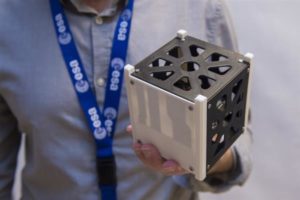

CubeSats bodies are 3D printed by the European Space Agency (ESA) out of a PEEK plastic modified. There are mini satellites developed as educational tools and placed on electronic boards in one or more basic units of 10cm.

Recently, the agency has been working with a robust, stable and solid thermoplastic 3D printing material. It is resistant to temperature and has a melting point of about 370 ° C. Realized in collaboration with the Portuguese company PIEP, Ugo Lafont of ESA explains how they made this PEEK printable electrically conductive.

“This kind of customizing has taken place for as long as the plastic industry has existed. Plastic has been mixed with different materials to tailor their properties as desired, to make them more resistant for instance, or shinier. In this instance, this ‘doped’ PEEK filament can now be used as a standard feedstock in our 3D printing process.”

“This kind of customizing has taken place for as long as the plastic industry has existed. Plastic has been mixed with different materials to tailor their properties as desired, to make them more resistant for instance, or shinier. In this instance, this ‘doped’ PEEK filament can now be used as a standard feedstock in our 3D printing process.”

Stefan Siarov, an ESA trainee who participated in the project, said that the resulting PEEK CubeSat structures would be able to fly in space. However, the bodies “incorporate electrically conductive lines in place of the wire harness normally connecting up the different CubeSat subsystems.”

Thanks to the CubeSats bodies, missions in space could be faster and cheaper. These mini-satellites will be ready for take-off once the solar panels, printed circuit boards and various instruments will have been inserted.