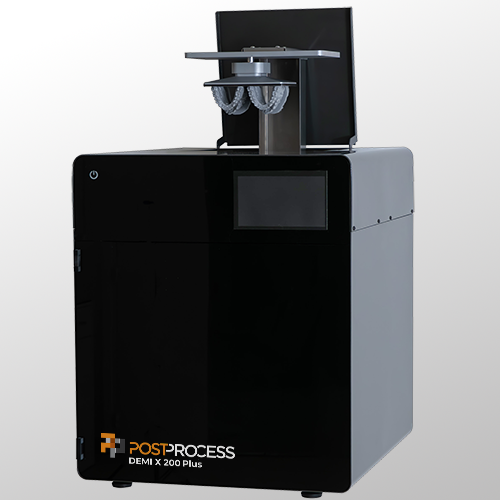

For its latest solution, machine manufacturer Postprocess Technologies decided to integrate resin cleaning, rinsing, drying, and curing into a single compact system.

The new solution called DEMI X 200 Plus, is designed for SLA and DLP 3D printed parts and will support manufacturing workflows of production facilities, dental labs, and service bureaus.

Betting on an all-in-one solution reduces manual labor, ensures consistent quality, and accelerates turnaround times, enabling high-precision parts with enhanced efficiency.

“The launch of the DEMI X 200 Plus marks a significant step forward in our mission to deliver fully automated, intelligent post-printing solutions to the additive manufacturing industry,” said Jeff Mize, CEO of PostProcess Technologies. “This all-in-one system sets a new standard for efficiency, repeatability, and ease of use, enabling our customers to scale their operations with confidence and consistency.”

With the DEMI X 200 Plus, space-constrained, smaller manufacturing facilities and dental labs can now benefit from the advanced all-in-one post-processing solution—eliminating the need for separate rinse baths, compressed air, and curing units. This launch marks a significant step forward in PostProcess Technologies’ mission to revolutionize the post-printing landscape across industries. The DEMI X 200 Plus will initially be offered in Europe and is available to order through the PostProcess Technologies authorized reseller channel., a press release reads.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com