Velo3D offers end-to-end metal additive manufacturing (AM) solutions comprised of the Sapphire production system, Flow print preparation software, and Intelligent Fusion™ technology.

We were expecting such a news…Less than one month after the launch of Sapphire System, Velo3D signed a collaboration with Incodema3D whose one of the divisions specializes in Contract Additive Manufacturing.

We were expecting such a news…Less than one month after the launch of Sapphire System, Velo3D signed a collaboration with Incodema3D whose one of the divisions specializes in Contract Additive Manufacturing.

A metal 3D printer of this caliber needed an appropriate software to foster the development of metal 3D printing; and Velo3D has found the right partner in Incodema3D.

The partnership brings together Velo3D’s Sapphire™ 3D print system and Flow™ software with Incodema3D’s production scale manufacturing capability, enabling greater innovation for design and production of parts. Both companies will address issues such as product design limitations, part-to-part consistency, process control and cost-effective manufacturing.

For Greg Galvin, executive chairman, Incodema3D, “the Velo3D Sapphire solution complements our manufacturing capacity and opens the door to new production opportunities that will drive further adoption of metal additive manufacturing. We look forward to accelerating our growth with this partnership.”

3D Systems updated its software suite

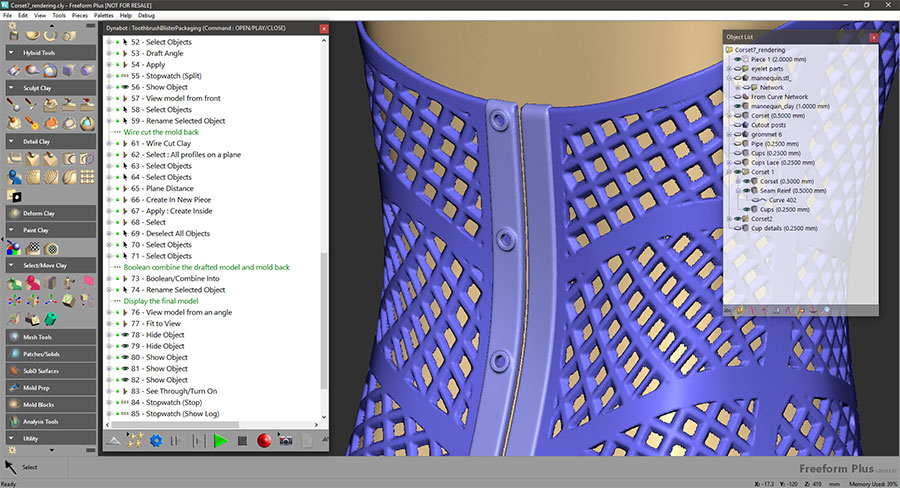

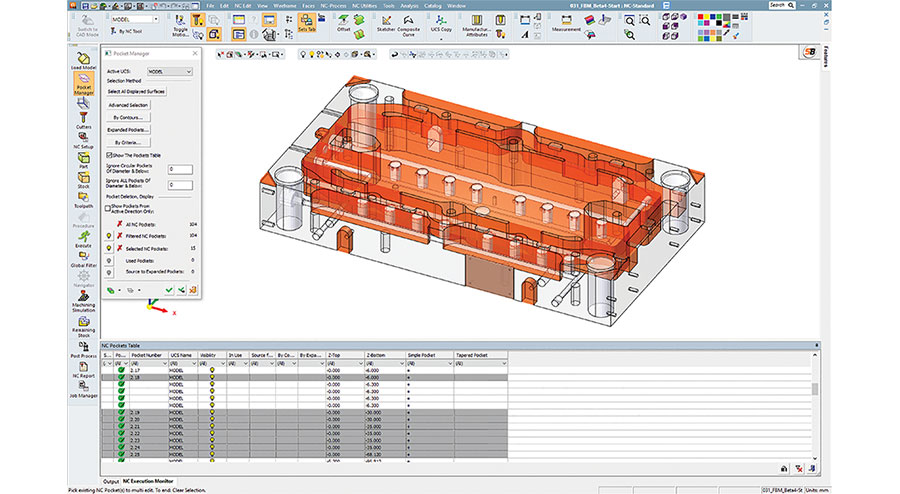

3D Systems recently released an updated end-to-end software portfolio. 3D Systems now provides its customers a unique software platform that addresses the entire manufacturing workflow and delivers competitive advantage. 3DXpert™ 14; GibbsCAM® 13; Cimatron 14, Geomagic Freeform® 2019; Geomagic® Design X 2019 as well as 3D Connect™ Service are part of the major software which have been improved/released by the company.

Apart from Geomagic Freeform 2019, GibbsCAM 13 and Cimatron 14 which are dedicated to traditional manufacturing techniques, the rest is dedicated to 3D technologies.

Geomagic Design X 2019 is a reverse engineering software that combines feature-based CAD with 3D scan data processing. Geomagic Design X 2019 includes enhanced capabilities such as a streamlined direct scanning user experience, hole filling and automated file fixing, new sketching and blending tools as well as powerful surface fitting quality and continuity controls. The software will be available in Q4 2018.

3DXpert 14: This all-in-one software integrated the entire metal additive manufacturing workflow. 3DXpert encompasses preparation, simulation, optimization, and post-processing operations – resulting in a streamlined process to quickly and efficiently transition from a 3D model to successfully printed parts.

3D Connect Service: The Industrial Internet of Things (IIoT) is becoming reality for manufacturers, and software will play an integral role in managing the ecosystem of additive manufacturing processes and support services. This software mainly provides real-time remote diagnosis, automatic support case creation, and usage-based preventative maintenance scheduling.

3DXpert 14 and Geomagic Freeform are now available whereas 3D Connect Service, GibbsCAM 13, Geomagic Design X are planned to be available Q4 2018.

For further information, follow us on our social media and subscribe to our newsletter! Would you like to be featured in the next issue of our digital magazine? Or subscribe to 3D Adept Mag? Send us an email at contact@3dadept.com