3D Hybrid Solutions Inc. and Multiax join forces to offer the world’s largest 3D metal printer to RAPID + TCT on May 9th, 2017.

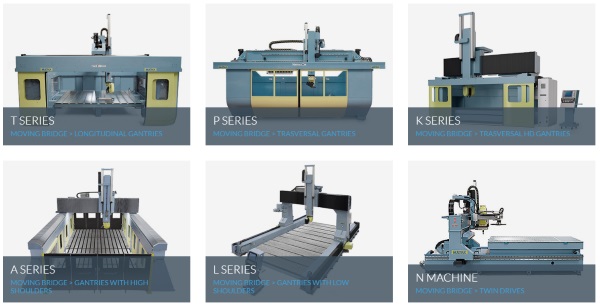

Through this collaboration with Multiax, CNC machines’ distributor and leader in the application of technology in the aerospace industry, the supplier of metal printing tools for CNC machines intends to offer a printable and mechanical space of more than 500 cubic meters.

With a speed of more than 20 pounds per hour, the addition of a metallic printing tool to a CNC machine takes into account the pre-existing need of post machining. However, machined internal features, 5 axis printing and only printing what is required are added values of this solution.

Hybrid manufacturing is the future for medium to large-scale metal additive manufacturing,” said Karl Hranka, founder, 3D Hybrid Solutions. “The infrastructure costs and paired value makes hybrid the obvious answer.”

Thanks to 5-axis printing, the need for support disappears and leaves room for almost unlimited design freedom.

Hranka also speaks of “material property freedom. Some of humanity’s greatest engineering feats are now happening because hybrid has the ability to economically furnish parts made with blends of dissimilar metals and composites.”

The main target of this hybrid solution is the market of large-scale metal additive manufacturing as unique supplier.