Sinterline® is a brand of Solvay Performance Polyamides, dedicated to supporting companies in their industrial transformation at several levels.

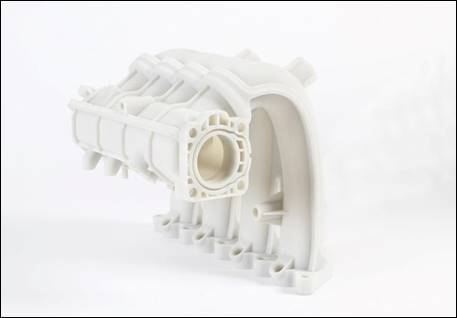

The brand’s solutions include Sinterline® Technyl® polyamide 6 (PA6) powders, intended for high temperature SLS 3D printers. These materials deliver the mechanical and thermal performance required to manufacture functional prototyping and low to medium volume production.

Their development required a patented polymer and a specific formulation, that are now compatible with a wide range of SLS 3D printers.

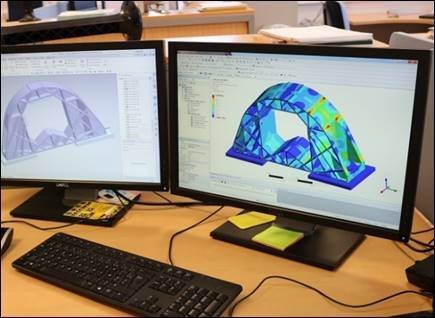

“The industry has realised the full potential of additive manufacturing and is moving from prototyping to serial production. To accelerate this transformation, solutions need to be developed to deliver real functional prototypes, closer in performance to injection molding parts,” says Dominique Giannotta, Sinterline® Additive Manufacturing Leader for Solvay Performance Polyamides. “This is where Sinterline® enables affordable customisation of functional 3D printed parts that could not previously be manufactured without great expense, time and material wastage. Parts’ performance is improved thanks to HUB by Sinterline®, an advanced service platform which includes predictive simulation capabilities specifically designed for additive manufacturing.”

HUB by Sinterline® connects upgraded advanced services specifically designed for 3D printing.

Photo: Solvay Performance Polyamides.

According to the company, HUB by Sinterline® connects together MMI® Technyl® Design predictive simulation for 3D printing, an advanced service powered by Digimat® from e-Xstream, an MSC Software Company.

The service brings out mechanical performances with a high level of accuracy, and delivers a Sinterline® functional prototyping service and application testing centre (APT®) in order to provide customer innovation with enhanced capabilities and synergies for efficient design and optimized performances.

With the Sinterline® brand, Solvay demonstrates its ability to diversify its offering in the additive manufacturing industry and it looks like we haven’t yet finished to talk about the company’s developments.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com