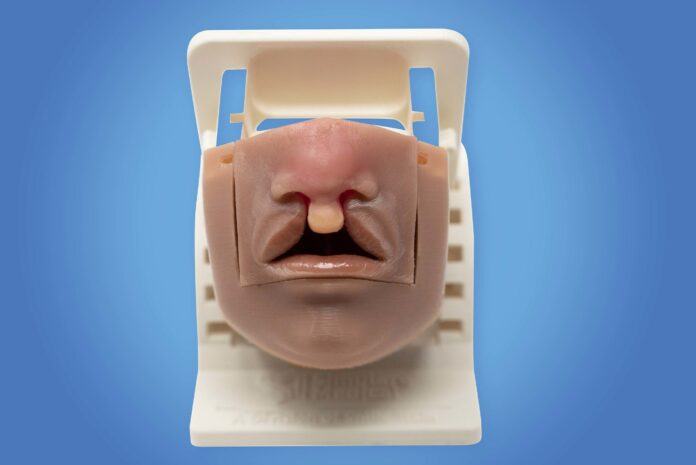

Simulare Medical, the surgical simulator division of Smile Train – one of the largest cleft-focused organizations -, has developed a bilateral cleft lip and palate simulator.

The patent-pending solution has been developed by plastic surgeons to help accelerate the learning curve in cleft lip and palate reconstructive surgical training.

Though children around the world suffer from both unilateral and bilateral clefts, traditional cleft lip/palate simulators have only addressed unilateral clefts. This Simulator goes beyond that, introducing a tool that can address bilateral clefts (i.e., involving both sides of the mouth). This additional functionality opens the doors for surgeons and trainees to be able to treat more children with refined techniques, the team at Simulare Medical explains.

This solution is an anatomically training tool that will reduce patient risk, decrease training costs, while enhancing surgeons’ skills in the field.

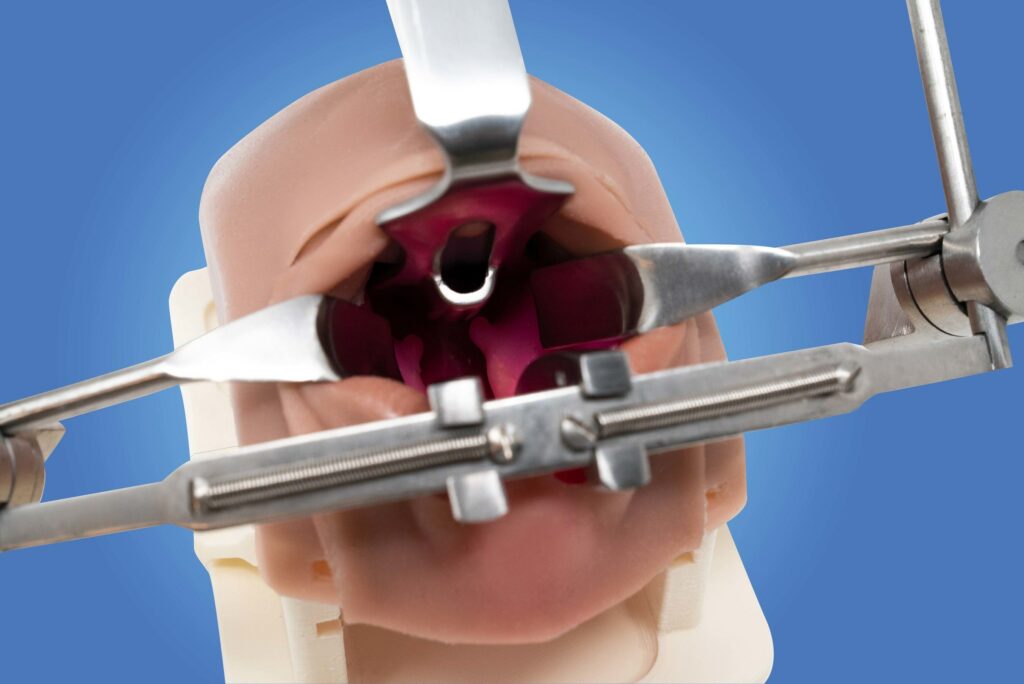

The development required the use of 3D printing and 3D software skills to achieve such lifelike effect and accuracy. While no detailed information has been given on the exact type of 3D printing technology used, a press communication said the use of 3D technology and 3D printed materials enables the Simulator to resemble the anatomy and different kinds of tissue, such as skin, muscle, and fat, found inside the mouth.

In addition to the advanced technology, the musculature and soft-tissue layers were developed from literature descriptions and consultations with expert cleft surgeons.

“This latest innovation advances our vision of providing care for every cleft-affected person and demonstrates our commitment to leveraging technology to further education and change lives,” said Susannah Schaefer, President and Chief Executive Officer at Smile Train. “We’re deeply invested in continuing to evolve training that creates more sustainable health systems. We look forward to seeing this Simulator have a positive impact on cleft surgeons at the beginning of their career and longtime professionals looking to refine their skills as well as on our beneficiaries — regardless of the type of cleft they have.”

With Simulare Medical handmaking its Simulators at its facilities in Canada, the division can ensure that each product is high-quality and will have an even greater impact on the patients who benefit from it. In international studies and training workshops, Simulare Medical surgical simulators are consistently recognized as a high-impact, hands-on, and low-cost way to develop and enhance surgical skills with no risk to patients.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com.