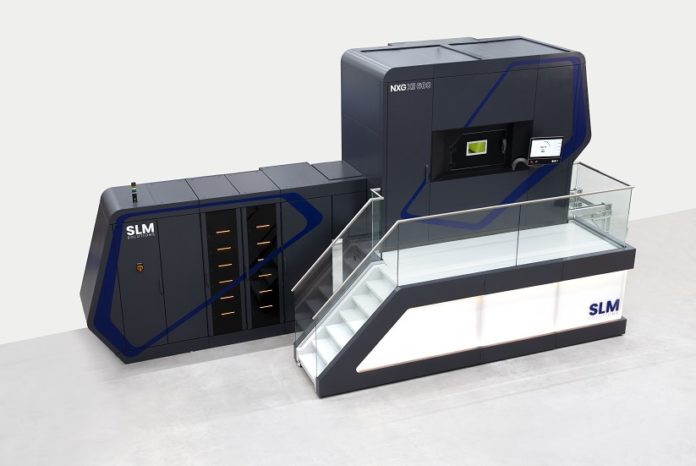

Aerospace parts producer Sintavia will ramp up its production capacity with two NXG XII 600 from machine manufacturer SLM Solutions. The machine has been unveiled in November 2020 and was described as a “miracle machine” in the German manufacturer’s portfolio – one of the main features being its twelve 1000W lasers and its large build envelope of 600x600x600mm³, which enables the production of large-scale components.

The tier 1 manufacturer of advanced propulsion and thermodynamic systems for the aerospace, defense, and space industry tested the machine on a benchmark part that proved to be one of the most challenging builds ever created using the LPBF process.

The results were astounding: the benchmark part, in this case, a large Inconel shrouded impeller with an exposure area of more than 50% and a weight of 174 kg was built successfully in under a week. This will enable Sintavia to go into serial production as soon as the first machine is delivered, SLM Solutions said in a press release.

“It is very clear that future flight and launch OEMs will depend on complex mechanical systems enabled by additive technology,” said Brian Neff, Sintavia’s founder and CEO. “The sheer size and efficiency of the NXG Xll 600 platform will greatly accelerate this profound modality shift. We are looking forward to unlocking its benefits on behalf of our aerospace, defense, and space customers.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com