OEM TRUMPF has qualified 6K Additive’s titanium metal powder for use in the TruPrint additive manufacturing systems.

Acknowledged for producing AM powder made from highly sustainable sources, 6K Additive provides a full suite of metal and alloy powders, including nickel, titanium, copper, stainless steel, and refractory metals such as tungsten, niobium, and rhenium.

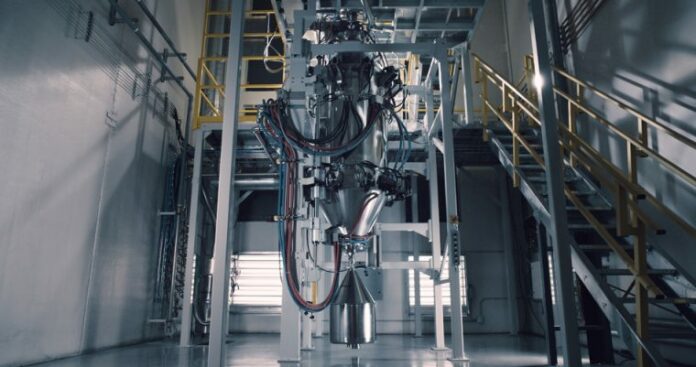

At the heart of its process lies the UniMelt® production-scale microwave plasma system, a technology that spheroidizes metal powders while controlling the chemistry and porosity of the final product with zero contamination and high throughput. According to a recent LCA, this approach makes it possible to achieve reductions in energy usage and carbon emissions of 90% for its nickel-based alloys and a 75% reduction in titanium alloys.

“At TRUMPF, we are dedicated to making our customer’s experience with our TruPrint systems deliver the highest level of performance and this includes the powder they use for their metal parts,” said Dennis Pede, Material engineer and scientist at TRUMPF. “TruPrint systems are open systems, allowing our customers to use the powder of their choice. However, for optimal process conditions and material properties, we recommend suitable material powders and work closely with our partners. Additionally, more and more our customers are asking us for metrics on the environmental footprint of our machines and the process. Having 6K Additive’s titanium sustainable powder added as an approved qualified powder, ensures customers get the quality assurance with the added value of driving down their CO2 footprint.”

This qualification will expand the use of titanium in aerospace applications and reassure customers that printed parts will meet their most stringent requirements and will have the lowest environmental impact.

Looking for a job in the AM industry or hiring new talent? You can post job opportunities on 3D ADEPT Media for free or explore openings via our job board. Stay connected by following us on Facebook, Twitter, LinkedIn & Instagram, and subscribe to our weekly newsletter for the latest updates. Have a story to share or want to be featured in our next digital magazine issue? Send it to editor@3dadept.com !