The market was not ready for multi-material 3D printing, so they came up with something better.

How many times did you find yourself attracted to a dish before you have even taken a bite? Most companies that have made 3D Food Printing their core business have focused their selling point on the power of aesthetics.

From 3D printed chocolate to 3D printed cocktail bitters, people are mostly looking at food 3D printing as a means to achieve an aesthetic purpose but the technology may have a much bigger impact. We caught up with one of the few companies that has made food 3D printing its core business to discuss this topic: byFlow.

Interestingly, the story of byFlow did not start with the goal of developing a complete offering around 3D food printing. It started with Floris Hoff, a technology enthusiast that was encouraged by his family – his dad, especially – to develop his 3D printers. At the time, studies were not advanced enough for him to have a better understanding of the technology. He was therefore learning from scratch how to develop 3D printers that could process multiple materials including silicone and ceramics to name a few – Due to the expensive cost of these materials, Floris Hoff used to run tests of his prototypes with Nutella (brand of chocolate paste). Following the advice of his dad to print other things than just silicone and ceramics, he decided to try food. In 2015, when the company was founded, the first idea was to provide the public with a wide range of 3D printing possibilities.

-

Founders Nina (right) & Floris Hoff

“We have launched the company in a very special way, in a pop-up restaurant, where we showcased all products our 3D printers were capable to print: chairs in plastics, plate in ceramics, etc. and we collaborated with a chef to bring the food. We realized that nobody was interested in multi-material 3D printing because they did not understand the concept of having one 3D printer for all those materials but they were interested a lot in food printing because it was something totally new”, Nina Hoff, Floris Hoff’s sister, co-founder and CEO of byFlow recalls.

Several launches thereafter in the pop-up restaurant confirmed the increasing interest in 3D food printing and the need to focus on a niche market. byFlow was taking off with their Focus 3D Food printer as flagship product. Today, the family business has developed a complete offering dedicated to the food industry: a collection of recipes, different applications, as well as the byFlow studio, a platform that makes it easier for chefs that “do not always have the technical background to design 3D models, to create 3D models. “To do so, they just upload an image that the software transforms into a 3D model, repairs it before printing.”

-

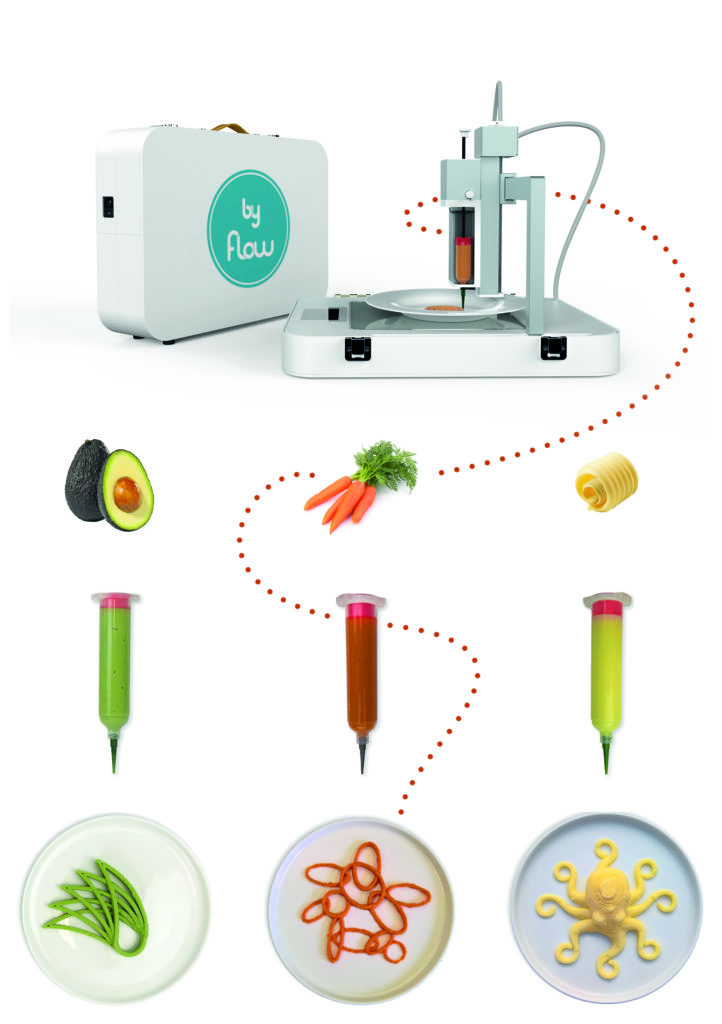

Focus 3D Food Printer -

3D Food Printing – ingredients explained

Different purposes of 3D food printing

Like a number of companies that specialize in 3D food printing, byFlow’s offering first attracted those who were interested in making creative aesthetics looks. Thereafter, in addition to restaurants, and bakery, their database of customers grows to reach primary schools, high schools and universities.

“At first, we were very focused on the aesthetics of food and the benefits one can have when personalizing food without moulds. Chefs really benefit from it because they no longer had to use moulds. Over time, we realized that the potential for food 3D printing could go beyond aesthetics and could benefit several industries”, our guest in this Opinion of the Week states.

Indeed, primary schools will leverage 3D food printing to create some funny activities around food, high schools would be interested in learning 3D modelling and healthy food, while universities would focus on research. And that’s not all.

Medical professionals are increasingly interested in using food 3D printing as a solution that will help people suffering from swallowing disorders (dysphagia). As a matter of fact, byFlow collaborated with a Dutch university to explore how their 3D printers can help address this issue.

Hoff also reveals that, “2016 came with a big trend around personalized nutrition, food based on one’s DNA”. That’s an area where they are working right now and where we might see the impact of 3D food printers. In this vein, 3D food printers could be utilized to print snacks for instance.

This idea of personalized nutrition can go even further if we look at it from an industrialization perspective.

“R&Ds in the food industry can use our printers to create new food, not only for aesthetics purpose but also to apply different textures and tastes to food, which remains a very important aspect of one’s eating experience. At an industrial level, we have seen companies install print farms in their facility to print food products like chocolate at a large scale. We are currently investigating the potential of having multiple 3D printers connected to each other to scale production”, Hoff adds.

However, exploring the use of 3D food printers at an industrial level made the team at byFlow realize they have to do something about the large amount of food that is wasted every day in the industry. Such waste also has a severe impact on climate change.

“To address this issue, 3D food printers can be used to produce locally with ingredients that otherwise would have been thrown away. This means that you could get snacks whenever you need them instead of producing very large quantities”, the CEO explains.

According to Hoff, one common thread in these different purposes is that 3D food printing gives a more transparent way to people to know what they eat and perhaps, what’s inside their food.

Today, she envisions a future where chocolate 3D printing will conquer the market of this niche segment, as it is less “artificial” and more appealing. Speaking of byFlow, in the long term, the company’s “patented technology will enable personalized nutrition – probably at a medium and local scale, and we will have the “Thingiverse” of 3D models dedicated to food”, she notes. “In the future of 3D food printing, people will have a ‘food passport’ that will change and evolve based on them, their data and there will be a machine that can create the perfect food for them, taking into account their diet, potential diseases they may have and other nutritional values”, she concludes. But, we are not there yet.