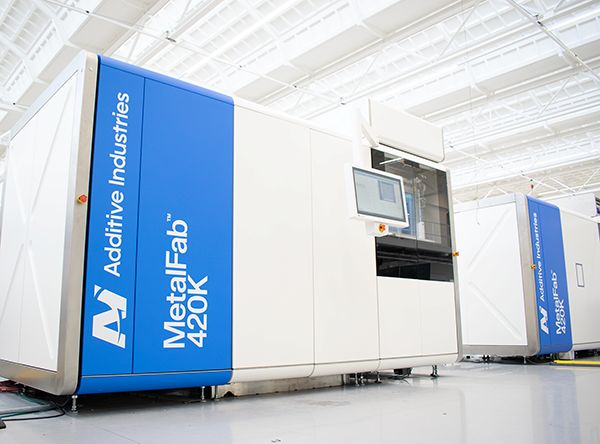

Dutch OEM Additive Industries has launched a new metal 3D printer: the MetalFab 420K system.

Equipped with 1-kilowatt lasers, the powder bed fusion is automated and modular, and features a range of features that aim to ensure quality and productivity for demanding industries.

“Based on the feedback of our valuable global customer base we have built this new system from the proven DNA of our MetalFab product portfolio with a key focus on the needs of our demanding users in the space, aerospace, automotive and high-tech sectors who are looking to push productivity further in their manufacturing operations, where no compromise in quality is acceptable. The MetalFab 420K delivers this,” Mark Massey, CEO of Additive Industries, comments.

Key features

The system features four full-field 1kW lasers, each capable of accessing the entire 420 x 420 x 400 mm build volume. Its optimized, homogeneous, and high-velocity gas flow ensures consistent quality across the powder bed, enabling high laser power and scan speeds without compromise.

A variable beam diameter, calibrated from 100 to 500 μm, allows advanced material and process development. The open architecture provides users with full freedom to create and refine their own process parameters—whether to enhance productivity or to process challenging materials.

Additional features include automated laser calibration with in-build laser-to-laser alignment, and advanced oxygen and humidity controls to minimize powder aging and improve part quality. A new permanent filter design reduces maintenance intervals while enabling improved waste handling without interrupting production. Furthermore, the fully enclosed and automated powder extraction, sieving, and transportation system ensures operator safety and consistent material quality.

Thanks to its modular design, the system allows onsite capacity expansion, supporting enhanced automation (up to eight jobs running automatically without operator input) or greater flexibility (up to three materials installed simultaneously, with multiple AM cores operating in series).

After a rigorous 6 month beta test program, where the system was placed on the production floor of a key US based customer in the space sector, and productivity levels exceeded expectations, the MetalFab 420K is commercially available from today, with orders currently being taken for Q2 delivery slots.

We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.