The German 3D Printing service bureau will install the system in September 2019, in its facility in Lupburg. Just like it does with Paulo, the hot isostatic press (HIP) will improve FIT’s productivity by meeting the industrial requirements for 3D printed metal series parts.

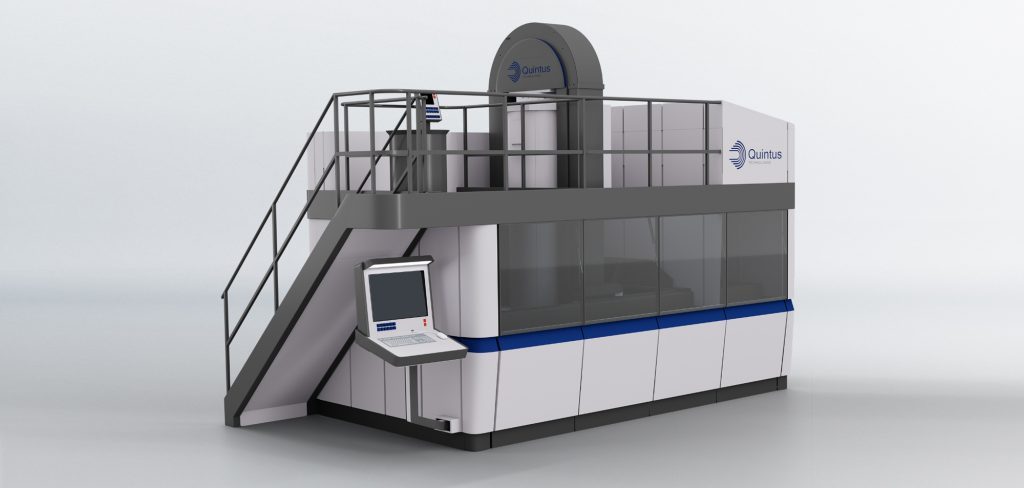

Operating at a temperature of 1400°C (2552°F) and pressure of 30,000 psi (2,070 bar), the press model QIH 32 M URQ® offers a capacity of 120 kg (264 pounds) per load in a work zone that measures 270 mm (10.6 inches) in diameter and 500 mm (19.7) inches in height.

Its proprietary URQ feature allows heat treatment and cooling to be combined in a single process, known as High Pressure Heat Treatment (HPHT). HPHT and HIP are used for the consolidation and densification of metal, ceramic, and plastic parts, producing a maximum theoretical density, ductility, and fatigue resistance in high-performance materials.

“We have evaluated the requirements of 250 international industrial customers for five years, and HIP turned out as an answer to many quality issues,” comments Carl Fruth, CEO, FIT AG. “The results that can be achieved by combining AM and HPHT are highly encouraging. It’s beyond all question that our customers will benefit strongly from this partnership.”

Jan Söderström, CEO, Quintus Technologies, welcomes the cooperation with FIT: “The overall optimization of process parameters and material-specific heat treatment parameters in an in-line, lean-process production context will lead to a new benchmark for dramatically optimized quality levels while reducing costs.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter. Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com