As part of a series of tests performed with the University of Rostock, AIM3D has been able to assess the performance of the polyamide material PA6GF30 with the Composite Extrusion Modelling (CEM) process.

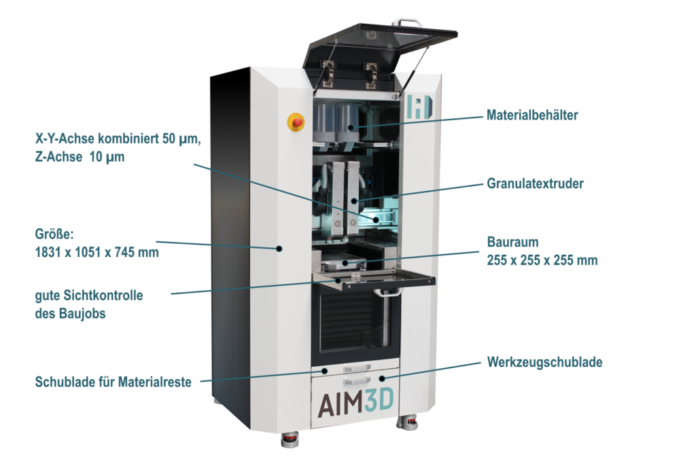

The capabilities of this process have previously been explored with copper as part of a partnership with Schunk.The AIM3D ExAM 255 – a multi-material 3D printer – was also used this time, alongside the ExAM 510 machine.

Ideal for industrial series production applications, PA6GF30 can combine high mechanical properties with temperature and media resistance. According to AIM3D, PA6GF30 components are highly suitable for replacement applications for metal or aluminium parts wherever operating temperatures allow (PA6GF30: 130°C in continuous use, 150°C for short periods).

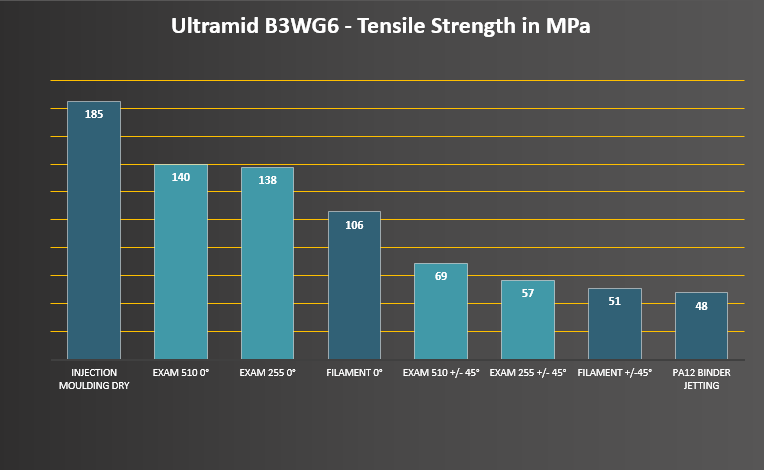

With regard to mechanical properties, such as tensile strength, very high values were obtained by 3D printing on the AIM3D ExAM 255 and ExAM 510 systems (see Graph 1). Compared to powder bed processes or 3D printing processes that use filament materials, the CEM process systems achieve tensile strengths that come close to classic thermoplastic injection moulded processes, the company explains.

Costs analysis: a comparison with a conventional manufacturing approach

As you may know, one thing that might impact the cost is the ability to manufacture in one printing process or not. In this specific case, a motor mount-equipped extruder housing has been manufactured as a demonstration of the process. The motor mount, two air ducts routed in the walls, a ventilation outlet and a mounting for sensors were all integrated into the housing as a single component.

If they had relied on a conventional manufacturing process with milled aluminium parts, 3 to 4 parts would have had to be milled from one block, resulting in a waste of raw materials. Not to mention that additional time would have been necessary during the design phase to devise a workaround to avoid the use of special tools such as slot drills etc. and to implement a suitable form-fitting connection of the parts.

The time spent writing CAM milling programs is also eliminated, especially for small batch production. Manual assembly work is significantly reduced, which also has a positive effect on the cost calculation of the parts.

As a reminder, the CEM process is unique in enabling the use of commercially available granules without filaments where the material procurement costs are the same as for injection moulding yet without the tooling costs.

“Pricing that is comparable to injection moulding for raw materials which do not contain filaments is a tremendous advantage for our CEM 3D printing systems technology. Using PA6GF30, our ExAM 255 machine is able to produce both complex, delicate parts with fine print resolution, as well as large structural components with greater layer thicknesses, resulting in maximum cost-effectiveness with state-of-the-art 3D printing”, Vincent Morrison, CEO of AIM3D states.

That being said, AIM3D recognizes that 3D printing cannot match the cost-savings of injection moulding for medium-sized or large series production runs. Its advantages lie more in the production of smaller batches and bionic design approaches.

When it comes to small to medium-sized production runs and rapid prototyping on the other hand, tooling costs form a disproportionate part of price calculations.

“Aluminium as a material is comparatively expensive because of its energy-intensive production. Aluminium parts are often milled from a solid block. This puts great pressure on pricing. Added to this are the current shortages of raw materials. PA6GF30 material printed with our CEM technology as an alternative production solution creates completely new dimensions in terms of cost efficiencies. This applies all the more when bionic design approaches come into play to increase component performance”, Morrison concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com