Part manufacturers often complain they want bigger 3D printers (understand, printers with bigger build volume size), as they ultimately want to produce parts in one go. And that’s something some machine manufacturers try to address every time they unveil a new 3D printer.

The latest addition to the Sapphire family of 3D printers developed by OEM Velo3D is the Sapphire XC 1MZ, a machine that could fabricate parts one meter in height—with a total build volume that is twice that of the Sapphire XC and nine times larger than the original Sapphire.

Designed based on feedback from customers in the aerospace, energy, and defense industries, the new industrial 3D printer combines Velo3D’s geometric capabilities with the repeatable, standardized processes and validated material properties necessary to achieve distributed manufacturing in a larger format.

“Without advanced metal additive manufacturing it would be difficult to impossible to build many of the technologies that are shaping the future of our world,” said Benny Buller, Velo3D CEO and Founder. “Our innovative customers have a clear understanding of how the technology can unlock new capabilities for their businesses and transform their product offerings. New systems, like the Sapphire XC and Sapphire XC 1MZ, support that transformation by significantly increasing throughput up to 400% and lowering costs by up to 75% compared to the original Sapphire.”

Materials that have been previously qualified for the other Velo3D platforms could also be processed by the new 3D printer. They include for instance, Aluminum F357, Amperprint® 0233 Haynes® 282, GRCop-42, Hastelloy C22, Hastelloy X, Inconel® 625, Inconel® 718, Scalmalloy, and Titanium 6AI-4V Grade 5.

Main technical specifications of the Sapphire XC 1MZ include:

- The largest build volume of any laser powder bed fusion printer in its class—600 mm x 1,000 mm—nine times larger than the original Sapphire and 30% larger than printers from other leading manufacturers

- Eight 1-kilowatt lasers

- An integrated, end-to-end manufacturing solution including Flow print preparation software and Assure quality assurance software

- The Intelligent Fusion manufacturing process that has been proven in production on Sapphire and Sapphire XC for consistent, repeatable results across different printers

- Faster non-contact recoater to decrease the time required between build layers

- Increased throughput of up to 400% over the original Sapphire and Sapphire 1MZ printers

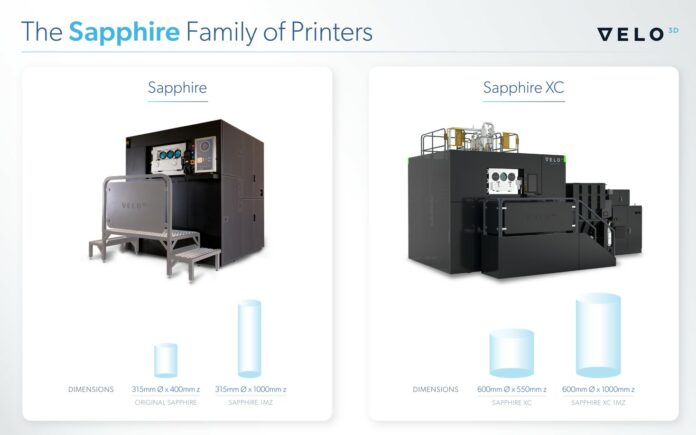

The Sapphire family of printers is comprised of four unique system variations that are fully compatible with one another, running the same processes across all printers in a way that delivers consistent results on any machine. This means that as customers validate one printer for production use, it is simple to add additional printers to increase productivity. The original Sapphire printer is capable of printing parts that are 315 mm in diameter and 400 mm in height. The Sapphire 1MZ prints at 315 mm in diameter and 1 meter in height. The Sapphire XC, which began shipping in Q4 2022, has a build volume of 600 mm in diameter by 550 in height.

The Sapphire XC 1MZ first systems are expected to be delivered to several aerospace companies in late Q3 2022.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com