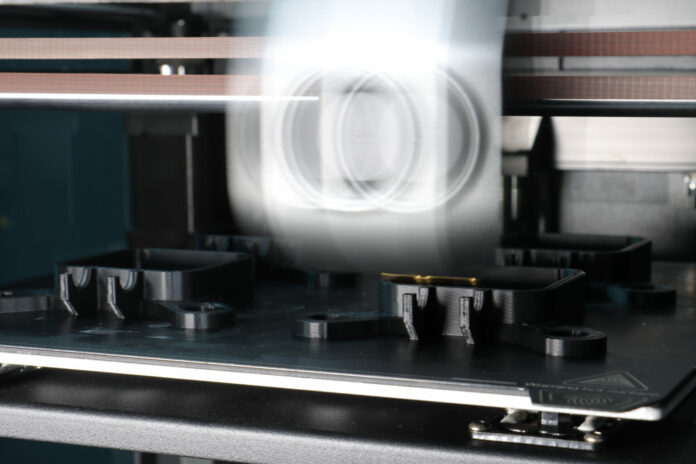

With the growth of high-speed FDM 3D printing segment, material producers need to develop new materials that could keep up with the productivity of these new type of 3D printers. Aware of that, Polymaker has worked on the development of new 3D printing materials: PolySonic™ PLA & PLA Pro.

Extrusion, forming and mechanical properties are three key characteristics of high-speed FDM 3D printing.

As Polymaker explains, PolySonic™ PLA filaments exhibit a wider extrusion window when compared to regular PLA filaments, producing a 30% increase in flow rate at the same printing temperatures when compared to regular PLA filaments. This boost in extrusion efficiency allows users to build profiles with higher printing speeds before noticing the effects of under-extrusion on the printed part.

When it comes to forming, the company scientists have optimized the rheology of the PolySonic™ so that it can transition from fluid to solid with near-zero shrinkage. This produces crisp corners, fine details and steep overhangs while still extruding at high flow rates. Moreover, it significantly enhances actual printing productivity compared to regular PLA, increasing production efficiency by up to 150%.

As for mechanical properties, PolySonic™ PLA shows only a 6% drop in mechanical properties when printing at high speed compared to the classic test specimen. In contrast, PolyLite™ PLA (regular PLA) witnesses a 24% drop when the speed is increased. This final factor allows PolySonic™ to print both fast and functional which has been the previous limitation to high-speed 3D printing. Users can increase the productivity of their machines without compromising on part strength or print quality.

Dr. Xiaofan Luo, Polymaker’s founder, comments: “The latest generation of 3D printers have set a new benchmark for fast printing. But materials are still the missing link. PolySonic is Polymaker’s answer to the new era of high-speed FFF Printing.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com