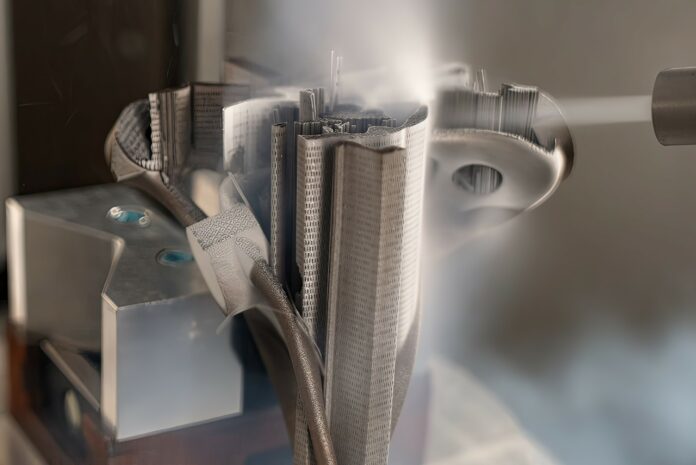

Engineering company toolcraft AG has developed a dry ice blasting solution to remove support structures from metal 3D printed parts. The announcement follows its recent collaboration with Siemens Digital Industries to propel porous metal structures in industrial applications.

Dry-ice blasting is similar to other forms of media blasting such as sand blasting, plastic bead blasting, or soda blasting in that it cleans surfaces using a medium accelerated in a pressurized air stream, but dry-ice blasting uses dry ice as the blasting medium. This technique is nonabrasive, non-conductive, nonflammable, and non-toxic.

Used in-house for its production projects, toolcraft’s dry-ice blasting solution is named SupportBlaster 320-HA. It is semi-automated and improves the ergonomic working conditions.

Industrials often rely on conventional methods, such as using a hammer and chisel. However, they are not just time-consuming and physically demanding, but also increase the risk of damaging the component.

In this specific case, toolcraft explains its machine can reduce the machining time per component by up to 80% – and sometimes even more, depending on the component and the specific requirements. All while prioritizing process reliability, high quality and the health and safety of employees.

“Companies that continue to rely on traditional, manual processes are going to find themselves under pressure in the future. The market is increasingly demanding automated solutions supported by technology”, says Christoph Hauck, Chief Technology and Sales Officer at toolcraft AG.

He believes that the combination of additive manufacturing and modern finishing techniques are an important competitive advantage, particularly in high-tech sectors such as aerospace and semiconductor industries.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com