Siemens is establishing the Erlangen location as a global research and development hub and the nucleus of global technology activities for the industrial metaverse.

Siemens continues to expand its footprint in key regions and applications that can foster the adoption of advanced manufacturing technologies. As part of its €2 billion investment strategy, the company will invest around €1 billion in Germany, thereby boosting the country’s innovative strength.

In the presence of German Chancellor Olaf Scholz, the technology company today announced the establishment of its new Technology Campus in Erlangen, Germany, with investments of around €500 million in the expansion of development and manufacturing capacities.

This means that Erlangen will be a global research and development hub and the nucleus of global technology activities for the industrial metaverse.

A closer look at Erlangen

With around 3,500 employees, the current location is already home to a world-class factory for key products in industrial automation and digitalization. Today, production in Erlangen is already highly automated, with humans and robots working side by side. Through this investment, Siemens is now creating a blueprint for the industrial metaverse, a virtual representation of the real world – photorealistic, physics-based and in real time. The targeted use of relevant, physical data and the application of artificial intelligence are creating the latest generation of high-tech manufacturing, which produces more sustainability and can respond flexibly to market changes.

According to Karsten Heuser, VP of AM at Siemens, the basis builds a future investment into the electronics factory with 3,500 employees as of today, the industrial Metaverse activities as part of the new Digital Experience Centers as well as the additive manufacturing experience center (AMEC). Already today Erlangen is the home for industrial 3D printing and this will be further strengthened to transform Siemens as a user as well as our customers with automation and software solutions on their journey.

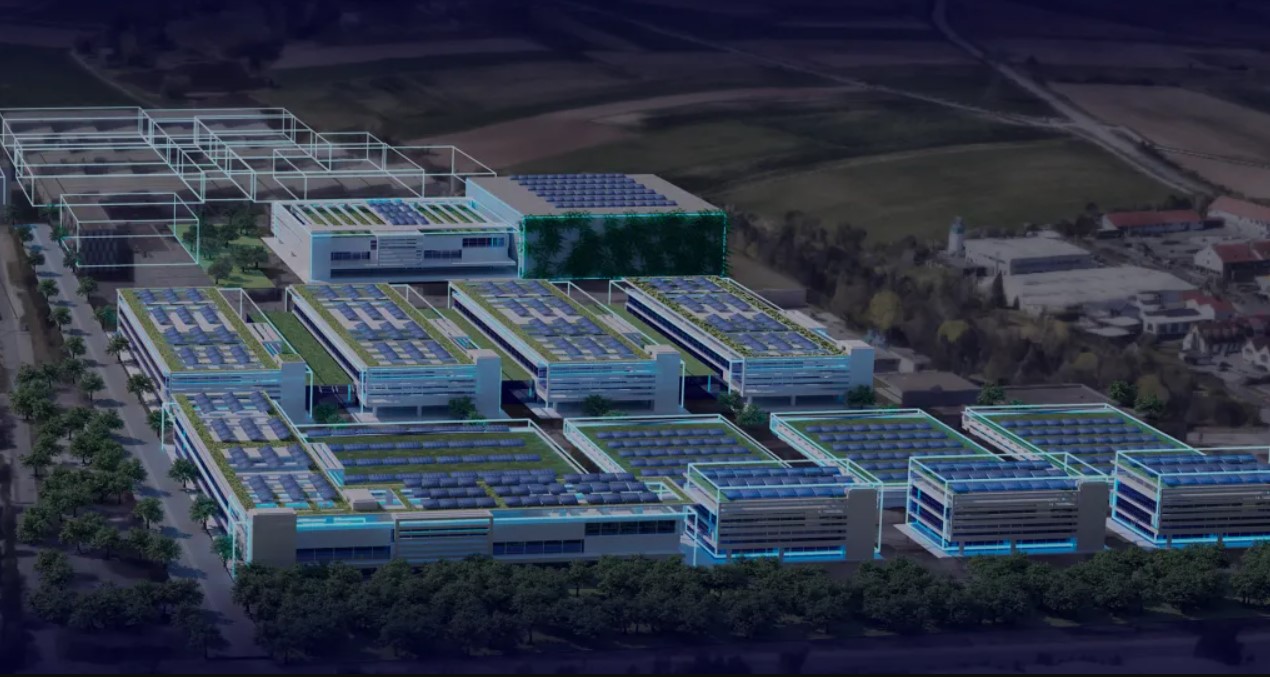

The campus – which is to be built in the west of Erlangen – will focus on sustainable and future-oriented high-tech manufacturing, related research and development activities, and the opening of the location for an ecosystem of partners from the business and scientific communities. The plan for the location also calls for converting existing facilities and expanding the site.

Before construction work begins, the new buildings for research and development, production and logistics will be planned and simulated in the digital world. They will then be implemented in the real world. In the process, an exact replica is created in the digital world, in which the entire existing factory layout is optimized and later readjusted in the real world by using the industrial metaverse. The Erlangen factory manufactures power electronics components and machine tool controls for the machine building industry, which are key elements of Germany’s economy and industry.

The investment is another important element of Siemens’ strategy to combine the real and the digital worlds. The company is strengthening its Erlangen location as a hub for digital production concepts – for example, through the use of the industrial metaverse and for modern technologies like industrial 3D printing and innovative power electronics. In addition, employees are upgrading their skills through forward-looking work and training concepts (NextWork) not only to prepare themselves for the digital transformation of the working world but also to actively shape it.

The announcement follows the $220 million investment for Siemens Mobility’s advanced manufacturing and rail services facility in Lexington, NC.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com