The European Commission’s Horizon 2020 recently funded the 4D Hybrid project which aims to develop a new concept of hybrid additive manufacturing, supporting the Maintenance Repairing Operation (MRO) value chain.

During the European Research & Innovation Days held in Brussels, the 4D Hybrid project and SUPSI received the Overall Grand Prix of the Innovation Radar Prize 2019, as well as the women-led innovation category prize for 2019.

The 4D Hybrid project

The project gathers 20 partners from 10 countries. Led by PrimaIndustrie, the group includes 12 industrial players that operates as technology suppliers, end users, and as Communication and Dissemination partner.

However, Professor Anna Valente, Head of ARM (Automation, Robotics and Machines Laboratory) at SUPSI-DTI, shed light on this innovation, that laid emphasis on medium to large size high-added value components.

The first two years of the project saw the launch of an autonomous robot

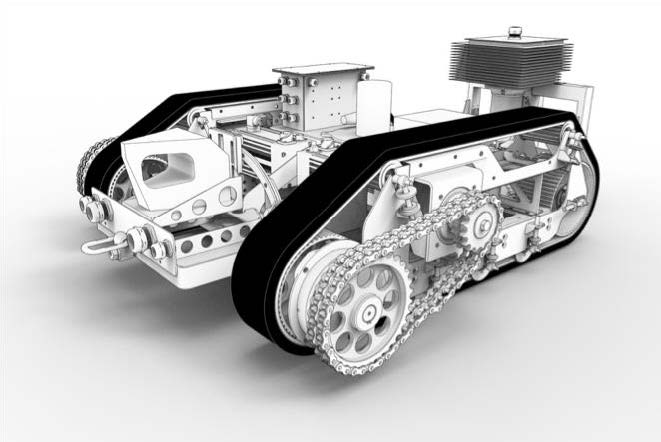

During the first two years following its launch, researchers developed an autonomous robot that can detect and repair vertical metal surfaces, including in offshore environments. Designed to repair all metal surfaces, the robot can work with an outside temperature ranging between 3°C and 35°C.

Furthermore, as shown on the picture, it integrates two robust rubber belts that facilitate adherence to the surface.

It also integrates a 3D Scanner and a Cold Spray gun. Manufactured by Luxembourg-based specialist Artec, the 3D scanner is able to reconstruct the surface and individuate the corrosion/defects on the metal surface.

Furthermore, when the Cold Spray Gun is harnessed in open environments, a recovery system that sucks up the powder and carries it to the top of the ship enables to reduce the dispersion of powder.

The next step for PrimaIndustrie is to include the deposition modules in the company product portfolio and for Comau to launch a new generation of robots for additive manufacturing and milling operation.

Focus on maintenance costs and repair operations

To address maintenance costs and repair operations issues encountered in aerospace, oil & gas and power generation industries, participants of the 4D Hybrid project developed a new concept of additive manufacturing based on the modular integration of compact and low-cost modules.

When performing, this process reduces repair cost throughout different stages of product lifecycle.

During this project, participants have been able to prove that 4D Hybrid can be integrated into various types of manufacturing equipment, therefore removing the necessity to apply major changes in the facility.

While saving time, this level of adaptability and flexibility will ensure a faster and efficient absorption of project results.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !