Siwtzerland-based materials producer, Suprem, has launched a new line of materials for continuous fibre 3D printing.

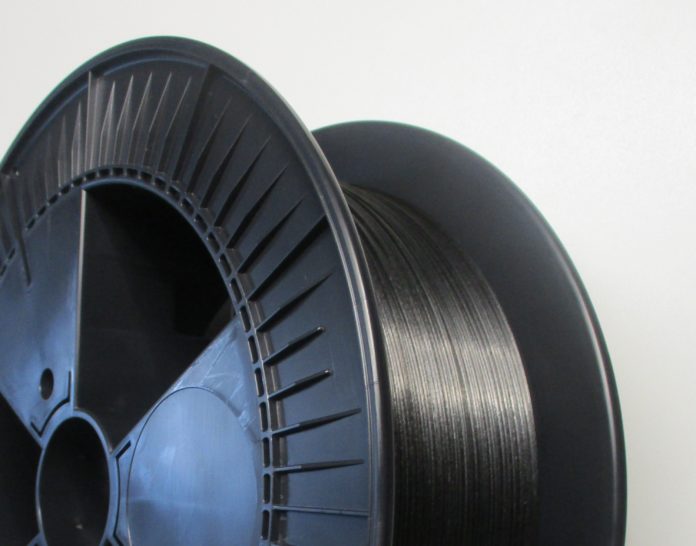

Named Filaprem™, the new materials are tailored to replace steel, titanium or aluminum alloys by composites as well as to locally strengthen plastics. It will make parts lighter and stronger.

The high and consistent quality of Filaprem™ with good fibre/matrix distribution and low porosity enable to print parts with low downtime and minimal scrap. High mechanical performance and appropriate temperature resistance are achieved thanks to engineered polymers and fibres.

Suprem relies on 35 years of experience in developing and manufacturing products for additive manufacturing. Its operations are driven to support customers projects from prototype up to large scale production. Suprem’s materials are applied in various applications from down the oceans up to the space.

“I am very pleased we can transfer our long-term experience in continuous fibre reinforced thermoplastics into 3D printing. This additive manufacturing technology opens new opportunity for designing small and complex parts as well as remote automated manufacturing. Filaprem™ materials will contribute to the industrialization and democratization of 3D printing with continuous fibre”, Dr. Anatole Gilliot, CEO states.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com