A newly approved patent, titled “Development of Bio-Composite Materials for 3D Printing Using Milk Proteins,” has opened the door for spoiled milk to reduce the environmental footprint of 3D printing materials—and pour milk money into the pockets of Wisconsin dairy farmers.

A three-pronged approach

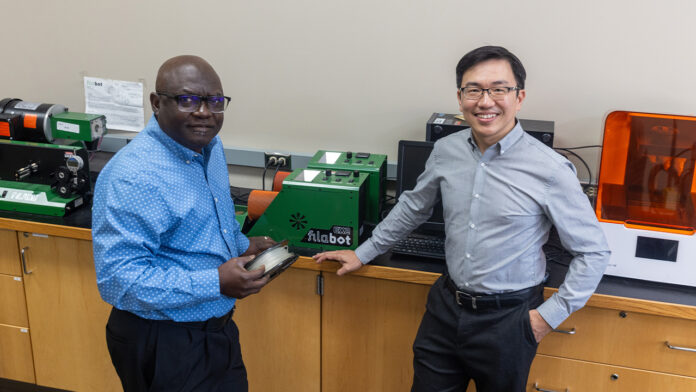

Dr. Joseph Wu, associate professor of chemistry and Dr. John Obielodan, professor and chair of the Department of Mechanical and Industrial Engineering, from the University of Winsconsin led the project. They aimed to:

- Reduce economic waste

- Address the fact that petroleum-based plastics are non-biodegradable and pose environmental and health hazards

- Explore the potential to use casein and whey from spoiled dairy products to make plastic materials.

Repurposing proteins from dairy waste into useful products could reduce dependency on petroleum-derived polymers. An added benefit is that it could provide a new revenue stream for dairy farmers, positively impacting rural communities in Wisconsin.

The inspiration behind the research came during the early days of the COVID-19 pandemic, when supply chain disruptions led to significant dumping of milk across the country.

“We knew dairy products contain proteins like casein and whey,” observed Obielodan, professor and chair of the Department of Mechanical and Industrial Engineering. “We asked ourselves, ‘Why can’t this milk, instead of being wasted, be turned into something valuable?’”

That simple question sparked a five-year journey of experimentation, development and persistence. The effort culminated in WiSys being awarded a U.S. patent for a novel method of transforming dairy waste into usable plastic—a breakthrough with global significance as the widespread use of non-biodegradable, petroleum-based plastics remains a major concern.

Challenges along the way

The biggest challenge was determining what form of protein would better serve the intended purpose.

“We needed to figure out what kind of protein, and in what form, would yield the best results,” Obielodan explained. “We started by creating our own proteins, then tested some commercially available ones before finding the one that gave the best results. These proteins were used with existing 3D printing materials.”

Figuring out the right mix of ingredients for the polymer was another important part of the study, since the amounts used affect how strong and flexible it turns out. This meant some adjustments had to be made to get the best results. UW-Plattville students also got a firsthand look at how this advancement in 3D printing evolved.

“We involved students and hired them to help set up the experiment,” said Wu. “They had to break the protein down and try to purify it. We included both chemistry and mechanical engineering students.”

The next step?

This project is a powerful example of circular economy thinking. By reusing what would otherwise be food waste, the innovation reduces the environmental footprint of 3D printing materials while also lowering costs for manufacturers and hobbyists alike.

The next step would involve further development of the technology and the transfer of intellectual property to industry partners for commercialization.

“Looking ahead, a variety of products could be made using proteins derived from milk,” declared Obielodan. “From 3D printing filaments to other engineered materials, the possibilities are wide-ranging.”

By taking a waste product and converting it into a useful, eco-friendly material, the invention checks every box: sustainable, innovative and socially impactful. So, next time you pour a glass of milk or slice some cheese, remember that the product might one day help print your next phone case, a part for a car, or even a custom medical device.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com