The new pills are tailor-made to each individual and can be produced on an industrial scale. Pharmaceutical companies have been looking for a way to produce pills on industrial scale. Apart from Xaar, Aprecia and Cycle are two other companies that are currently producing personalized medicines on an industrial scale, using 3D Printing technology.

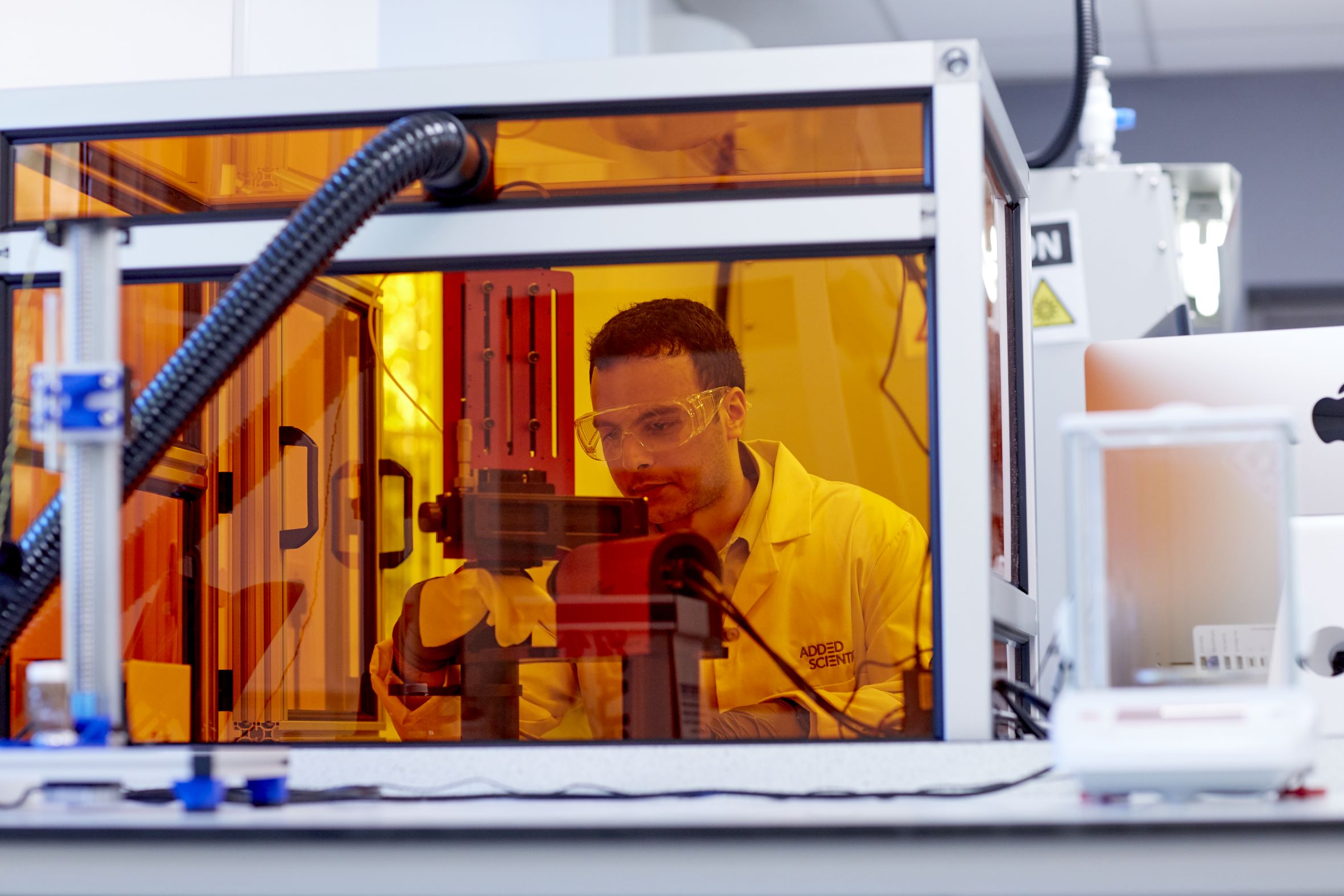

However, in this specific case, the challenge of the teams involved here (Added Scientific, Xaar and AstraZeneca) was to look at the long-term suitability of inkjet printing in dispensing APIs.

Craig Sturgess, Research Manager for Added Scientific thus explained: “Inkjet printing offers the ability to digitally control the printing with its precision placement of tiny droplets a few picolitres in size and the capability to place multiple materials to create complex multi-functional objects in 2D & 3D. Trial research carried out previously has shown that inkjet offers a real potential for printed medicines. This project was designed to answer questions pharmaceutical companies have around the suitability of inkjet printing in dispensing APIs at a scale that made both manufacturing and economic sense.” Craig Sturgess

The production of 1000 dosage forms as part of the first batches showed that the company saved a significant time in unit process times from inkjet printing when compared to traditional manufacturing methods.

“The Xaar 1201 is ideal for a wide range of industrial applications including Advanced Manufacturing due to its ability to print fluids with a range of viscosities, reactivity and conductivity,” says Mike Seal, Business Development Manager, Advanced Manufacturing, at Xaar. “This pilot project has demonstrated the Xaar 1201’s versatility for pharmaceuticals and how inkjet printing is proving itself to have the potential to drive innovation as well as efficiencies in many areas of 21st century life.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com