Software company Ulendo Technologies has announced the integration of its add-in laser path optimization software into Dyndrite LPBF Pro.

Dyndrite LPBF Pro is an application developed by Dyndrite, that helps Laser Powder Bed Fusion (LPBF) printers deliver ideal printing capabilities, accelerated build rates, and cost savings.

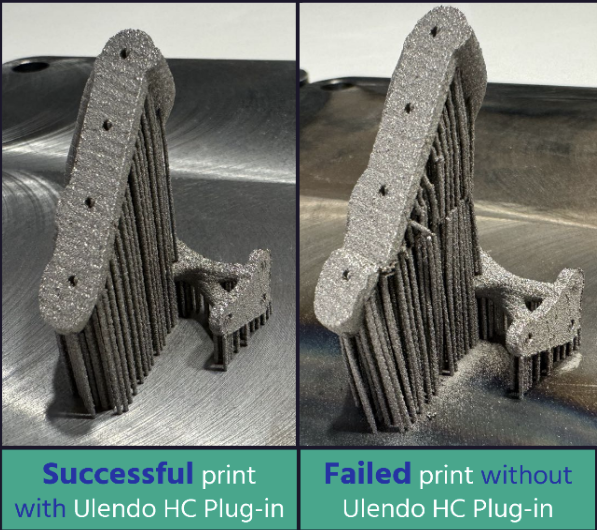

The add-in, named Ulendo HC (heat compensation), has been developed using Dyndrite LPBF Pro’s extensive list of APIs. Relying on research from the University of Michigan, Ulendo HC optimizes the LPBF printer’s laser path to reduce mean deformation by 50% and residual stress by 88%.

The new capability eliminates the expensive trial & error methods traditionally required for developing scan strategies and frees critical time and material costs for manufacturers.

Dyndrite CEO Harshil Goel depicts, “Our goal is to enable customers to print new materials with faster & enhanced features like thin walls, print without supports and improve surface finish. Our tools can be combined with tools, like the one Ulendo can accelerate this goal. We welcome Ulendo as the first company to provide add-in software to the Dyndrite LPBF Pro platform. With the addition of Ulendo HC to the platform, we are working toward our collaborative vision of Dyndrite LPBF Pro as a powerful metal 3D printing engine into which innovative companies like Ulendo can integrate their software add-ins and features..”

LPBF users can improve the quality of parts and production reliability from scan strategies without requiring additional inputs or steps using the software. “When working with high-cost materials or large, complex builds, even one failed build can significantly impact the bottom line. Ulendo HC aims to eliminate these issues, improving the profitability and reliability of LPBF as a production tool” reveals Ulendo CEO Brenda Jones.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.