Just after the announcement of its 3 polymeric filaments for the 3D printing of parts, Solvay continues its adventure with its first signed partnership, e-Xstream engineering.

This software publisher and engineering services provider focuses on the multi-scale modeling of composite materials and structures, which enables the Belgian group to offer 3D print simulation solutions. Solvay’s goal is to increase the number of specialty polymers available for simulation on the Digimat® platform to enable customers to achieve “a perfect first-impression with Solvay’s high-performance thermoplastics.”

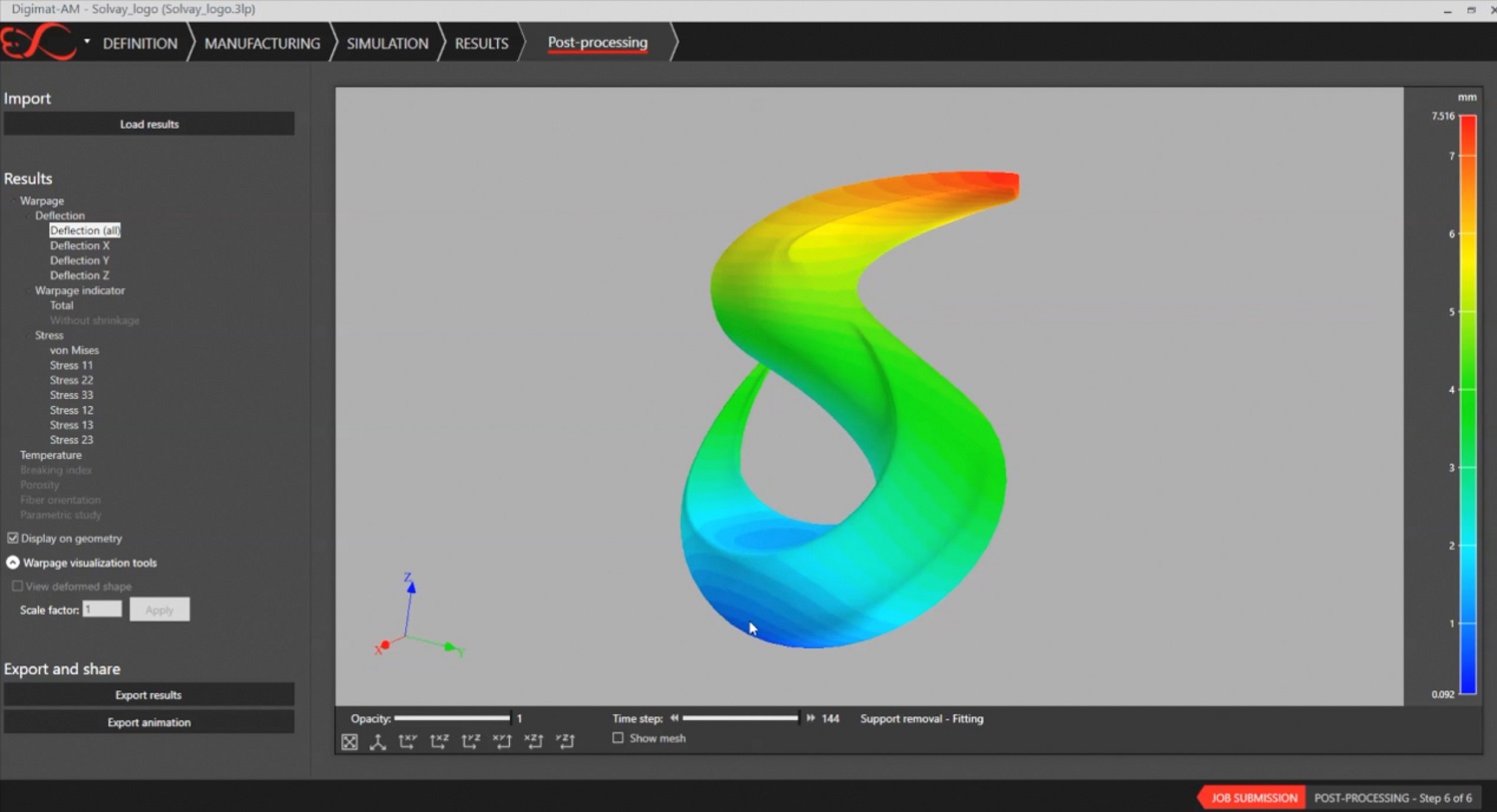

The Digimat® platform

By working with Digimat®, engineers and designers can better predict the deformation and residual stress of 3D printed KetaSpire® PEEK parts, depending on the type of technology used, including FFF technology.

As a reminder, the PEEK AM KetaSpire® filament offers superior mechanical and chemical resistance for 3D printed parts. Generally speaking, Solvay’s advanced PEEK polymer was limited to conventional processing methods. But, the new PEEK AM KetaSpire® filaments now make this material an option for additive manufacturing applications requiring superior end piece performance. “Solvay’s combination of industry-leading materials, expertise and collaborative innovation enabled us to develop highly accurate predictive modeling data for KetaSpire® PEEK AM filaments,” said Roger Assaker, CEO of e-Xstream engineering and chief material strategist for e-Xstream’s parent company, MSC Software. “As a result, Digimat® simulation software offers additive manufacturers cutting-edge new material options to push the design boundaries of their 3D-printed parts.”

“Solvay’s combination of industry-leading materials, expertise and collaborative innovation enabled us to develop highly accurate predictive modeling data for KetaSpire® PEEK AM filaments,” said Roger Assaker, CEO of e-Xstream engineering and chief material strategist for e-Xstream’s parent company, MSC Software. “As a result, Digimat® simulation software offers additive manufacturers cutting-edge new material options to push the design boundaries of their 3D-printed parts.”

The launch of e-Xstream engineering’s Digimat® simulation software is scheduled for June 2018 and the PEEK AM KetaSpire® filament will be the first polyetheretherketone polymer to be integrated. It is already possible, upon request, to receive the new data file describing the material law of PEEK KetaSpire®.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com