized yacht superstructures.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com