ULT AG, a company that specializes in extraction, filtration, and air-drying technology, has developed a new solution for effective and flexible process gas cleaning as well as concepts for dust collection in post-processing. ULT offers an extensive portfolio of ventilation solutions, some of which have been specially designed for applications in additive manufacturing.

Named AFM 200, the fourth-generation gas cleaning system was developed using ULT’s know-how in the field of additive manufacturing. A know-how that we have been able to discover through various conversations with the company. Over time, ULT has been able to advise and demonstrate why “air treatment is to production environment what materials are to 3D Printers”, or what air technology solutions works best for AM companies.

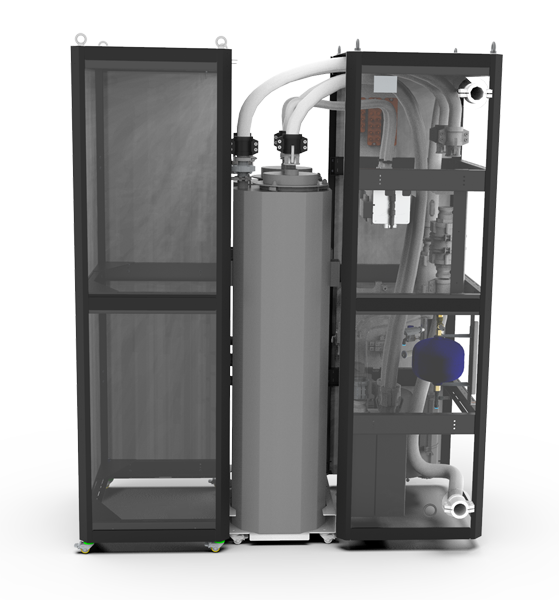

The newly created device requires a small installation space and is based on a modular concept that can be adapted to almost all technical requirements in metal 3D printing (LPBF – laser powder bed fusion), providing scalable air volumes. It is easy to operate, space-saving, safe and reliable. It is based on sophisticated ULT technology that is continuously being further developed.

A significant user benefit of the AFM 200 is contamination-free filter and powder handling, i.e., employees never come into contact with powders or condensates. Optionally, the system comes along with a newly developed system control and, hence, enables a quick connection to LPBF 3D printers (laser melting process).

In addition, the company will exhibit solutions for efficient dust and particle extraction during post-processing. Particular attention is paid to the efficient collection of all airborne pollutants, among others finest dusts, that arise during the post-processing of additively manufactured products.

In Hall 11, stand B18, visitors at Formnext could learn more about the use of air-drying systems – for example for powder storage, powder handling or the entire process environment.

Remember, you can post your job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com