If we had to establish a list of unsexy topics in Additive Manufacturing, we would probably include beam profilers yet their role is important to deliver part quality.

A beam profiler (beam analyzer, mode profiler) is a diagnostic device for laser beam characterization. It helps to measure the optical intensity profile of a laser beam, i.e., the beam radius and the detailed shape.

While the use of such devices is well known in advanced laser manufacturing, particularly in semiconductor, display manufacturing, medical systems, defense, and industrial applications, a beam-profiler can also be used in Additive Manufacturing.

In laser-based processes, for instance, it helps to measure and optimize the quality of the laser beam. This is crucial in processes like Selective Laser Sintering (SLS), Selective Laser Melting (SLM), and Directed Energy Deposition (DED), where precise laser control directly impacts part quality.

In AM, we have identified 4 key benefits a beam profiler delivers: enhanced print accuracy by ensuring consistent beam quality, reduced defects like warping, porosity, or weak bonds, increased repeatability in production by maintaining stable laser parameters as well as extended equipment lifespan by preventing misalignment and excessive wear.

The latest company to announce the development of such a device in the market is MKS Instruments Inc.

The Ophir BeamSquared family

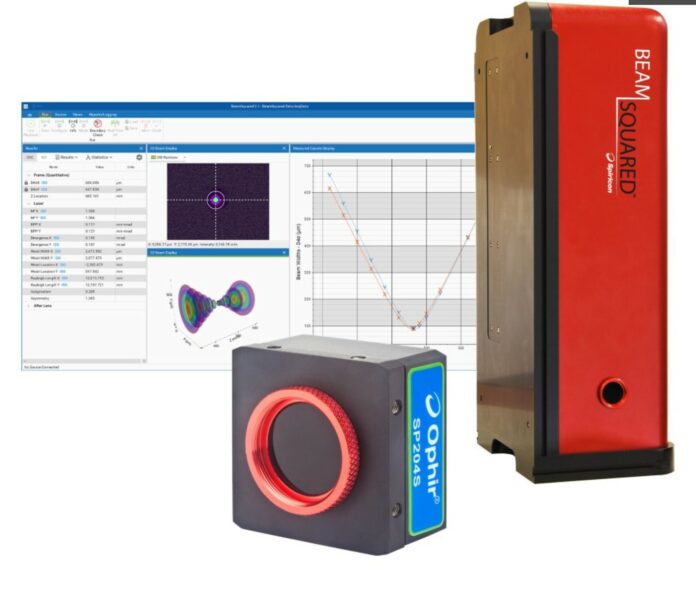

MKS Instruments, Inc. has launched the Ophir® BeamSquared® SP204S-PRO and Ophir® BeamSquared® SP1203 M2 beam propagation analyzers as part of the Ophir BeamSquared family.

The BeamSquared SP204S-PRO M2 analyzer is a compact, fully automated tool, that quickly and accurately measures the propagation characteristics of standard and large-diameter CW and pulsed lasers with extended Rayleigh ranges (up to 40 meters). The BeamSquared SP204S-PRO M2 analyzer is designed for manufacturers in high-precision production environments that need precise characterization of key beam parameters, including M2, waist position, astigmatism, and beam symmetry.

The BeamSquared M2 beam propagation analyzer family also added the BeamSquared® SP1203 analyzer, which includes the Ophir SP1203 GigE beam profiler. This high-resolution beam profiler is able to precisely measure smaller beam diameter lasers (up to 150 µm in the SWIR and NIR range) with larger Rayleigh lengths that need to be focused into tighter spots. This allows the BeamSquared SP1203 M2 system to be used in a broader range of advanced applications, including telecommunications, advanced manufacturing (welding, cutting, 3D printing), autonomous vehicles (LiDAR), and medical devices (ophthalmology and optical coherence tomography).

“The evolution of advanced laser systems has prompted top manufacturers to seek more accurate ways to validate performance for demanding customer applications,” said Reuven Silverman, General Manager, Ophir Photonics Products. “Manufacturers were dealing with large errors in astigmatism and waist location measurements, as well as quality control over the UV to NIR spectrum. The new BeamSquared M2 analyzers address these concerns. They deliver the most accurate products on the market, combining ISO 11146 compliance, accurate beam caustic measurements, and expanded laser characterization features. This allows continuous process manufacturers to tune lasers with optimal precision and reliability.”

The BeamSquared M2 analyzers include Ophir BeamSquared software, an optical train, and a high-resolution camera. The newest analyzers feature a longer optical train and patented UltraCal™ advanced calibration software to deliver high-precision beam analysis for lasers with extended Rayleigh ranges up to 40 meters. The software measures beam propagation characteristics on both the X and Y axes, including waist diameters, full angle divergences, waist locations, Rayleigh lengths, M2 or K and BPP factors, astigmatism, and asymmetry.

The system displays 2D or 3D beam profiles for visual verification of beam behavior through focus. Functions include a 3D slice display and the ability to add 3D displays to reports. Reports can also incorporate a beam caustic chart, in addition to setup information, laser measurements, and a variety of statistics. An automation interface via .Net components allows users to build custom applications that incorporate the laser beam analysis and processing power of the BeamSquared system.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.