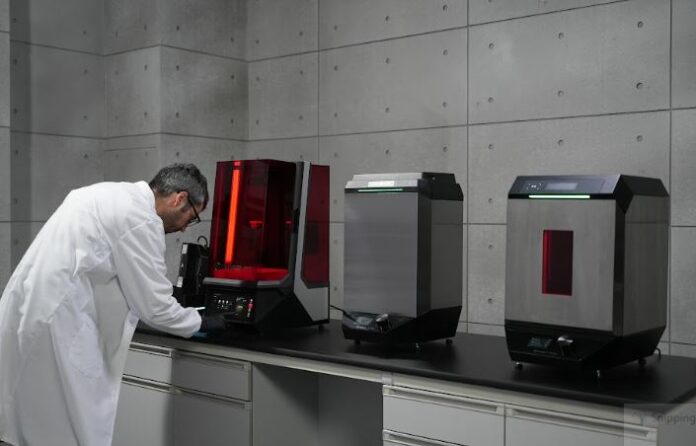

3D printer manufacturer Raise3D has debuted into photopolymer resin 3D printing by unveiling a DF2 Solution at Formnext this year.

The company expanded its 3D printing portfolio with Digital Light Printing (DLP) technology, DF2 Solution which can enhance the printing speeds and refine surfaces all the while maintaining high precision and reliability.

The CEO of Raise 3D Edward Feng said that they made the DF2 Solution “to make resin printing hassle-free for production, with unmatched repeatability, unparalleled quality, and remarkable speed”.

DF2 Solution is designed for prototyping and manufacturing aids in low-volume production with high-grade resins. It has a traceable workflow that reduces labor time and optimizes the use of resin in photopolymer resin 3D printing.

Raise3D DF2 Solution has the following proprietary components to streamline the additive manufacturing workflow:

- DF2 3D Printer: A DLP printer for producing low-volume high-resolution, smooth and repeatable parts due to its Z-Axis lifting system, efficient material management, heated chamber, high quality optical system, advanced Anti-Aliasing technology and Air-Peel technology for fast and easy layer detachment.

- DF Wash: An automated cleaning solution with an efficient process control which has easy cleaning abilities because of twin-turbine washing and hand washing simulation, and a double-fan air drying system. It accommodates various cleaning agents like alcohol, IPA, TPM, and water.

- DF Cure: An advanced curing station equipped with multiple UV curing and heating profiles which can use dual curing sources across multiple wavelengths (365/385/405 nm).

- 3D Resins: A selection of resins tailored for various applications including Tough 2K Resin for optimal load bearing parts used in housing and fixtures, High Detail Resin for direct painting and plating, and Rigid 3K Resin having stiff glass fiber-reinforced thermoplastics property ideal for thin wall parts.

- ideaMaker Slicing Software: This is specially adapted for the DF2 Solution to simplify the DLP printing process with features like antialiasing, auto support, contour compensation, suction cup detection, texture generation, and a reduced Gcode size

DF2 Solution enhances better resin management

Raise3D has partnered with Henkel and BASF Forward AM to develop a resin material strategy suitable for advanced 3D printing. This includes the supply of a wide range of 3D printing materials like LOCTITE 3D IND405™, LOCTITE 3D PRO476™, Ultracur3D® RG 3280, and Ultracur3D® RG 1100 B.

The DF2 Solution is supporting an open material platform allowing customers to explore new possibilities in photopolymer resin 3D printing. The company has launched an Open Resin Program (ORP) which can be used to select the suitable resins needed for making a particular AM part.

The DF2 Solution has advantages like:

- Embedded RFID tags that record the type of resin being used along with recording the washing and curing settings, making way for easy management of washing and curing phases.

- Resin auto refill, and resin material auto recognition along with the Ultrasonic Liquid Level Monitoring and Assisted Resin Tank Cleanup streamlines resin management

- The Raise3D’s Air-Peel technology decreases the peeling force, making layer removal from the film faster during photopolymer resin 3D printing.

The DF2 Solution has 78.5 μm XY Pixel and 2560 x 1440 resolution which makes detailed and smooth prints achievable every time because of the integrated Anti-Aliasing technology.

The smart lattice support in DF2 reduces errors, ensuring high print rate success. It also reduces residual marks in the AM parts which eradicates additional steps of sanding or finishing.

The DF2 Solution has enhanced light engine features for long-lasting use and better image clarity. This includes a DMD chip dedicated for 405 nm 3D Printing and a low-distortion glass lens optimized for DLP technology along with curated LED sources.

Raise3D already started the presale of DF2 Solution from November 7 and customers are availing 10% on orders placed till November 30, 2023.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com