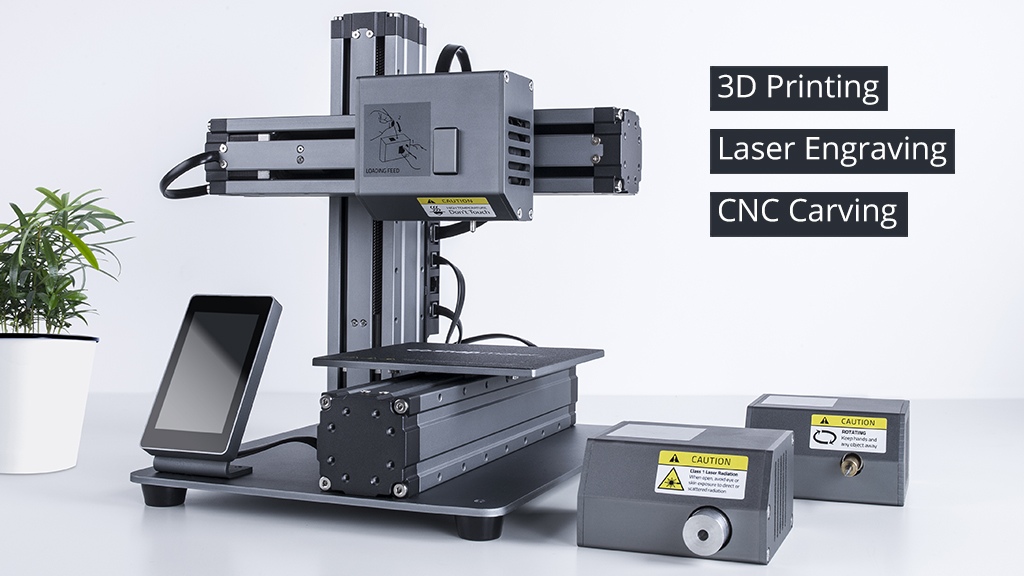

Snapmaker, the eponymous product of the Tech start-up, allows beginners and makers in general to use a multifunction printer at a lower cost. Entirely made of metal, it is an all metal 3D printer.

The truth is that one of the irritating things for “manufacturers” is to use several machines to achieve their work. Even if quality is to be recognized, high cost and production time are often an inconvenient.

What about this printer?

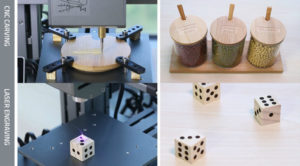

Snapmaker is a combination of 3D printers, laser engraver and CNC machine (Computer Numerical Control) made up of interchangeable heads. It uses the ACME lead screw as a drive mechanism to increase accuracy and capacity.

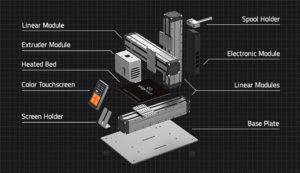

If the parts of the CNC machine play a key role in the quality, this extreme precision is also the result of a simplified

structure and an improved mechanical design.

A striking example is the one of a vase whose dimensions are length 64.5 x weight 64.5 x height 80.0mm. To print it, the Snapmaker team used 1.75 mm of PLA (Polyactic Acid) filament for a layer height of 0.2 mm. This took about 1h19mn.

In addition, parts are easy to assemble. Snapmaker also has a colour touch screen and an ideal platform for stickers.

In order to develop the production of this printer, a Kickstarter campaign during which they already succeeded to collect 1 478 000$, has been launched.

Until April 29th (end of campaign), according to contributions and from $ 299, contributors can their own Snapmaker printer with particular features.

Until April 29th (end of campaign), according to contributions and from $ 299, contributors can their own Snapmaker printer with particular features.