When it has opened a $500,000 additive manufacturing materials development lab in collaboration with coating expert SDC Technologies, B9Creations states they ambitioned to bring new materials onto the market at an “aggressive pace”.

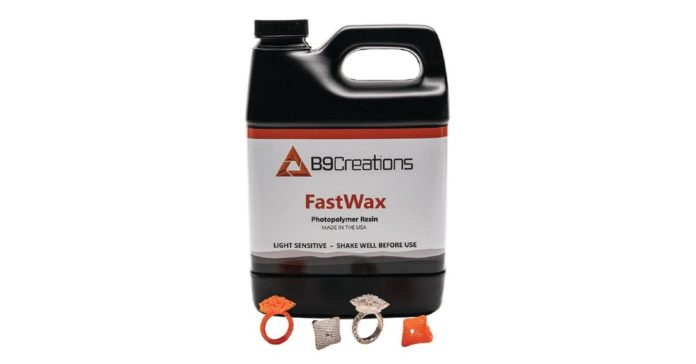

The US-based 3D printer and materials manufacturer unveiled last year a FastWax Castable resin; a 3D printing material that would offer all the benefits of wax.

B9Creations explains that the material would reduce the post-processing steps including polishing with the smoothest surface finish. Durable enough to ship or use for customer try-ons, FastWax enables the smoothest surface yet, while capturing intricate features that traditionally require molds.

Those features could meet applications in the jewellery, medical prototyping and manufacturing, research, and model making industries.

Jewelers especially could print perfect-fit settings, smooth shanks, and sharp detail. “I casted a piece that typically requires a mold, and I couldn’t cast it directly in another material. I think FastWax gives the best result yet on difficult geometries,” a custom jeweler beta tester shared.

FastWax joins B9Creations’ castable material line that includes Emerald and Yellow resins. Emerald makes the finest design details visible for validation with customers while casting flawlessly, with Yellow offering the industry’s cleanest burnout, leaving no ash behind. Now FastWax provides the most forgiving burnout for your complex designs or simply for ease of use, delivering flawless prints without requiring vat heaters or sensitive temperature regulation. All resins cast into materials of gold, silver, platinum and more.

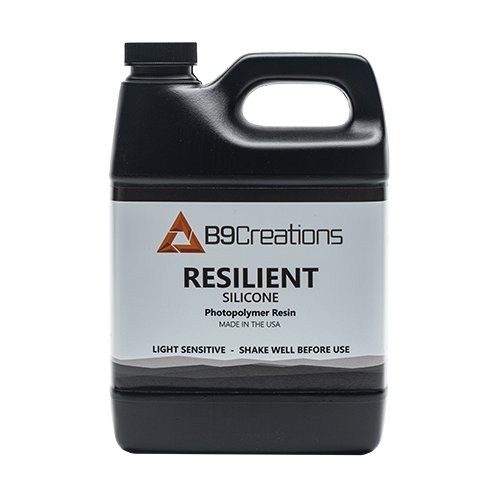

Furthermore, this launch is followed by the development of 3D printed jewelry moulds created using a new elastomeric formula, Resilient – Silicone resin. The material expert explains this new mould-making material is a high-detail, less costly replacement for traditional rubber jewelry moulds, offering flexibility for easier removal of delicate materials, such as wax, and able to deliver high-volume runs for mass production of jewelry.

If you are a jeweller, then you certainly know that with 3D printed jewelry moulds, one can exactly duplicate mould designs and achieve accurate geometry of mating parts. B9Creations says it can offer 3D printed moulds that cost less than $10 and can be mass produced in just minutes, enabling creation of jewelry designs—like round objects, hollow filigree beads, and two-tone castings—that are more costly to create with conventional methods, and take longer as well.

The B9 Core 5 Series XL 3D printer, the company’s largest-format system as of right now can perfectly process this new Resilient – Silicone resin. With a build volume of 124.8 x 70.2 x 127 mm and < 25 micron effective resolution, the 3D printer provides users the ability to take advantage of both a larger build area and better accuracy for high-precision jewelry molds at volume production.

“Jewelers have always been one of our most valued customers – and sources of insight. While we’ve gotten great feedback on our Emerald and Yellow castable resins since their launch, we’ve continually heard from jewelers asking for ways to streamline their workflow, cut down on post-processing, and enable them with quicker turnaround to serve their customers better and faster than ever before. That’s why we developed FastWax, for the smoothest surface yet without loss of detail, to significantly cut down on their polishing and post-processing time,” said Shon Anderson, B9Creations CEO.

Supporting individuals with disabilities

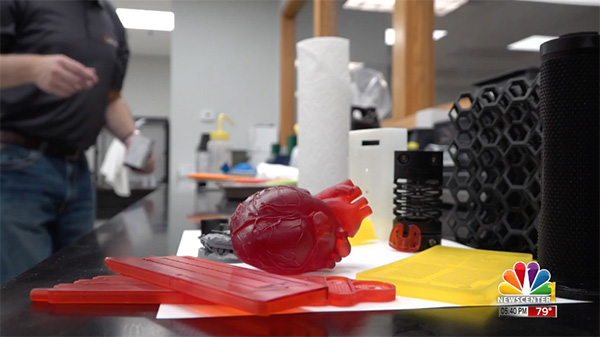

As part of its activities, B9Creations has leveraged its expertise and technology solutions to provide individuals with disabilities greater independence.

The company has been working with Black Hills Works, an organization that provides homes, employment, recreation and social outlets for adults with disabilities. Together, they produced 3D printed assistive devices for over 600 people in need. B9Creations has been specifically providing design services, training, and medical-grade 3D printing technology as part of the project.

These devices enable to facilitate the handling of eating utensils to grips for wheelchairs, waterproof call lights, tools used in the workplace and more.

As Anderson notes, “assistive devices are vital to people’s lives, but are often costly, time-consuming to produce, and unable to meet individualized needs. It is very rewarding to see technology being used to transform people’s lives and give them greater independence.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com