Every major progress achieved in the Additive Manufacturing industry comes with an array of challenges that might slow the wider adoption of this technology in industrial environments. An accurate observation demonstrates that, at the heart of these challenges, there are standards. Companies keep innovating, but seem to take one step forward and two steps back because of a lack of points of reference. And yet, organizations do exist, do follow the various roads that AM technologies are taking…So, let’s take a deep breath to discover where the market is.

Speaking of standards is not very ‘sexy” for a debate but it is a necessary one since it provides a basis on which the industry might be built. So, to avoid any confusion, we refer to “standards” as those technical methods, processes, specifications, and definitions with respect to a sector of activity on which a general agreement has been promulgated by recognized standards organizations.

Let’s be clear. We will not talk about the technical specifications of every method, only about the framework that enables the industry to move forward.

Vincenzo Renda, Innovation Policy Officer at CECIMO, the European Association of the Machine Tool Industry and related Manufacturing Technologies, has provided key answers to our questions in this paper. In a few words, the innovation policy officer, is responsible for EU Additive Manufacturing, policy advocacy, engaging with the European Institutions and stakeholders on various issues including skills, standardization and market access requirements.

We met Vincenzo at the conference “3D Printing within the Plastics Converging Industry” that took place on May 14th at Brussels.

Organizational structures for AM Standards

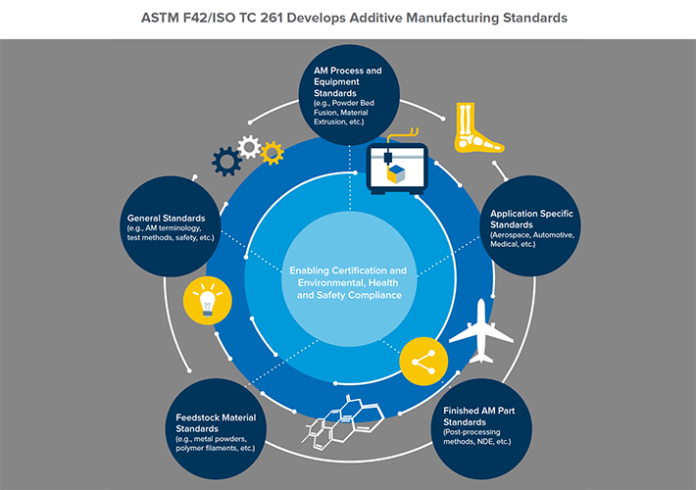

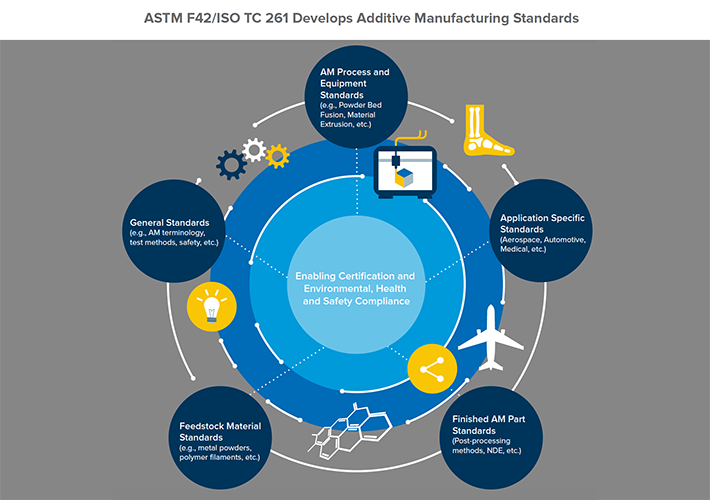

There are a lot of organizations that are in charge with developing a consensus for AM standards. The well-known structures are: ASTM International, ISO – International Organization for Standardization, Nadcap, ANSI – American National Standards Institute, SAE international, ASD-STAN, bsi., and NIST.

Even though some of these organizations have offices worldwide, it should be noted that standards differ from one continent to another.

However, experts plan to define a common roadmap for Europe & the USA regarding the application of 3D Printing technologies.

So far, among the joint standards that are currently being developed, one notes: ISO TC261 and ASTM F42. The two organizations (ASTM & ISO) have agreed to normatively reference their standards in the publications of the other. According to ISO website, the working group that includes 23 participating members and 9 observing members has already published 9 ISO standards and are developing 25 other ones. These standards mainly concern specifications for Extrusion Based Additive Manufacturing of Plastic Materials.

In the European market in general, only 23 international standards are already released (for terminology design, powders, materials, test methods, health and safety) and 40 more standards are in progress.

Key factors to consider while developing AM standards

At the European level, organizations take in charge 4 main features in the implementation of a standard: compliance, right level of regulation, trade deals and product nomenclature.

First, compliance. Products manufactured within the European Union usually have the CE-mark. However, as mentioned in the Bonus Topic of 3D ADEPT Mag – April Issue, medical devices show other constraints regarding this issue.

Right level of regulation. This seems obvious when we take into account the increasing number of counterfeit risks. Both companies and individuals are increasingly looking for solutions to exercise their intellectual property rights when it comes to their technology or files.

As far as trade deals are concerned, it is no secret that the additive manufacturing industry is an industry that is both globally & locally based. Even though there is an increasing interest in the Asian market, for now, there are a lot of regulations that are currently being implemented regarding AM Trade barriers; regulations in terms of double certification and costly conformity assessment. As a matter of fact, the EU-US industrial good deal is a recent example.

Lastly, product nomenclature. New codes are required to track AM machine exports more accurately.

Challenges & benefits of standards application to AM

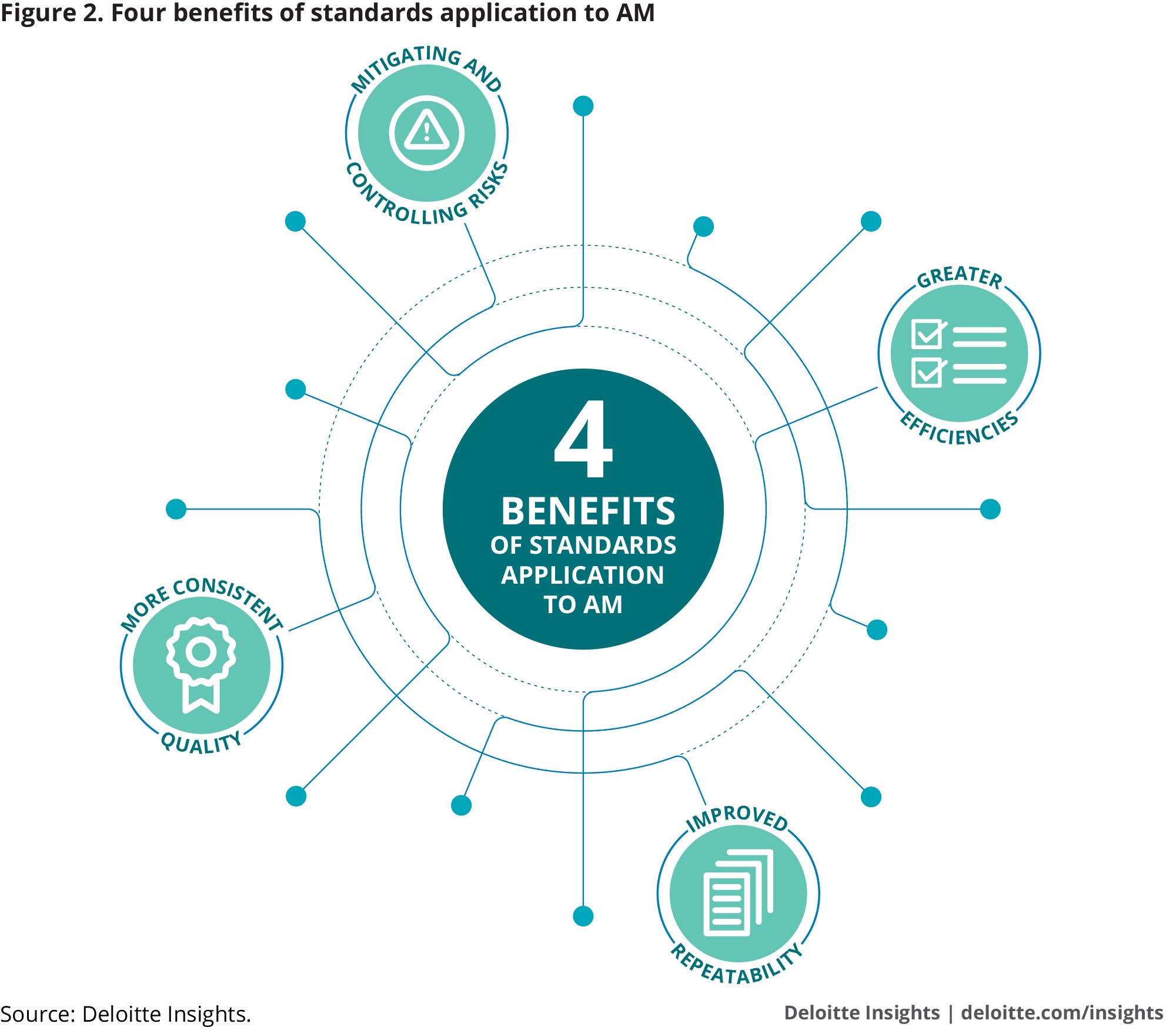

Deloitte’s recent report on standardization for AM points out 4 great benefits when applying standards to AM: Mitigating and controlling risks, Greater efficiencies, Improved repeatability and More consistent quality.

However, three main challenges still remain at the levels of materials, process control and certification.

Let’s take Metal AM for instance. Metallic powders are used by various demanding industries but materials experts keep underlining that there are still a lot of standards that do not exist for these materials. As a result, manufacturers cannot for instance determine all values. Furthermore, due to the lack of 3D printing material specifications – which definitely affect the way the part is manufactured -, there is also a certain limitation in terms of design and process control data.

Some companies believe that, one way to overcome this challenge (at least, to partially overcome it) is to adopt existing standards, that have been implemented for conventional materials. However, it should be noted that, this solution cannot be applied in its entirety as there is a big difference between the mechanical behavior of AM parts and conventionally made counterparts.

Lastly, if certification requires time and resources, process control mainly highlights the inability (or unwillingness) of some manufacturers to share data on process variable optimization which may affect some properties of 3D printed parts, hence the need of collaboration and open platforms.

To sum up, there is still a long way to go to achieve standardization for all AM-related issues. The good news is that, companies rely on partnerships/collaborations to move forward.