It’s no secret that Additive Manufacturing (AM) has long been hailed as the holy grail of spare parts management across several vertical industries. In theory, the process is quite simple: being able to produce on-demand, sometimes at remote locations an end-use part or a part that can be used as a temporary fix until a regular, conventionally manufactured part arrives. In practice, a remote spare parts management solution requires taking into consideration much more than just an ordinary 3D printer. Although this model fits various industries, the article below will highlight the specific opportunities and limitations that pertain to the automotive industry.

Among the top verticals leveraging spare parts management solutions with Additive Manufacturing, the aerospace and defense industry is on top of the list closely followed by automotive, railway, energy (oil, gas and power generation) as well as maritime.

While specific statistics quantifying the adoption of additive manufacturing (AM) for spare parts management in the automotive industry, in particular, are limited, a recent study reveals that Additive Manufacturing is expected to capture 10% of the spare parts market within five years, driven by its advantages in producing low-volume, complex, and high-performance components.

In the automotive industry in particular, three key arguments are driving the use of AM for spare parts management: cost efficiency for low-demand parts, supply chain optimization as well as restoration of (vintage) vehicles.

Despite these benefits of using AM, the adoption of spare parts management solutions remains limited due to several challenges the technology presents: the access to the digital design data – often linked to IP and legal issues, material considerations, as well as the business case.

Additive Manufacturing has often been criticized for the fact that products have not been designed for the technology in mind, but rather for manufacturing processes like injection molding, CNC machining, or casting.

As such, there may be no original digital data available which means that the engineer will have to identify the design files for the parts needed first, before finding a solution to streamline the workflow, from part design to manufacturing.

Additionally, we need to acknowledge that there are still many materials that deliver reduced mechanical properties when they are printed, 3D printers that can only process one material or even many automotive-grade alloys and composites used in conventional manufacturing are difficult to 3D print.

On top of that, we still need to assess the viability of AM on a case-by-case basis as the technology cost is not often compatible with all scenarios.

As is the case with many challenges faced across other verticals, addressing these technical issues cannot be the sole responsibility of one company; that’s what we learn through the example of Daimler Buses.

Addressing each challenge one collaboration at a time

In the short list of automotive manufacturers who are already betting on AM for spare parts management, one that is leading the way on the road is Daimler Truck | Daimler Buses.

The manufacturer of Mercedes-Benz buses took its first steps with AM in 2017 when it approved its first replacement parts produced with the technology. With over 50,000 3D printable bus spare parts available today, the company mostly uses AM in the after-sales division, to react fast and flexibly to urgent customer requirements, for example when customers order rarely required parts or have special requests.

The company multiplies partnerships that can help its team address the aforementioned challenges faced with the implementation of a viable spare parts management solution. One of the latest partnerships has been signed with 3D Systems and Wibu-Systems – an expert in digital rights and IP management. The company previously worked with Wibu in 2022 to launch its 3D-printed parts shop.

This time, to facilitate remote spare part printing, the three companies join forces to enable Daimler Buses to deliver enhanced service capabilities to its certified additive manufacturing (AM) partners while protecting its valuable intellectual property (IP) and competitive position.

In practice, how 3D Systems’ solutions help Daimler Buses overcome its technical challenges

With over 35 years of expertise in the field, 3D Systems’ offering encompasses everything an industrial needs to operate large-scale manufacturing: hardware, software, materials, and services.

While the company’s solutions serve advanced applications in healthcare and industrial markets, the industry still needs clarity on which solution fits which application.

In this specific case, bus/motorcoach companies or service bureaus that join Daimler Buses’ network of 3D printing certified partners can now purchase a license for 3DXpert through Daimler Buses’ Omniplus 3D-Printing License eShop.

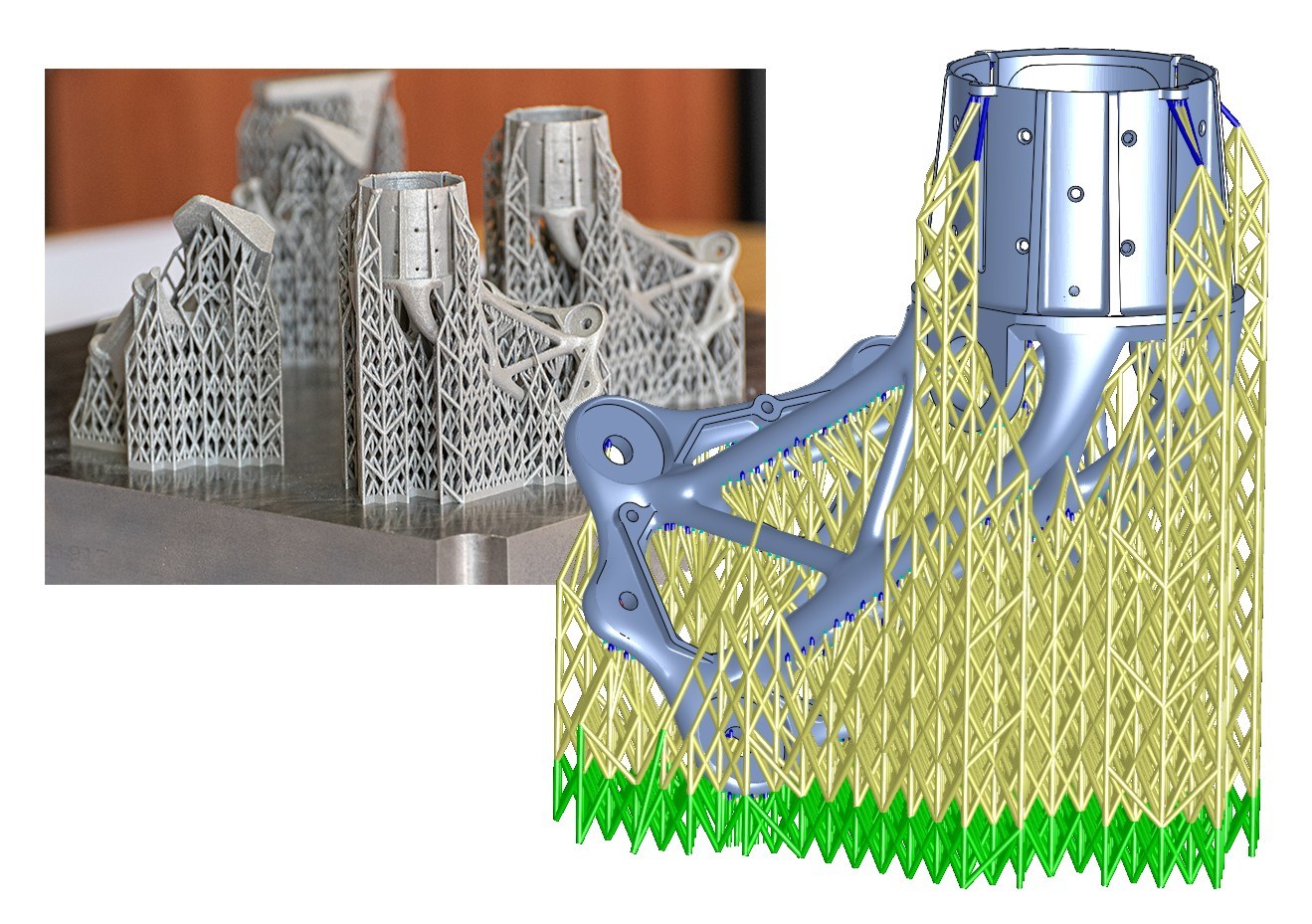

3DXpert is an integrated software for additive manufacturing that simplifies the entire workflow, from part design to printing. Using the 3DXpert platform could easily facilitate access to the digital design data that is often difficult to obtain as the platform enables decrypting the design files for the parts needed for a specific repair job and only produces the exact quantity needed.

Roy Sterenthal, Vice President, Industrial Additive, Oqton commented, “Our 3DXpert software is renowned as an all-in-one solution to streamline the additive manufacturing production workflow. By combining this capability with Wibu-Systems’ robust digital rights management solution, we’re helping Daimler Buses safeguard its intellectual property while accelerating its supply chain. I’m pleased that we can be part of this innovative solution to produce on-demand critical components, reduce reliance on global logistics, and ultimately return vehicles to service faster than ever.”

3D Systems said that currently, the solution is designed to 3D print parts on 3D Systems’ SLS 380. This process-controlled AM solution will help Daimler address material challenges often faced in spare parts management scenarios as it enables the use of multiple materials. This means that the operator can quickly change materials with minimum labor to maximize value and expand application offerings of the SLS 3D printer. Furthermore, a key feature of the SLS solution is the Material Quality Center (MQC), which manages, blends, and delivers materials on demand to ensure an optimal mix of fresh and recycled powder.

“By commercializing this digital service solution, Daimler Buses is not only adopting a new technology; they’re fundamentally reshaping the supply chain for greater resilience and efficiency,” said Jaime Garcia, Additive Solutions Manager – Automotive and Commercial Transportation, 3D Systems. “Our SLS 380 is a high throughput additive manufacturing solution with unprecedented levels of throughput, consistency, performance, and yield. I’m pleased that this is the first 3D Systems technology to be integrated into Daimler Buses’ workflow.”

In the future, Daimler Buses anticipates service bureaus will be able to connect any 3D Systems’ polymer or metal 3D printer to the solution.

Then vs Now

Before this solution was introduced, service providers faced the risk of extended downtime when critical vehicle parts, like three inserts or a fuse box cover, were missing. Due to limitations in local supply chain infrastructure and inventory, not having these parts on hand could lead to delays of weeks, affecting operational efficiency and customer satisfaction. With Daimler Buses’ advanced solution, service providers can now work with nearby service bureaus to rapidly produce the required parts on demand, significantly reducing wait times and improving overall productivity.

Today, Daimler Buses’ certified 3D printing partners can now locally produce spare parts for various under-hood and cabin interior applications, such as pins, covers, and inserts. This enables service partners to boost flexibility and efficiency, reducing the time to receive parts by up to 75%. Additionally, commercial truck, bus, and touring coach companies will benefit from significant indirect cost savings by minimizing vehicle downtime during maintenance.

This content has been created in collaboration with 3D Systems.