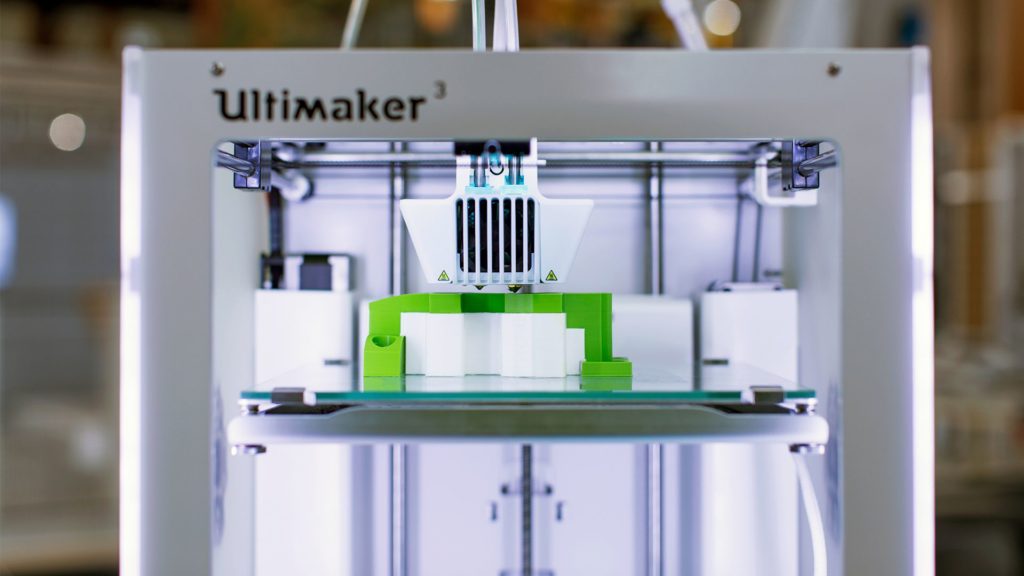

One of the acknowledged manufacturers of professional 3D printers announces the availability of Ultimaker Breakaway and a 0.25 mm print core.

Ultimaker Breakaway

Ultimaker Breakaway is a new support material for multi-extrusion 3D printing. Indeed, by using this material, the user will not need further post-processing to give a smooth finish to his/her 3D print. Furthermore, it can be quickly removed from the machine.

The manufacturer enables users to easily work with Ultimaker ABS, PLA, Nylon, CPE, and CPE+ with the release of Breakaway support.

Among the main benefits one can mention, it is important to notice that there is no sanding or waiting for the user’s support material to dissolve like there is with some alternatives. Furthermore if the use is ideal with build materials that could be sensitive to water, there is longer shelf life and less moisture sensitive compared to water-soluble support material, such as PVA.

0.25 print core

This newly created feature will enable the user to print highly detailed and thin-walled objects on the Ultimaker 3.

Offered in type AA, it is intended for use with Ultimaker PLA, ABS, CPE, Nylon and PP materials.

Furthermore, its use is recommended for a number of applications such as fine aesthetic detailed parts, and tolerance fit parts (bolts and nuts for instance).

Paul Heiden, Senior Vice President Product Management: “We found that our users were also in need of a support material that takes less time to remove. With Ultimaker Breakaway they can seriously speed up post processing and use their newly printed objects right away. We also followed up on the desire for highly detailed prints by developing a print core with a smaller nozzle size.”

Paul Heiden, Senior Vice President Product Management: “We found that our users were also in need of a support material that takes less time to remove. With Ultimaker Breakaway they can seriously speed up post processing and use their newly printed objects right away. We also followed up on the desire for highly detailed prints by developing a print core with a smaller nozzle size.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});