One of the biggest limitations of desktop FDM 3D printing is that parts often lack the mechanical, thermal, and chemical properties required for demanding applications. This shortfall often stems from low nozzle and chamber temperatures, which restrict material choices, weaken interlayer adhesion, and reduce overall part performance compared to industrial systems.

With nearly a decade of experience in FDM/FFF 3D printing using materials like PEEK, PEKK, ULTEM™, PPSU, and carbon-fiber-reinforced polymers, Vision Miner has consistently helped aerospace, medical, and energy industries achieve production-grade parts with exceptional strength, heat resistance, and chemical durability.

Its latest solution, the 22 IDEX V4 3D printer, is not just another dual-extrusion system — it’s one of the only, if not the only, sub-$40K printer capable of printing true high-performance engineering polymers. Featuring 500 °C nozzles, a 200 °C bed, and a 100 °C actively heated chamber, it brings industrial-grade thermal capability to desktop 3D printing. These high-temperature features also help overcome the technical and operational challenges often associated with IDEX (Independent Dual Extruder) technology. This article discusses how.

Although IDEX (Independent Dual Extruder) technology offers clear advantages such as multi-material printing, mirrored builds, and increased productivity, it is often limited by temperature and material management, software and synchronization issues, as well as maintenance and cost.

The temperature and material management issue

With a business built around polymers that provide exceptional heat and chemical resistance, as well as high strength, it is a logical step for Vision Miner to address material and temperature management issues that may arise with IDEX technology.

While multi-material printing can introduce challenges such as varying shrink rates or adhesion behaviors between polymers, Vision Miner’s high-temperature design helps minimize these effects.

Unlike traditional dual-extrusion printers that share a carriage, independent systems prevent cross-contamination and unwanted marks since each nozzle is parked away from the print area when idle. Maintaining a consistently heated chamber is crucial when printing with high-performance polymers, ensuring even thermal distribution, strong layer bonding, and minimal warping.

“The key challenge was having robust materials that are strong and can operate in many environments. Back in the day, the whole reason we even got into functional materials was because we were developing drone gimbals, heavy-lift kits, and other components for aviation and the drone industry and ABS and PLA just weren’t cutting it.

We needed something that could deliver real, functional performance, but still be accessible and affordable. Anybody can get a hobbyist printer and print PLA, but those parts are weak. On the other end, you can spend over $100,000 on a machine that prints robust materials, but that’s not realistic for most small manufacturers.

So the goal was to lower that barrier to entry, to make it possible for both small and large manufacturers to easily and affordably print high-performance engineering polymers.

The biggest differentiator of the 22 IDEX V4 compared to other IDEX systems on the market is its high-temperature capability. With a 200 °C bed, 500 °C nozzles, and a 100 °C actively heated chamber, you can print the full range of engineering materials, and no other IDEX printers on the market really offer that combination at that price point,’’ Rob Lent, cofounder/ COO of the California-based company, tells 3D ADEPT Media.

With a strong focus on PEEK, PEKK, ULTEM™, PPSU, and other engineering thermoplastics, we trust Vision Miner’s approach because it’s grounded in experience, not theory. The company’s story began in drone manufacturing, a field that pushed their materials and machines to the limit. That hands-on background gave them firsthand insight into the limitations of existing 3D printing systems, and ultimately inspired them to engineer stronger, more reliable solutions for the entire industry.

The software and synchronization issue

Coordinating two independent extruders demands advanced toolpath planning, motion control, and firmware communication to prevent collisions, idle time, or quality defects during tool changes. This complexity multiplies when IDEX printers are networked or scaled for farm-level operations, where centralized monitoring, print scheduling, and data synchronization must account for dual-extruder behavior on multiple machines simultaneously.

Without robust software integration, the very independence that gives IDEX its flexibility can become a barrier to consistency and productivity in larger, connected manufacturing environments.

To overcome these challenges, Vision Miner designed the 22 IDEX V4 3D printer with one of the most open, scalable systems on the market: the Duet electronics platform.

Lent explained that “the Duet motherboard and expansion board are open source, highly trusted, and extremely well-documented, so you can literally use them for just about anything.

If someone wanted to convert the printer into a drawing machine, a mill, or a laser etcher, they could. They can add motors, sensors, or other components because the Duet system is so flexible. That means the 22 IDEX V4 can integrate into virtually any production environment, anywhere in the world, and it can connect to networks via Wi-Fi or Ethernet.”

“For our military and sensitive-industry customers who take data security very seriously, it can also run directly from a PC via Ethernet or USB — no cloud required. So whether it’s connected to a network or completely air-gapped in a secure environment, it’s ready to go,” he adds.

The maintenance and cost issue

Two independent nozzles can double the potential failure points, from clogs and heat creep to misalignment. Additionally, servicing tasks such as replacing hotends or other components are time-consuming, and firmware updates or system diagnostics can be more complex, particularly in industrial setups.

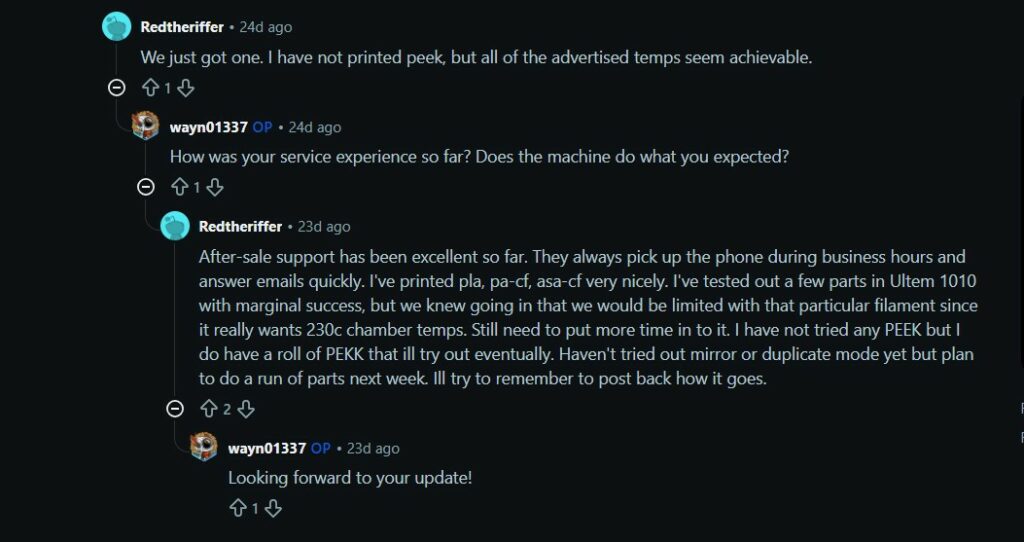

Although more user feedback will be helpful, those who have already tested the machine report that its high-temperature performance is reliable and that Vision Miner provides outstanding after-sales support. This seems obvious when one knows that for many years, Vision Miner’s core business has been selling machines made by other manufacturers to companies working with high-temperature 3D printing materials and then helping clients operate and maintain the machines effectively.

On top of this, although IDEX machines are generally more expensive than single-extruder printers, we initially foresaw a conflict of interest with AON3D systems that Vision Miner also resells. But where we see challenges, Lent sees an opportunity for users to address a wider range of applications. He explains:

“The 22 IDEX V4 brings roughly 80–90 percent of the functionality of a high-temperature industrial printer to manufacturers for about $15,000. But if you need to print a two-foot-tall solid Ultem 1010 part, you’ll need a 250 °C chamber, that’s where the AON3D Hylo™ comes in.

The Hylo™ has a much larger build volume, higher chamber temperatures, and is geared for extreme industrial applications (aerospace, energy, medical devices, and other certified production environments). It also includes advanced sensors and data-logging features, powered by its Basis™ software, for traceability and part certification.

The 22 IDEX V4, on the other hand, covers about 80 percent of real-world applications at a fraction of the cost. For many companies, it’s the practical choice for day-to-day high-temperature printing. Larger organizations often use both: a Hylo™ for oversized or flight-certified parts, and multiple 22 IDEX V4 units for daily production.

The price barrier is the biggest differentiator — around $15–20 k versus $100 k+. The Hylo™ serves a more niche, ultra-high-end market, while the 22 IDEX V4 bridges that gap and makes industrial materials accessible to everyone.”

That said, one of the biggest examples of cost efficiency is with PEEK. The company’s COO shares that many manufacturers — especially in the medical industry — used to buy solid PEEK blocks and mill them down. A small block could cost over $1,000, and most of that material gets wasted. With the 22 IDEX V4, the same part can be printed for around $14 in raw material, saving thousands per part.

“Injection molding isn’t always an option either — materials like PEEK are semi-crystalline and have extreme warping forces, so they can crack molds as they cool. Additive manufacturing bypasses that entirely.

Another example comes from a well-known Japanese automotive manufacturer that uses the 22 IDEX V3 to produce ABS prototypes with soluble supports (HIPS). They use these prints to test injection-molded part designs before committing to tooling — saving hundreds of thousands in mold costs and weeks in lead time.

Dark Matter X, a company that makes performance parts for Subarus, built their entire business using high-temperature nylon-carbon and polycarbonate-carbon materials on our printers. Many of their production parts are now directly printed — hundreds of units — at a fraction of the cost of traditional manufacturing.

In electronics, one customer prints custom wave-solder trays that previously took 2–3 weeks to machine and cost thousands; now they print them overnight for a few hundred dollars.

In aerospace, a client restored a Lockheed Martin Constellation jet by 3D scanning and re-printing the entire HVAC system in ABS, PPS-CF, and PC, all on our printer. Another customer used PEKK to print custom HVAC ducting and cabin component mounts for helicopter retrofits, cutting part costs from hundreds of dollars to under $30 per component,” he completes.

Technical specifications

Running on standard 110 V power, compatible with typical 15 A or 20 A circuits, the 22 IDEX V4 3D printer uses independent dual extruders, allowing multi-material, soluble-support, duplication, and mirror printing. The machine also allows running mixed nozzle sizes simultaneously.

The bed uses a triple-Z-motor system, providing mechanical self-leveling and enabling true 5-axis (3+2) non-planar printing capabilities.

The electronics are Duet-based, with open-source firmware and full documentation. It connects via Wi-Fi or Ethernet, and can also run offline for secure environments.

Other key technical specifications include:

- Triple-motor Z-axis for mechanical self-leveling and true 5-axis (3+2) printing capabilities

- 500 °C nozzles

- 200 °C bed

- 100 °C actively heated chamber

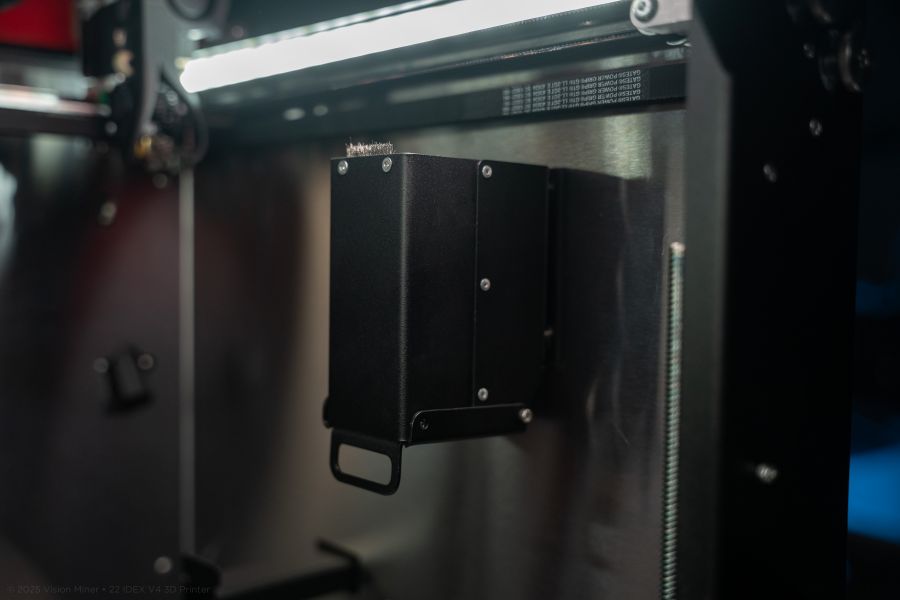

- Triple-wall insulation for heat efficiency

- Custom HEPA + carbon filtration system rated for high-temperature air

- Fully stainless-steel interior and a welded steel frame for rigidity

- Dual-pane front-door glass for better heat retention and user safety.

Vision Miner provides complete documentation, a wiki, videos, and U.S.-based technical support for all users, both domestic and international.

And now?

With well-known IDEX specialists like Essentium and BCN3D no longer in the market, users are seeking a manufacturing-grade platform designed for the shop floor; with maintainability, accessible components, and long-term reliability in mind.

Based on our conversation with Rob Lent and the feedback from early users, the 22 IDEX V4 3D printer emerges as an ideal production candidate. Vision Miner’s mission — to deliver powerful, industrial-grade tools to small businesses while helping large companies scale additive manufacturing efficiently and affordably — positions the 22 IDEX V4 as a technology to watch in the field.

We strongly encourage future users to share the applications they create with high-temperature materials on the 22 IDEX V4 printer, which is now available for commercialization worldwide.

This content has been created in collaboration with Vision Miner.