The term Internet of Things, short for IoT, has become so pervasive in industrial communication that manufacturers have (un)consciously acknowledge its pivotal importance for manufacturing without truly assessing and understanding its uses, benefits and how it actually impacts manufacturing. We have decided to shed light on this grey area in regard to the current additive manufacturing industry.

Is “the combination of IoT and Additive Manufacturing in the same sentence” only meant to create a buzz? Does IoT truly have the potential to disrupt AM? Or is it the reverse? The term that was coined in the 1990s for the first time, seems easy to understand and refers to a system of interrelated, internet-connected objects that can collect and transfer data over a wireless network without human intervention.

At the beginning, the term first embodied the concept of home automation, which includes but is not limited to lighting, heating and air conditioning, media, security systems as well as camera systems. The first goal at the time was to save energy by automatically ensuring lights and electronics are turned off or by making users aware of usage.

Over time, with the digital transformation of manufacturing, manufacturers have outlined this system of interrelated points as a core component of industrial transformation efforts hence the term Industrial IoT (IIoT).

The term has generated so much media hype that manufacturers often describe it interchangeably both as a module or an application. We have asked Gravity Systems, Nano Dimension and Twikit to clarify this grey area for us, and we came to realize that depending on the final purpose, IoT can be seen as a module and as an application.

Martijn Joris, founder & CEO at Twikit states from the outset : “The relation between IoT and AM goes in both directions. IoT can be used to industrialize AM processes, just like AM can be used to prototype and produce IoT devices.”

“We believe that IoT is rather a module than an application. Depending on the utility of the IoT device, its purpose is mainly ‘data collection’ in our case. Therefore, we use IoT more intelligently than a simple hardware ‘add-on’. Data collected from a single device is usually part of a larger transaction where multiple devices and potentially additional business logic are needed to complete a transaction. We implement that consistency right in the edge”, outlines Huba Horompoly, Founder & Managing Partner at Gravity Pull Systems, Inc..

“For Nano Dimension, it’s an application. For us, IoT is something that needs to communicate. The recent advancements of additive manufacturing are currently enhancing product development processes and the way engineers design for several vertical markets. When we look at what we call “Additively Manufactured Electronics” (AME), there is a big potential for IoT devices”, states Valentin Storz, VP Marketing & General Manager EMEA at Nano Dimension.

That being said, the lines below will look at IoT as a module and IoT as key vertical.

How is “IoT” utilized as a component of AM production?

IoT solutions encompass everything designers, software developers and product manufacturers need to develop and implement ideas. They can include hardware IP and software platforms. Put it this way, IoT solutions look like everything and nothing at the same time.

From a technical perspective, IoT systems provide a reliable logic structure that can bring autonomous systems together, communicate and interpret data at a level unfathomable by human intelligence.

IoT solutions would therefore be a great advantage for sectors that are looking for digitizing their manufacturing processes, and introducing control as well as monitoring systems along the shop floor. For several industrials, Internet functionalities and data-based services aim to strengthen a production based on the Industry 4.0 paradigm, hence the terms advanced manufacturing, digital factory or industrial Internet of Things generally associated with IoT. In the additive manufacturing industry, one company that has developed a dedicated IoT solution for the industry is Gravity Pull Systems, Inc. The Swiss software company has developed a software platform named Synoptik that reduces complexity in AM by enabling holistic process planning. Unlike other software systems of the same range that integrate individual single-point functions, Synoptik’s approach enables best-practice applications for industrialised AM processes, from order entry, initial planning to production completion, including post-processing.

“Our IoT solution does not require specific tasks”, Horompoly explains. There are several in-situ process monitoring applications available on the market. We excel in integrating the information generated by those solutions with our production logistics IoT apps, so we get a holistic picture immediately with analysed co-relations instead of a set of ‘raw data’ only. We do not simply collect raw data with our IoT apps and self-developed sensors but put them into the right context; this enables Synoptik to give recommendations on possible actions, to react on IoT generated events in real time. Since our software links every event with costs, we recommend the optimal course of next actions not merely on the logistics level, but also based on financial insights that our optimizer detects based on pre-defined cost accounting principles.”

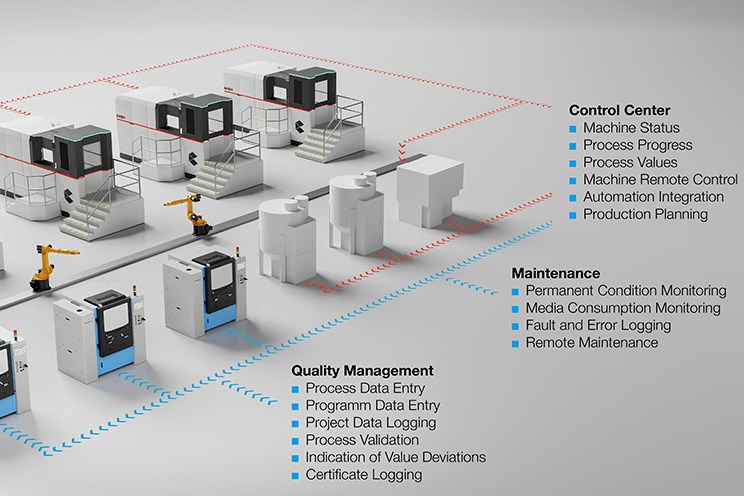

As far as hardware is concerned, a company that has recently introduced IoT solutions dedicated to the post-processing stage of manufacturing is Solukon Maschinenbau GmbH. Their “Digital Factory Tool” encompasses production control, maintenance management, integration of automation and process validation / quality management.

We would like to draw attention to the production control where the machine manufacturer has integrated an OPC-UA interface* into its SFM-AT800 to allow for central controlling and monitoring. For those who do not know, OPC-UA stands for Open Platform Communications United Architecture. It is a platform that provides the necessary infrastructure for interoperability across the enterprise, from machine-to-machine, machine-to-enterprise and everything in-between. At Dresden-based Fraunhofer Institute for Machine Tools and Forming Technology (IWU), there is a Solukon SFM-AT800 that integrates this OPC UA interface within a modular robot cell. Operators of this Solukon system explain that the robot cell is an example for downstream processing. Apart from powder removal, the robot cell includes a system for optical analytics of the geometry and a system for support removal, not to mention that it can also perform part loading and other jobs related to metal cutting. As pointed out by the concept of OPC-UA, each of these stations communicates with each other.

A scenario where IoT solutions are well integrated in a smart manufacturing environment is ideal for any industry, but its share of challenges often slows down its proper integration. These challenges include for instance:

- Vulnerable components. Given the interconnection with a number of security disciplines, it is important to look at the convergence between IT security, OT security and physical safety and the shift from closed to connected cyber-physical systems.

- Supply chain complexity. This is a “pain point” for manufacturers of products who often rely on third parties’ components for certain productions. This might result in an extremely complex supply chain with a large number of people and organisations involved that need to be managed. According to the team of security experts at Secure Thingz Ltd., not being able to track every component to its source means not being able to ensure product security, which is only as secure as its weakest link.

- Another challenge comes with the fact that industries need to secure product lifecycle – “device security should be a subject of consideration through the product’s entire lifecycle, even end-of-life/end-of-support of the machine.”

Other challenges might include the “safety aspect”, the “human factor”, the security updates, and the challenge of handling all that data.

When asked how their solution addresses this security issue as part of an AM production environment, the Managing Partner at Gravity Pull Systems, Inc. declares:

“We developed a solution where any machine (or manually) generated data is validated by a private/public key pair, the validator being installed on a NFC Chip. Before being saved in a database or a blockchain, all data go through this process. We ensure end-to-end data transparency by the application of this infrastructure.”

Despite its great promise, the truth is Industrial IoT is still nascent. The main use cases that have already demonstrated the potential for smart manufacturing include quality assurance and machine monitoring. So far, no current communication standards have been developed for IIoT devices, which means that to get machines to communicate with IoT devices, and with each other, it’s up to each organization to create its own interpreter software or to rely on third parties software providers like Gravity Pull Systems, Inc.

A look at IoT as a key vertical

Exploring IoT as a key vertical implies the use of AM technologies to enable IoT applications or to fabricate IoT devices. Interestingly, a recent report from Market and Markets estimates that the smart manufacturing market would be worth $384.8 billion (€356.1 billion) within the next four years. A significant portion of that growth is 3D printing and its implications in the evolvement of IoT applications. Before diving into examples of applications, a quick look at AM technologies shows that 3D printed electronics is one of the key enablers for such applications.

While engineers can easily move from large wet-process factories to small labs and office spaces, according to Nano Dimension’s Valentin Storz, “there is a wide range of advantages when leveraging AME for IoT applications. 3D printing electronics allows engineers to produce and test a single IoT device in a day to assess its performance, not to mention that it enables lower material costs and lower waste. Furthermore, in sensor design, conductive elements can be printed directly on the board without using an etching and plating process.” We learned thereafter, that this latter advantage becomes very interesting for the development of capacitive touch sensors, strain sensors, or chem-resistive environmental sensors.

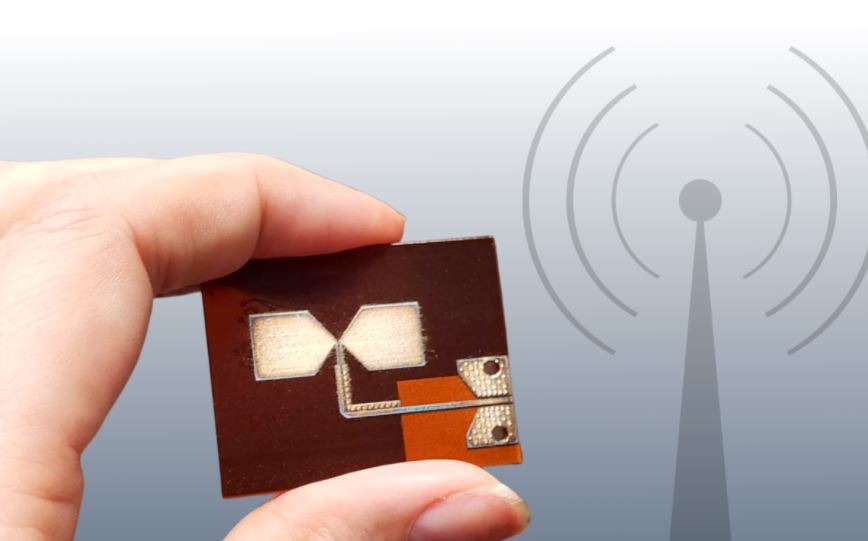

The General Manager EMEA at Nano Dimension explains that with 3D printed electronics, engineers usually benefit from agile workflows. It should be noted that, to achieve full interconnectivity between a wide range of objects for IoT, engineers must rely on both a transmitter and receiver (transceiver) to create the communication and connection between two objects.

Speaking of IoT devices and the way they are produced, Storz states: “IoT devices are smarter and more connected. Due to their use of both analog and digital signals, designers need to follow certain guidelines in the design phase. There are devices that need to communicate, that’s why engineers will need to integrate wireless communication capabilities in their PCB. One way to do that is to embed an antenna and transceiver in the board.”

Another method will consist in designing a printed antenna for the board manually. Since with 3D printed electronics, one can print directly on the substrate, engineers can thereafter easily adapt the board to antenna designs for IoT devices.

Low pass filter (LPF) devices are another interesting application that is worth noting. According to Storz, most common use of LPF devices is between RF transmission amplifier and the antenna. Therefore, it encounters widespread use in application such RF IoT devices and other RF communication devices.

Compared to conventional manufacturing processes, Storz notes that all the manufacturing stages of producing IoT devices can be done in one step with 3D printed electronics.

“We did some tests to assess the performance and quality of 3D printed IoT devices we produce using our technology. We realized that 3D printed electronics provides exceptional results as the devices were higher than devices produced with other technologies and this performance was especially related to data transmission and quality. We learned that antennas that require a ground plane should be printed on multilayer boards, and that RF communications circuits/devices are one of the applications that will benefit the most from 3D printed IoT devices”, Storz concludes.

Lastly, the advantages of using AME for the manufacturing include light material, low outgazing, and low price for unique applications.

In addition to prototyping new devices, and micro-manufacturing smart sensors, AM remains a good production candidate for IoT home devices. In the upcoming years, it will probably be complicated to list all the specific devices and sensors AM can help to produce.

However, for an “applications” dedicated- company like Twikit, AM technologies make IoT applications at a higher flexibility than before. You can produce your unique board instantly instead of waiting a long time before receiving your copy.” “As always, we will first look at the added value of the application before deciding on which technologies to use. Projects have passed where casing of IoT devices were produced with AM, as well as a project where IoT was used for part identification in the AM process”, Joris concludes.