Ever since it has been acquired by BellandTechnology AG, 3D printer manufacturer Xioneer has remained in stealth mode. At the time, the company had just unveiled its flagship product, an industrial-grade 3D printer.

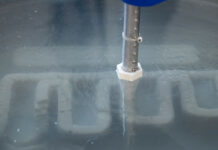

Fast forward to today: the company unveilsa support removal solution. Named Vortex EZ, the company said the device can easily fit in an office, workshop, lab, school, and production floor.

Suitable for all soluble support materials, the Vortex EZ features a very large 465 x 275 x 210 mm stainless-steel basket for desktop 3D printing post-processing today. This means that you’ll have a convenient and secure hold of your most delicate (and largest) parts, Xioneer says.

The plug-and-play operation requires five steps: add tap water and a few spoons of the company’s non-toxic VXL-EX washing powder – a non-caustic detergent developed to dissolve VXL -, place your 3D printed part with the support structure inside the basket, set dissolving temperature up to 85°C depending on the model material and support material you use, supports will now dissolve and it might take from a half-hour to a few hours depending on the complexity of the supports, rinse off any remains of the washing liquid with tap water.

“The Xioneer Vortex EZ can hold in its thermal stainless-steel tank up to 38 liters of tap water and is also suitable for solvents which are then agitated by a magnetically operated impeller that helps you dissolve the supports faster. It is as powerful as it is silent with a 1200 W heater”, a press communication from Xioneer reads. Here are the other key specifications of the support removal station:

| Technical features | Description |

| Outside Dimensions (WxHxD) | 640 x 435 x 370 mm |

| Basket Dimension / Maximum Part Size (WxHxD) | 450 x 200 x 250 mm |

| Net Weight Without Solvent | 22 kg |

| Adjustable Temperature Range | 30 °C – 85 °C |

| Heat-up Time (38L, 20°C – 70 °C) | Approx. 1 hour |

| Recommended Model Materials | No restrictions |

| Recommended Support Materials | VXL (All Types) |

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com